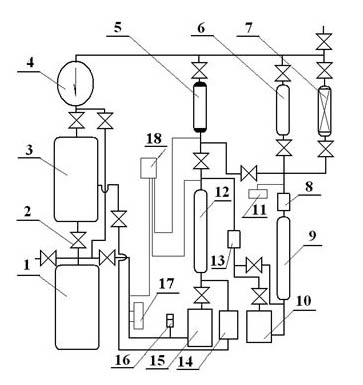

Low-temperature displacement chromatography hydrogen isotope separation device and method

A technology of hydrogen isotope and displacement chromatography, applied in hydrogen isotope, separation method, separation of different isotope elements, etc., can solve the problems of bad changes in hydrogen absorption characteristics, high energy consumption in the separation process, and short effective life of the separation column.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

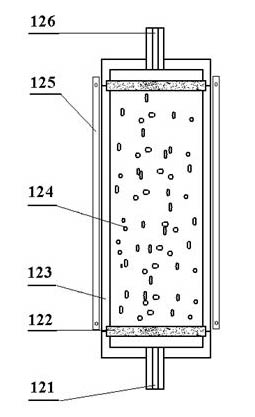

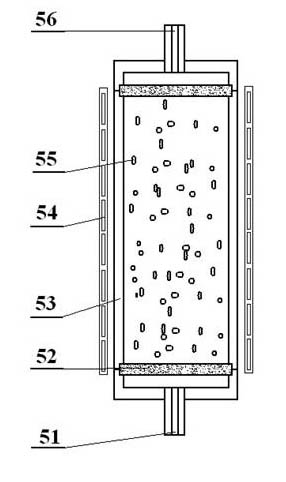

[0080] The main parameters of the separation device in the following examples: 1) Main separation column: length 5m, diameter Φ14??2mm; 2) Displacement chromatographic separation material: Palladium loaded alumina (Al 2 o 3 -Pd), Pd weight percentage 45%, particle diameter Φ5mm; packing method, loose packing.

[0081] On the separation device, the raw material gas composition is: 5%H 2 +5%D 2 +90%He, 1.07%D 2 -9.22%H 2 -89.71%He, 27.67%D 2 -28.70%H 2 -43.63%He and 49.98%D 2 -50.02%H 2 The mixed gas, under the conditions of the separation column temperature of -10°C, -20°C, -60°C, -100°C and -196°C, respectively, according to the separation steps 1 and 1 in the low temperature displacement chromatography hydrogen isotope separation method of the present invention Separation step 2, separation step 3 and separation step 4 implement separation. For various embodiments, the operating temperature of the primary separation column and the temperature of the secondary separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com