Lithium-rich manganese-based positive electrode material and preparation method thereof, and lithium ion battery

A lithium-ion battery, lithium-rich manganese-based technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of insignificant change in particle size, easy generation of impurity phases, and the occurrence of impurity phases, so as to reduce irreversible release and crystallization. Good sex, reduce the effect of activation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

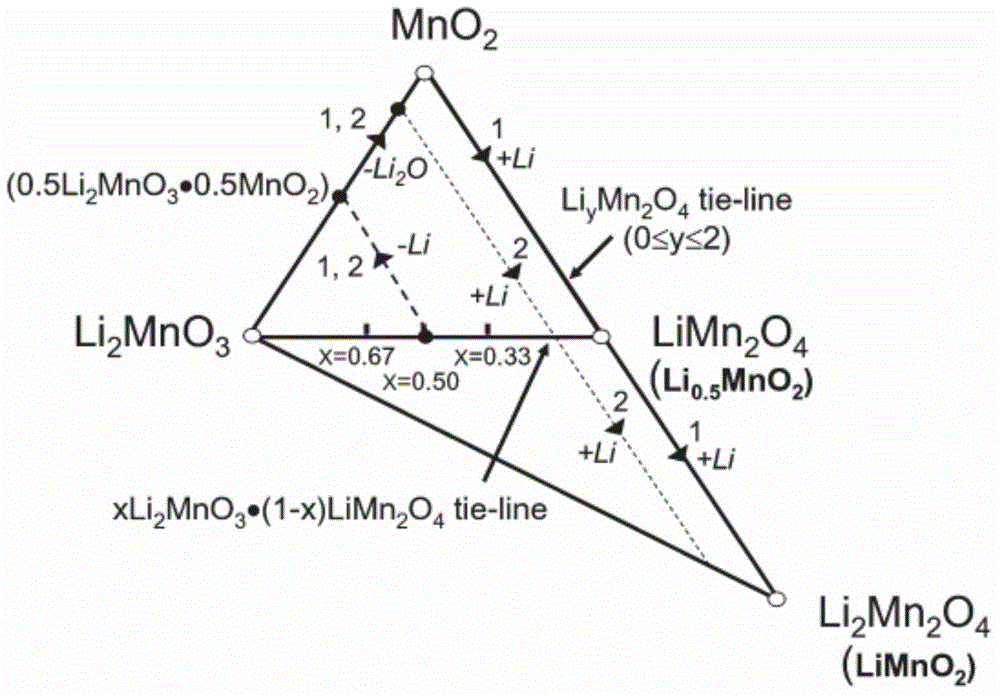

[0066] The present invention also provides a method for preparing lithium-rich manganese-based cathode material, which includes the following steps:

[0067] a) Mixing the lithium source, the manganese source and the doping metal source and heating to obtain a manganese-based material;

[0068] The manganese-based material has the general formula shown in formula (III):

[0069] LiMn a M b O 4 Formula (III);

[0070] In formula (III), M is one or more of nickel, cobalt, iron, magnesium, titanium, aluminum and vanadium;

[0071] 1

[0072] b) Mixing the above-mentioned manganese-based material with a lithium source and sintering to obtain a lithium-rich manganese-based cathode material; the lithium-rich manganese-based cathode material has the general formula shown in formula (I):

[0073] Li 1+x Mn y M z O 2 Formula (I);

[0074] In formula (I), M is one or more of nickel, cobalt, iron, magnesium, titanium, aluminum and vanadium;

[0075] 0

Embodiment 1

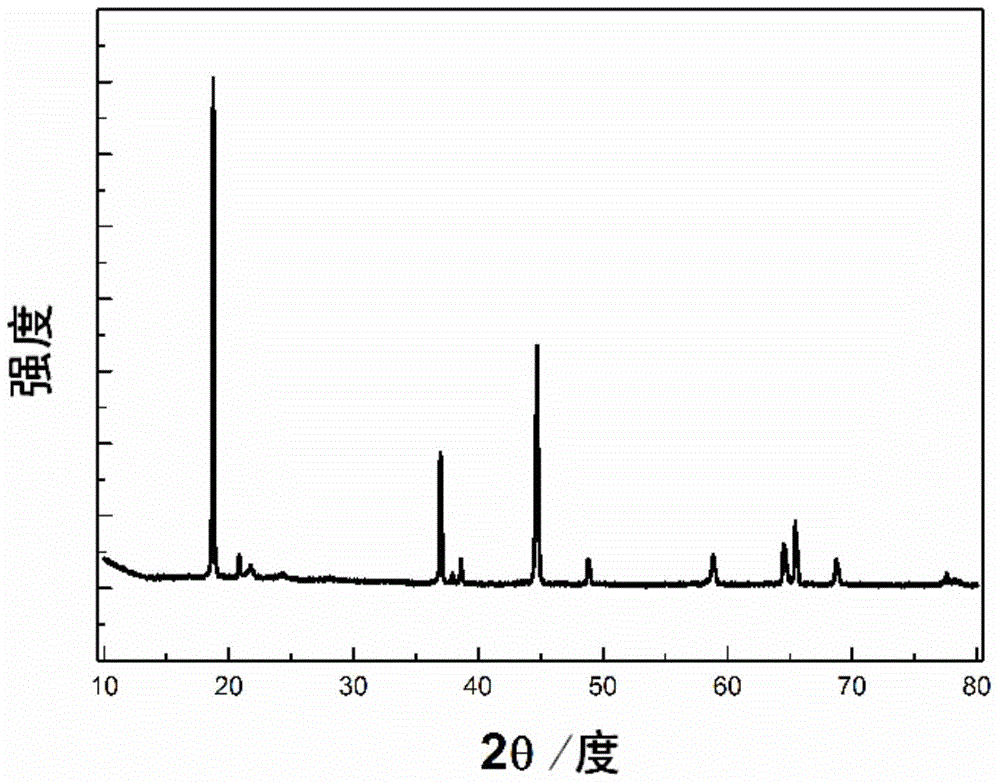

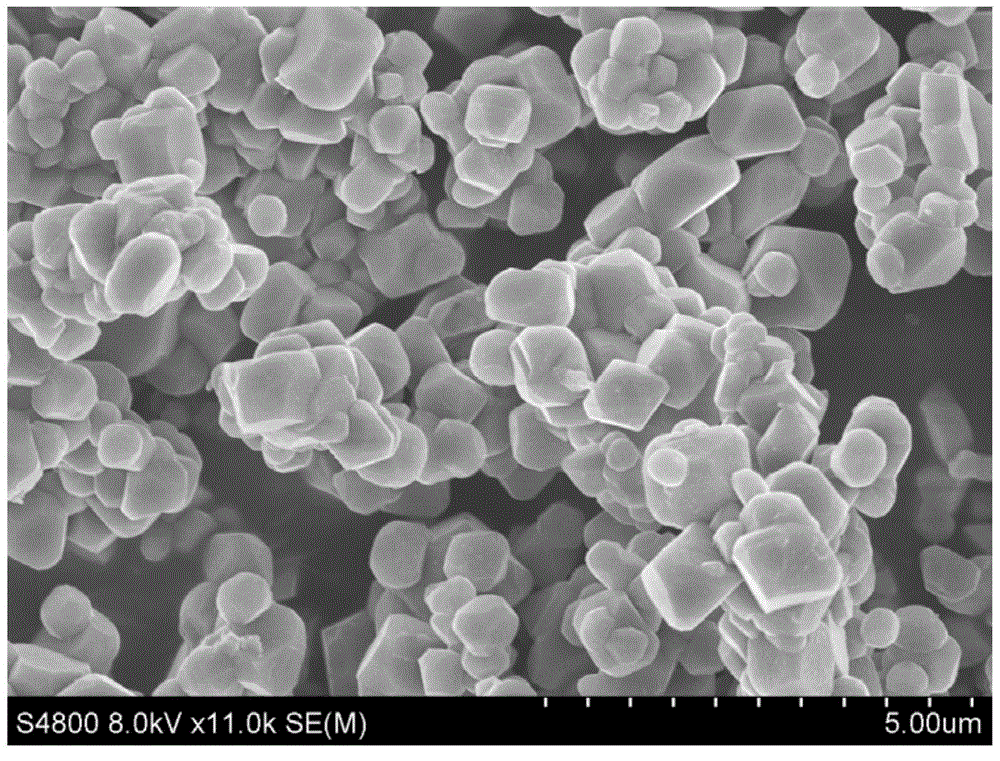

[0144] (1) First, dissolve lithium acetate, nickel acetate, cobalt acetate and manganese acetate with a molar ratio of 1:1:1:6 in deionized water to obtain solution A; at the same time, combine citric acid with a molar ratio of 3:2 and Ethylenediaminetetraacetic acid (EDTA) is dissolved in 25%-28% ammonia water to obtain solution B; secondly, solution A is slowly added dropwise to solution B, and the pH is adjusted to 8 with ammonia water to make citric acid and solution A The molar ratio of metal ions is 1.5:1; then the above mixed solution is heated in an oil bath at 90°C for 18h to obtain a mixture gel; finally the mixture gel is dried and ground, and then sintered at 400°C to 550°C 3h~5h, then sintered at 900℃ for 20h to obtain manganese-based material LiNi 1 / 3 Co 1 / 3 Mn 4 / 3 O 4 .

[0145] (2) After mixing the manganese-based material with a molar ratio of 95:100 and lithium carbonate uniformly, sintering it at 900°C for 20 hours to obtain lithium-rich manganese-based cathode...

Embodiment 2

[0150] (1) First, dissolve lithium acetate, nickel acetate, cobalt acetate and manganese acetate with a molar ratio of 1:1:1:6 in deionized water to obtain solution A; at the same time, combine citric acid with a molar ratio of 1:4 and Ethylene glycol was mixed with deionized water to obtain solution B; secondly, solution A was slowly added dropwise to solution B so that the molar ratio of citric acid to metal ions in solution A was 1:1; then the above mixed solution was heated at 80°C Heated in an oil bath for 1 hour, and then heated in an oil bath at 140°C for 1 hour to obtain a mixture gel; finally, after drying and grinding the mixture gel, it is sintered at 400℃~550℃ for 3h~5h, and then at 800℃ Sintered for 48h to obtain manganese-based material LiNi 1 / 3 Co 1 / 3 Mn 4 / 3 O 4 .

[0151] (2) After mixing the manganese-based material with a molar ratio of 9:10 and lithium carbonate uniformly, sintering at 850°C for 20 hours to obtain lithium-rich manganese-based cathode material L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com