Method for preparing fluorine-containing mordenite zeolite membrane

A technology of mordenite and molecular sieve, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems that there are no literature reports on mordenite molecular sieve membranes, achieve good permeability, broad application prospects, and simple synthesis devices Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

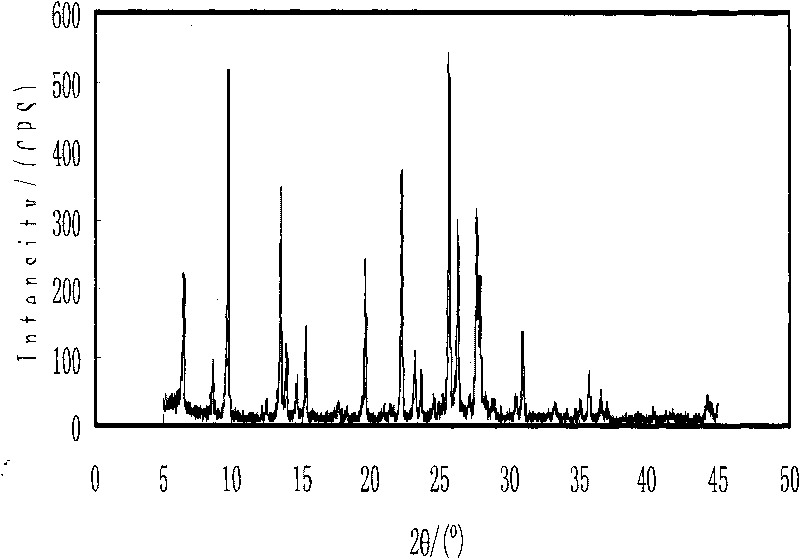

[0045] The preparation of embodiment 1 mordenite molecular sieve

[0046] SiO powder, sodium metaaluminate, sodium hydroxide, ammonium fluoride and deionized water are used as raw materials to prepare raw material solution SiO 2 -Al 2 o 3 -NaOH-NH 4 F-H 2 O system, the molar ratio of each component is:

[0047] SiO 2 / Al 2 o 3 =20,H 2 O / SiO 2 =15,

[0048] Na 2 O / SiO 2 =0.15, NH 4 F / SiO 2 =0.4

[0049] The prepared raw material solution was aged at room temperature for 12 hours, put into a stainless steel reaction kettle lined with polytetrafluoroethylene, and put the stainless steel reaction kettle into an oven at 180°C for 24 hours to synthesize. The synthesized crystals were washed with deionized water until neutral and then dried at 105° C. for 12 h. The synthesized powder was characterized by XRD, such as figure 1 As shown, it is consistent with the standard spectrum of MOR molecular sieve, and it is pure mordenite.

Embodiment 2

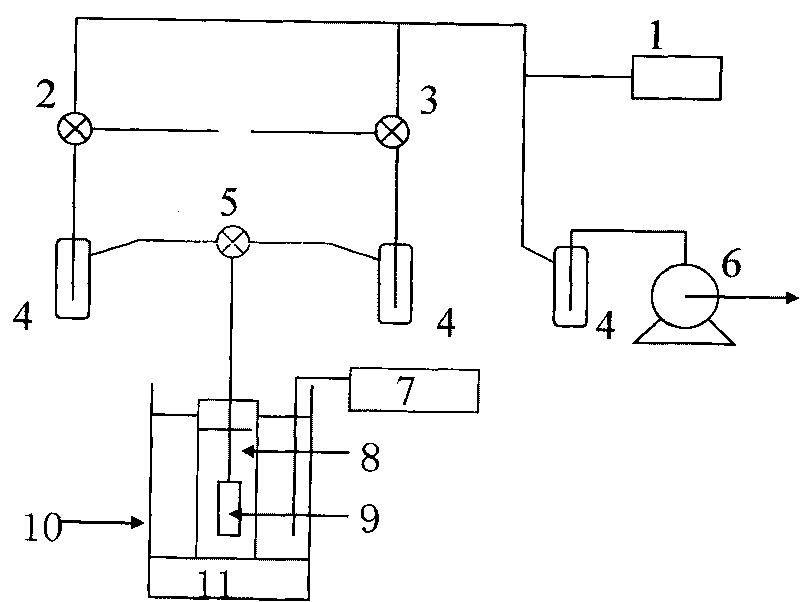

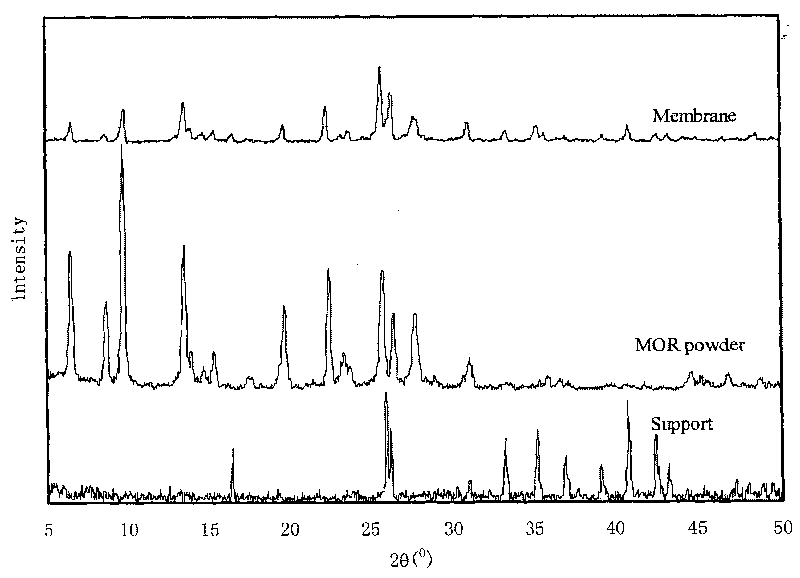

[0050] Embodiment 2 Preparation of fluorine-containing mordenite molecular sieve membrane

[0051] The support used in this experiment is tubular mullite produced by Nikkato Co., Ltd. in Japan (the composition of mullite is 67wt.%Al 2 o 3 and 33wt.% SiO 2 ) as a carrier for synthesizing mordenite membranes, the inner diameter and outer diameter of the carrier are 9mm and 12mm respectively, the length is 100mm, the porosity is about 43%, and the average pore diameter is about 1 μm. After pretreatment such as water ultrasonic cleaning and drying, a thin layer of mordenite molecular sieve powder is coated on the surface of the support body, and the loading density of the seed crystal is 0.5-2mg / cm 2 , and the seeded supports were dried at 30 °C for 1 hour before use.

[0052] Take aluminum hydroxide as the aluminum source, silica sol as the silicon source, sodium fluoride as the fluorine source and sodium hydroxide as the alkali source, mix with a certain amount of deionized w...

Embodiment 3

[0060] Embodiment 3 Preparation of fluorine-containing mordenite molecular sieve membrane

[0061] The raw material and operation of the synthetic liquid used are the same as in Example 2, only the time is shortened to 12h. The synthesized molecular sieve membranes were used for pervaporation experiments and characterizations, and the results of the pervaporation experiments are shown in M-3 and M-4 in Table 2.

[0062] Table 2 Pervaporation performance of fluorine-containing mordenite molecular sieve membranes on mullite carrier in water / ethanol system (75°C)

[0063]

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Tube outer diameter | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com