Backward thrust and negative pressure combined adsorption method for wall climbing robot and implementation thereof

A wall-climbing robot and composite adsorption technology, which is applied in the fields of motor vehicles, transportation and packaging, etc., can solve the problems of weak obstacle-crossing ability, difficult realization, poor mobility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

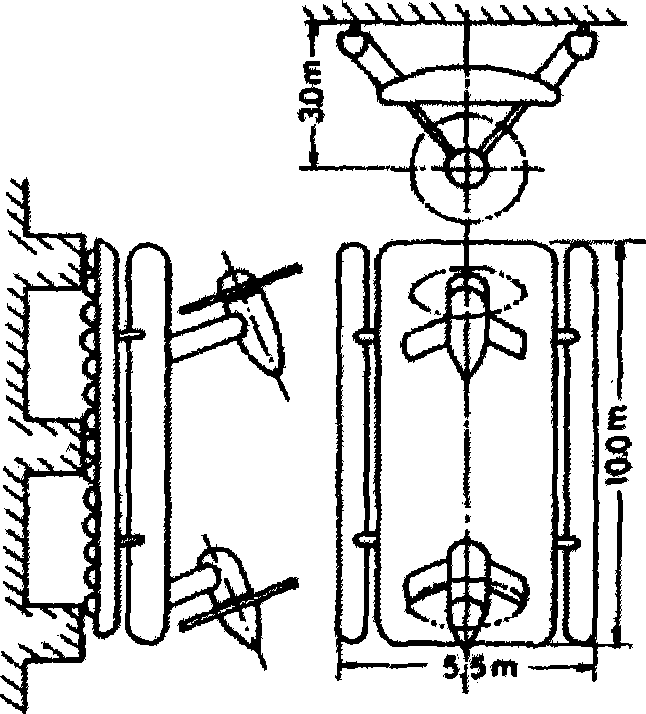

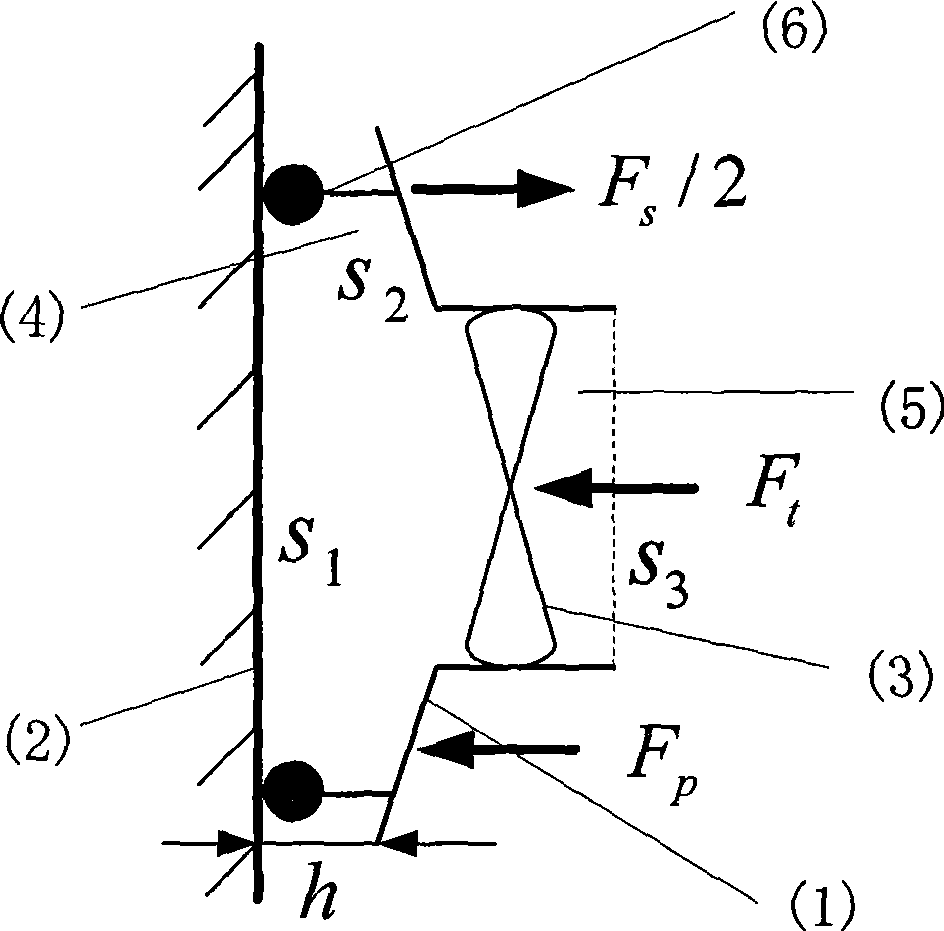

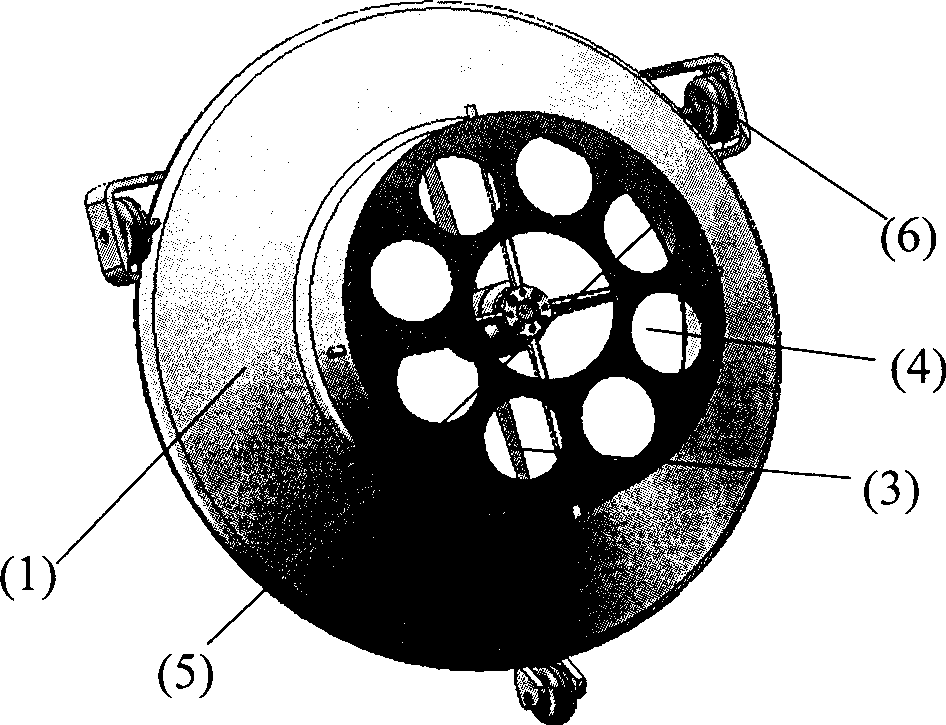

[0037] When this method is used for wall-climbing robots, combined with the attached figure 2 , attached image 3 And attached Figure 4, one implementation can be described as: the axis of the propeller is perpendicular to the wall, used to provide axial airflow and reverse thrust, the suction cup located at the inflow of the propeller is used to provide negative pressure suction, and the suction cup has a negative pressure chamber and The diversion duct, the propeller is located in the diversion duct, and is connected with the output shaft of the motor, and the suction cup is seamlessly connected with the diversion duct opening. When the sucker 1 of the wall-climbing robot is in working condition on the wall 2, the propeller motor drives the propeller 3 installed in the diversion duct 5 to rotate at a high speed, so that the air flow enters the negative pressure chamber 4 of the sucker from the gap between the sucker 1 and the wall 2 , and discharged through the diversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com