High-flux molecular-sieve alcohol permselective membrane and preparation method thereof

A molecular sieve, high-throughput technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of reducing hydrophobic performance, low molecular sieve membrane flux, thick molecular sieve membrane thickness, etc., and achieve good hydrophobic performance. , high separation factor, the effect of reducing mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of Example 1 Porous YSZ Hollow Fiber Support

[0033] Add polyvinylpyrrolidone into N-methyl-2-pyrrolidone, dissolve and then add polyethersulfone, stir until fully dissolved, then add yttrium-stabilized zirconia powder (commercially available, containing 3-8% mol of yttrium oxide) in batches ); the mass ratio of yttrium-stabilized zirconia to polyethersulfone, N-methyl-2-pyrrolidone and polyvinylpyrrolidone is 10:1:4.87:0.08. After the raw materials are fully stirred, they are moved into a stainless steel storage tank, and then extruded into a hollow fiber shape. After drying at room temperature, they are sintered at 1200-1600°C to form a YSZ hollow fiber support body.

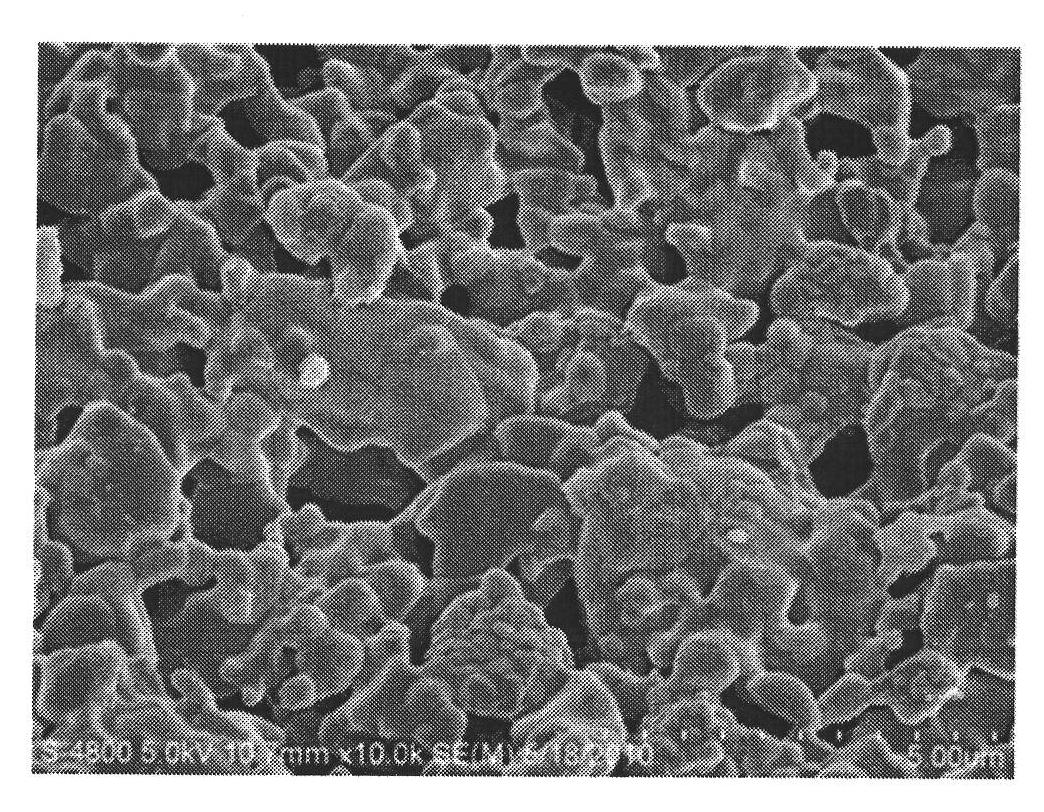

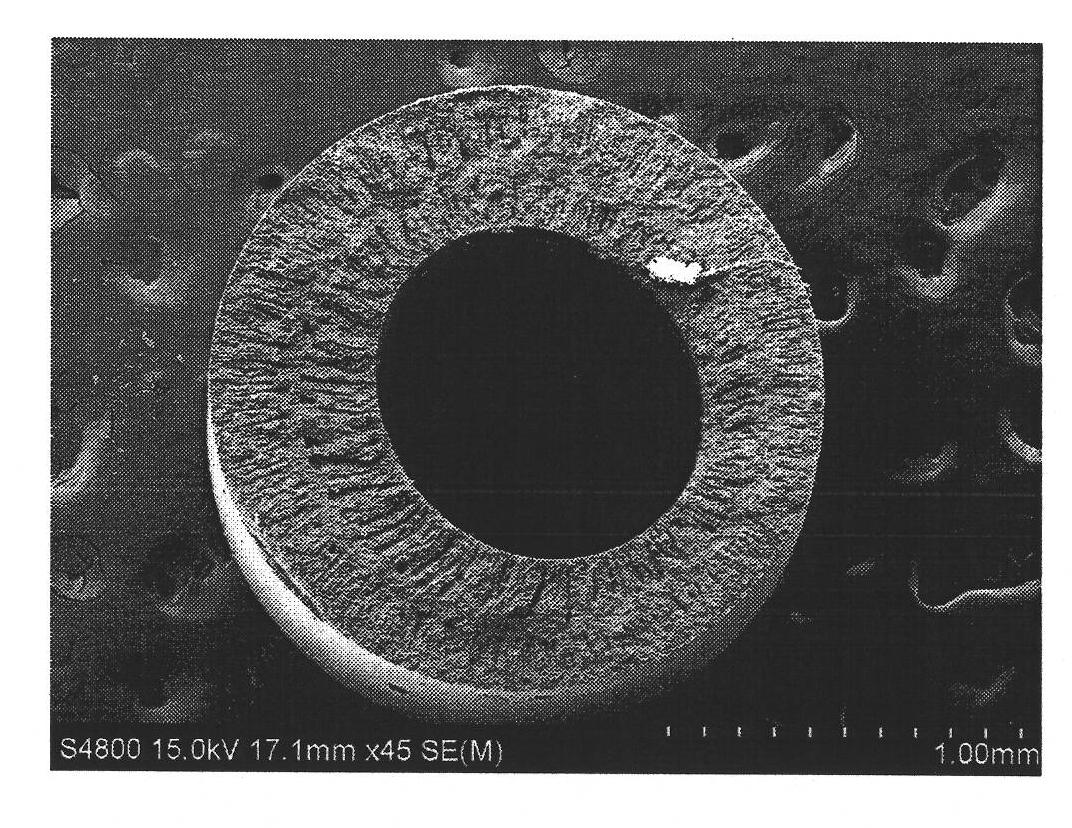

[0034]The pore size and porosity of the YSZ hollow fiber support are shown in Table 1: as the sintering temperature increases, the average pore size decreases gradually and the porosity decreases. figure 1 It is the surface electron micrograph of the YSZ hollow fiber support sintered at 1...

Embodiment 2

[0037] Example 2 Synthesis of Silicalite-1 molecular sieve membrane with YSZ hollow fiber as support body

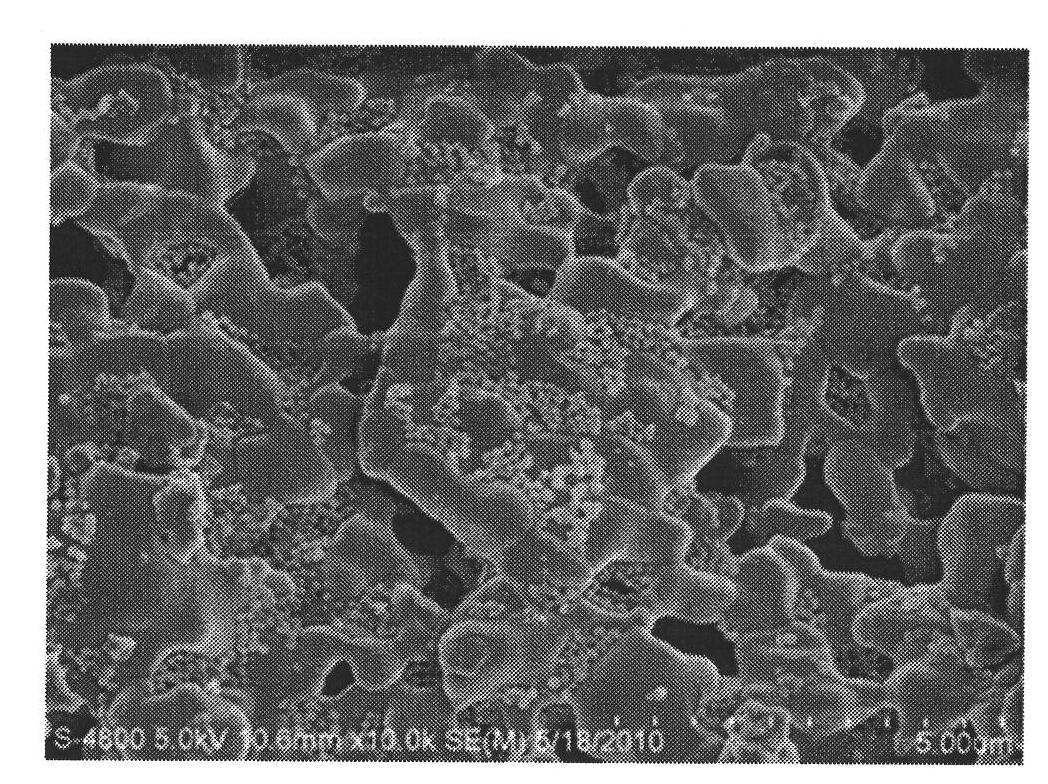

[0038] Self-made nano-scale Silicalite-1 molecular sieve particles were used as seed crystals, the seed crystal suspension was diluted with hydroxypropyl cellulose (HPC) and deionized water, and then the pH was adjusted to 3-4. The YSZ hollow fiber with an average pore size of 0.67 μm and a porosity of 56% was selected as a support, immersed in the seed crystal suspension for 3-5 seconds, dried and calcined at 450°C. From electron micrographs ( image 3 ) It can be seen that the surface of the support is evenly coated with Silicalite-1 molecular sieve seeds.

[0039] Take 5.66ml of tetrapropylammonium hydroxide with a concentration of 1M, 4ml of analytically pure tetraethyl orthosilicate and 52.5ml of deionized water and mix evenly (that is, the molar ratio of the three is 1:3.2:560) to prepare the secondary growth mother solution ; Place the seed crystal-coated suppor...

Embodiment 3

[0041] Example 3 Synthesis of Silicalite-1 molecular sieve membrane with YSZ hollow fiber as support body

[0042] The molar ratio of tetrapropylammonium hydroxide, tetraethylorthosilicate and water is controlled to be 1:4:692, and the hydrothermal synthesis is carried out at 180° C. for 24 hours. All the other conditions are the same as in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com