Method for dehydrating furfural by pervaporation of NaA zeolite molecular sieve membrane

A zeolite molecular sieve membrane and pervaporation technology, applied in the field of chemical engineering, can solve the problem of separation without research reports, and achieve the effects of expanding the application field, improving the grade, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

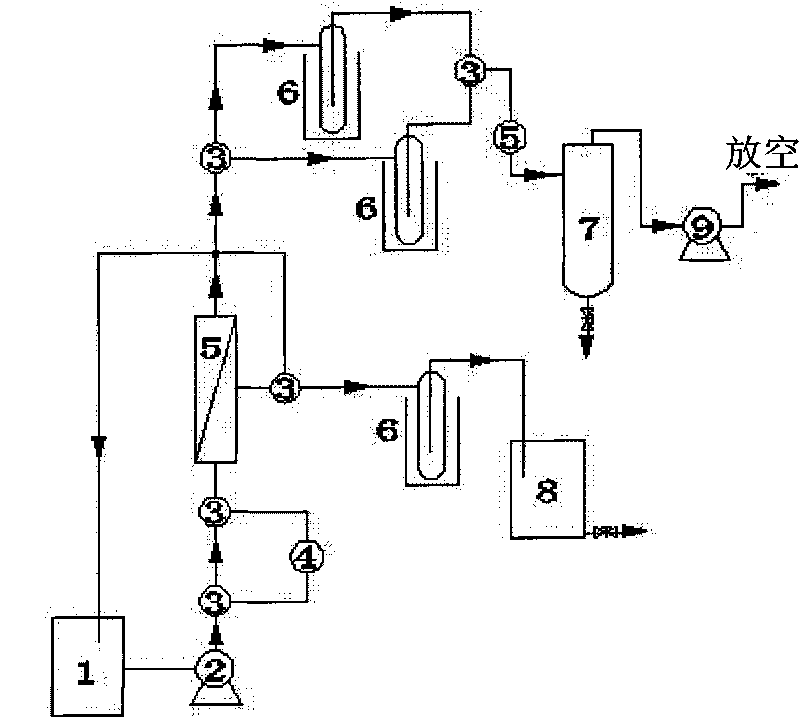

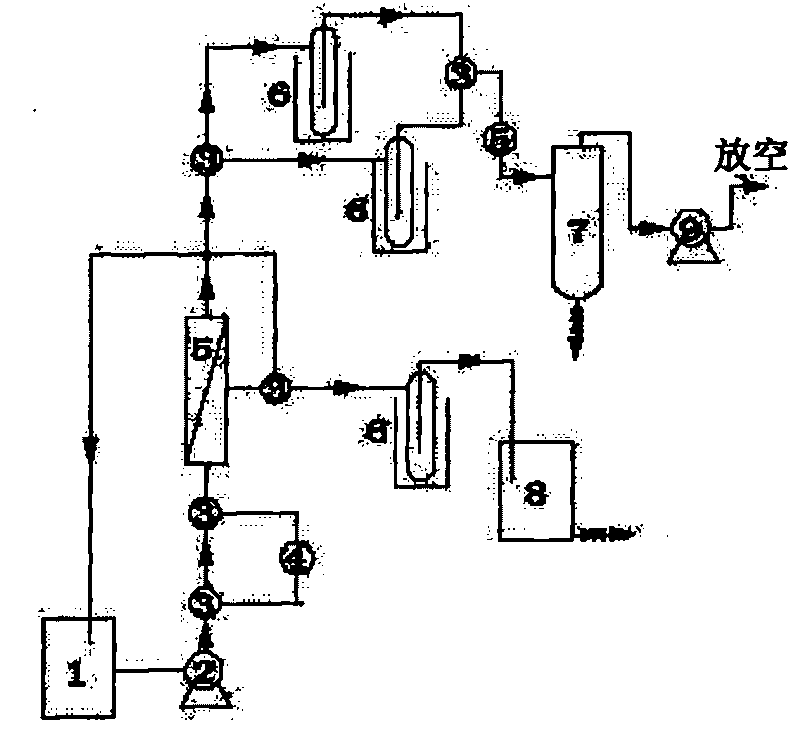

Image

Examples

Embodiment

[0018] Preparation of NaA molecular sieve membrane synthesis solution: 6.80g NaAlO in a 200ml beaker 2 (including Al 2 o 3 wt.% = 50.0 wt.%, Na 2 (0 wt.%=38.0 wt.%) and 2.072g NaOH were fully dissolved in 107.875g water, stirred vigorously for 1h, and then 15.385g silica sol (SiO 2 wt.% = 26.0 wt.%, Na 2 O=0.05%) was slowly added to the above-stirred aluminate, and then continued to stir for 3 hours to prepare a white milky sol synthesis liquid.

[0019] Carrier pretreatment: the surface of the carrier is sequentially washed with 600 # and 800 # Sandpaper the outer surface until the surface of the carrier is smooth, soak in alkali for 24 hours each, then use ultrasonic vibration to wash away the residual alkali in the pores, then wash with deionized water until neutral, then dry naturally, and finally dry at 423K for later use.

[0020] Preparation of the seed crystal layer of the carrier: prepare the prepared nano-scale NaA molecular sieve into a 1.0wt.% seed crystal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com