Caulking asphalt for roads and bridges, and preparation method for caulking asphalt

A kind of asphalt, road and bridge technology, applied in the field of asphalt and its preparation, can solve the problems that affect the quality and service life of road and bridge decks, cannot effectively prevent rainwater from leaking into the base layer, and has not formed commercial production, etc., and achieves good elastic recovery performance and needle penetration The effect of moderate degree and high softening point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

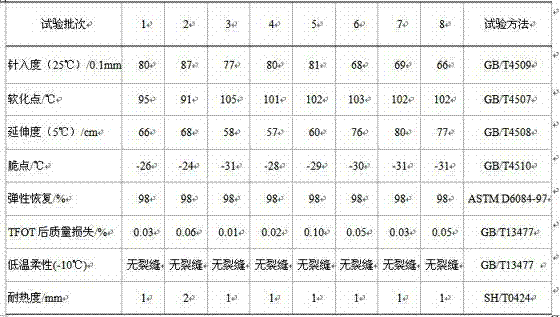

Examples

Embodiment 1

[0048] The road and bridge caulking asphalt provided in this embodiment contains the following raw materials: 450 grams (75%, mass percentage, the same below) of 90# base asphalt, 30 grams (5%, Mass percentage, the same below), polymer A (SBS F420) 30 grams (5%, mass percentage, the same below), polymer B (thermoplastic polyurethane elastomer TPU 85A) 90 grams (15%, mass percentage content, the same below).

[0049] Above-mentioned raw material is prepared according to the following method and obtains road and bridge caulking asphalt of the present invention:

[0050] (1) Heat 450 grams of 90# base asphalt to 140°C;

[0051] (2) Add 30 grams of compatibilizer (minus four-extraction oil), add 30 grams of polymer A (SBS F420) and add 90 grams of polymer B (thermoplastic polyurethane elastomer TPU 85A), and pre-mix for 45 minutes with increased agitation , temperature control 180°C;

[0052] (3) Then move to a high-shear mixer and stir for 30 minutes, the mixer speed is 4000 r...

Embodiment 2

[0055] The road and bridge caulking asphalt provided in this example is made of the following raw materials: 450 grams (75%) of 90# base asphalt, 30 grams (5%) of compatibilizer (minus four extraction oil), polymer A (SBS F501) 60g (10%), Polymer B (TPU 85A) 60g (10%).

[0056] Above-mentioned raw material is prepared according to the following method and obtains road and bridge caulking asphalt of the present invention:

[0057] (1) Heat 450 grams of 90# base asphalt to 150°C;

[0058] (2) Add 30 grams of compatibilizer (minus four-extracted oil), add 60 grams of polymer A (SBS F501) and 60 grams of polymer B (TPU 85A), increase the stirring and pre-mix for 60 minutes, and control the temperature at 190°C ;

[0059] (3) Then move to a high-shear mixer and stir for 30 minutes, the mixer speed is 6000r / min, and the stirring temperature is 200°C, so that polymer A and polymer B are evenly dispersed in the asphalt;

[0060] (4) Continue to stir for about 120 minutes, and control...

Embodiment 3

[0062] The road and bridge caulking asphalt provided in this embodiment contains the following raw materials: 432 grams (72%) of 70# base asphalt, 60 grams (10%) of a compatibilizer (specifically minus four extraction oils), polymer A (SBS F420 ) 72 g (12%), polymer B (TPU 85A) 30 g (5%), stabilizer (magnesium oxide) 6 g (1%).

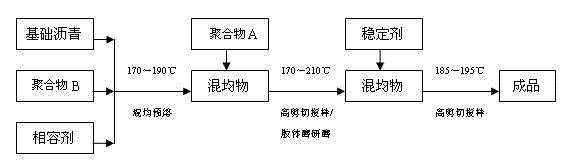

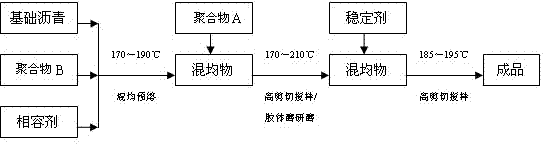

[0063] as attached figure 1 Shown, above-mentioned raw material is prepared according to the following method and obtains road and bridge caulking asphalt of the present invention:

[0064] (1) Heat 432 grams of 70# base asphalt to 170°C;

[0065] (2) Add 60 grams of compatibilizer, add 72 grams of polymer A and 30 grams of polymer B, premix with increased force for 60 minutes, and control the temperature at 200°C;

[0066] (3) Then move to a high-shear mixer and stir for 60 minutes, the mixer speed is 5000r / min, and the stirring temperature is 200°C, so that polymer A and polymer B are evenly dispersed in the asphalt;

[0067] (4) Add 6 grams of st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Liquidity | aaaaa | aaaaa |

| Stretch | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com