Lithium ion battery positive plate capable of supplementing lithium and lithium ion battery

A technology for lithium-ion batteries and positive pole pieces, applied in battery electrodes, secondary batteries, secondary battery repair/maintenance, etc., can solve the problems of high reactivity, flammability, and splashing of metallic lithium, and improve cycle capacity Effects of retention rate, high energy density, and high first-time efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

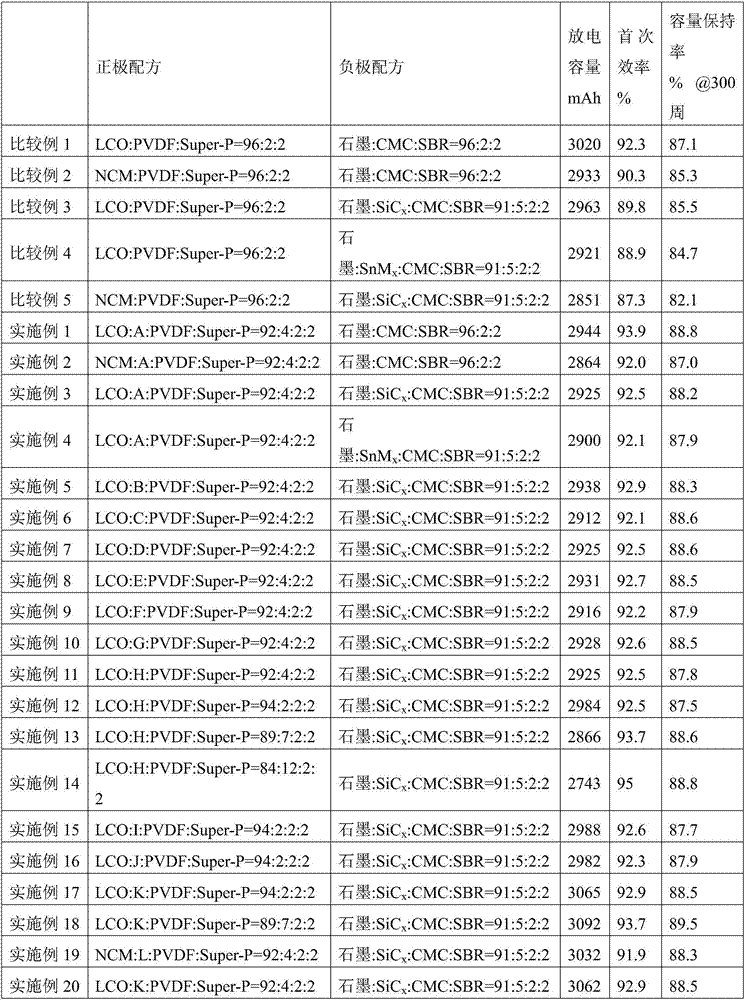

[0033] Preparation of positive electrode sheet:

[0034] (1) Comparative example:

[0035] The positive electrode active material lithium cobalt oxide (LCO) or lithium nickel manganese cobalt oxide (NCM), the binder polyvinylidene fluoride (PVDF) and the conductive agent Super-P are added to the N-formaldehyde according to the weight ratio in the positive electrode formula in the following table Stir and homogenize in NMP to make a positive electrode slurry; apply the positive electrode slurry on both sides of the positive electrode current collector, and obtain the positive electrode sheet after drying, compacting, slitting, cutting, and welding the tabs .

[0036] (2) Embodiment:

[0037] The positive electrode active material lithium cobalt oxide (LCO) or lithium nickel manganese cobalt oxide (NCM), binder polyvinylidene fluoride (PVDF), conductive agent Super-P and lithium supplement additives are added according to the weight ratio in the positive electrode formula in t...

Embodiment 20

[0066] The preparation method of the positive electrode sheet in Example 20: mix the particles of H, conductive carbon black, and PVDF binder, wherein the weight ratio of conductive carbon black is 0-5%, and the weight ratio of PVDF is 1-10%, Add to N-methylpyrrolidone (NMP) to stir and homogenize the additive slurry, and coat and dry the surface of the positive electrode current collector foil to form a thin film of H, and then coat the positive electrode slurry on top of this coating A thin film composed of H is deposited on the surface of the positive electrode current collector foil by vapor phase chemical deposition, and then the positive electrode slurry is coated on the coating. For other battery preparation steps, refer to the battery preparation instructions.

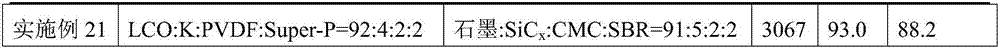

Embodiment 21

[0067] The preparation method of the positive electrode sheet in Example 21: First, refer to the steps in the battery production instructions to coat the positive electrode slurry on the positive electrode current collector on both sides. After drying, mix the particles with the component H, conductive carbon black, and PVDF binder. , wherein the weight ratio of conductive carbon black is 0 to 5%, and the weight ratio of PVDF is 1 to 10%, which is added to N-methylpyrrolidone (NMP) and stirred and homogenized to make additive slurry, and coated on the surface of the positive electrode Cover and dry to form a thin film of H. For other battery preparation steps, refer to the battery preparation instructions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com