Preparation method of silicon-carbon negative electrode material for high-compaction-density lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, nanotechnology for materials and surface science, secondary batteries, etc., can solve the problem of quickness, insufficient simplicity of the method, and compaction density of silicon-carbon negative electrode materials To achieve the effect of rich raw materials, improved comprehensive performance and wide range of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

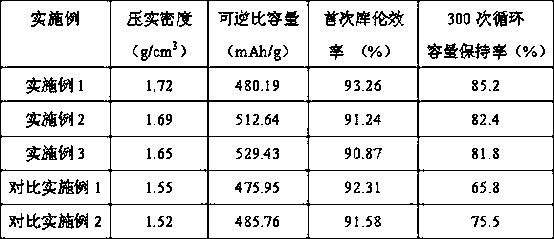

Examples

Embodiment 1

[0032] (1) Add D50=5μm polysilicon and zirconia balls into the zirconia ball milling tank according to the mass ratio of 3:1, and add a certain amount of absolute ethanol at the same time. The mass ratio of ethanol to polysilicon powder is 1:1. Rotate forward at 500 rpm for 30 minutes and then stand still for 5 minutes. After standing still, reverse at 500 rpm for 30 minutes, continue to stand for 5 minutes, and then continue to rotate forward. Reciprocate in this way to meet the total ball milling time of 12 hours. After the ball milling is completed, zirconia balls and silicon powder are separated through a screen to obtain nano-scale silicon powder with D50=100nm.

[0033] (2) Add porous natural graphite to the ball mill tank, continue to add zirconia balls at a mass ratio of material: zirconia balls = 1:3, and run the ball mill at 300 rpm for 3 hours to obtain a micron-sized porous natural stone with D50=10μm toner.

[0034] (3) Add the uniform nano-silicon powder obtaine...

Embodiment 2

[0039] (1) Add D50=5μm polysilicon and zirconia balls into the zirconia ball milling tank according to the mass ratio of 3:1, and add a certain amount of absolute ethanol at the same time. The mass ratio of ethanol to polysilicon powder is 1:1. Rotate forward at 500 rpm for 30 minutes and then stand still for 5 minutes. After standing still, reverse at 500 rpm for 30 minutes, continue to stand for 5 minutes, and then continue to rotate forward. Reciprocate in this way to meet the total ball milling time of 12 hours. After the ball milling is completed, zirconia balls and silicon powder are separated through a screen to obtain nano-scale silicon powder with D50=200nm.

[0040] (2) Add porous natural graphite to the ball mill tank, continue to add zirconia balls at a mass ratio of material: zirconia balls = 1:3, and run the ball mill at 300 rpm for 3 hours to obtain a micron-sized porous natural stone with D50=10μm toner.

[0041] (3) Add the uniform nano-silicon powder obtaine...

Embodiment 3

[0046] (1) Add D50=5μm polysilicon and zirconia balls into the zirconia ball milling tank according to the mass ratio of 3:1, and add a certain amount of absolute ethanol at the same time. The mass ratio of ethanol to polysilicon powder is 1:1. Rotate forward at 500 rpm for 30 minutes and then stand still for 5 minutes. After standing still, reverse at 500 rpm for 30 minutes, continue to stand for 5 minutes, and then continue to rotate forward. Reciprocate in this way to meet the total ball milling time of 12 hours. After the ball milling is completed, zirconia balls and silicon powder are separated through a screen to obtain nano-scale silicon powder with D50=200nm.

[0047] (2) Add porous natural graphite to the ball mill tank, continue to add zirconia balls at a mass ratio of material: zirconia balls = 1:3, and run the ball mill at 300 rpm for 3 hours to obtain a micron-sized porous natural stone with D50=10μm toner.

[0048] (3) Add the uniform nano-silicon powder obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com