Conductive agent combined type lithium ion battery positive pole piece and manufacture method thereof

A technology for lithium-ion batteries and positive pole pieces, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as low compaction density, low Coulombic efficiency, and easy agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

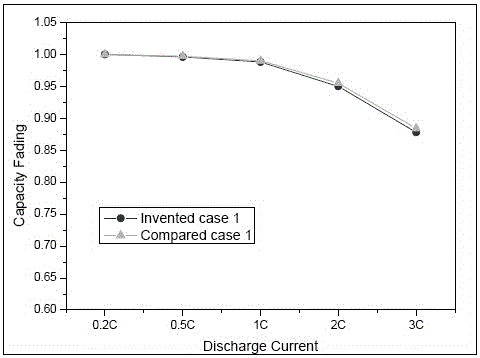

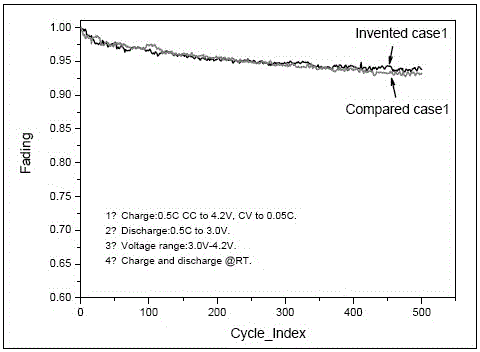

[0035] A positive electrode sheet of a conductive agent combined lithium ion battery comprises a current collector and a positive coating film adhering to the current collector. The components of the positive coating film include a positive electrode active material, a conductive agent and a binding agent. The conductive agent is a combination of CB and CNTs. The positive electrode active material is lithium cobalt oxide. The binder is polyvinylidene fluoride. The solvent is N-methylpyrrolidone. The CNTs are single-walled carbon nanotubes. The CB is Super P.

[0036] The preparation method of the positive pole piece: Dissolve 8.7 grams of polyvinylidene fluoride (Solvay 5130, France) in about 150 grams of N-methylpyrrolidone solvent to prepare a binder solution; then add 122.2 grams of CNTs dispersion slurry (CNTs content 5%, Zhenjiang Tiannai) and 3.6 grams of Super P, mixed thoroughly; then 1000 grams of lithium cobaltate (Tianjin Bamo) was added to the above solution, f...

Embodiment 2

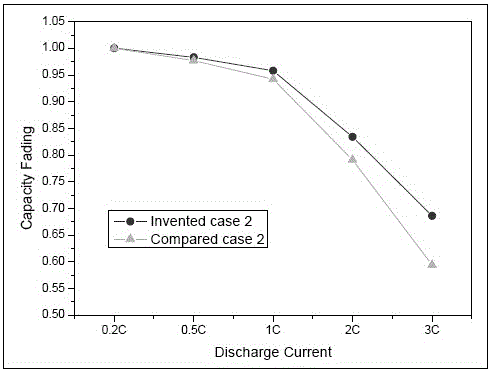

[0048] A positive electrode sheet of a conductive agent combined lithium ion battery comprises a current collector and a positive coating film adhering to the current collector. The components of the positive coating film include a positive electrode active material, a conductive agent and a binding agent. The conductive agent is a combination of CNTs and GNPs. The positive electrode active material is lithium nickel cobalt manganese oxide. The binder is polyvinylidene fluoride. The solvent is N-methylpyrrolidone. The CNTs are single-walled carbon nanotubes. The GNPs are bilayer graphene.

[0049] The preparation method of the positive pole piece: Dissolve 8.65 grams of polyvinylidene fluoride (Solvay 5130) in about 250 grams of N-methylpyrrolidone solvent to prepare a binder solution; then add 111.9 grams of CNTs dispersion slurry (CNTs content 5 %, Zhenjiang Tiannai) and 61.0 grams of GNPs dispersion slurry (GNPs content 5%, Ningbo Mexico), and mix well; then add 1000 gr...

Embodiment 3

[0061] A positive electrode sheet of a conductive agent combined lithium ion battery comprises a current collector and a positive coating film adhering to the current collector. The components of the positive coating film include a positive electrode active material, a conductive agent and a binding agent. The conductive agent is a combination of CB, CNTs and GNPs. The positive electrode active material is lithium nickel cobalt aluminate. The binder is polyvinylidene fluoride. The solvent is N-methylpyrrolidone. The CB is Super P. The CNTs are single-walled carbon nanotubes. The GNPs are multilayer graphene.

[0062] The preparation method of the positive pole piece: Dissolve 8.6 grams of polyvinylidene fluoride (Solvay 5130) in about 250 grams of N-methylpyrrolidone solvent to prepare a binder solution; then add 1.5 grams of Super P and 60.8 grams of CNTs dispersion slurry material (CNTs content 5%, Zhenjiang Tiannai), and 20.2 grams of GNPs dispersion slurry (GNPs conte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com