Composite fiber membrane with chiral molecular imprint and its prepn and application

A chiral molecule and fiber composite technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as poor sharing, difficult continuous operation, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

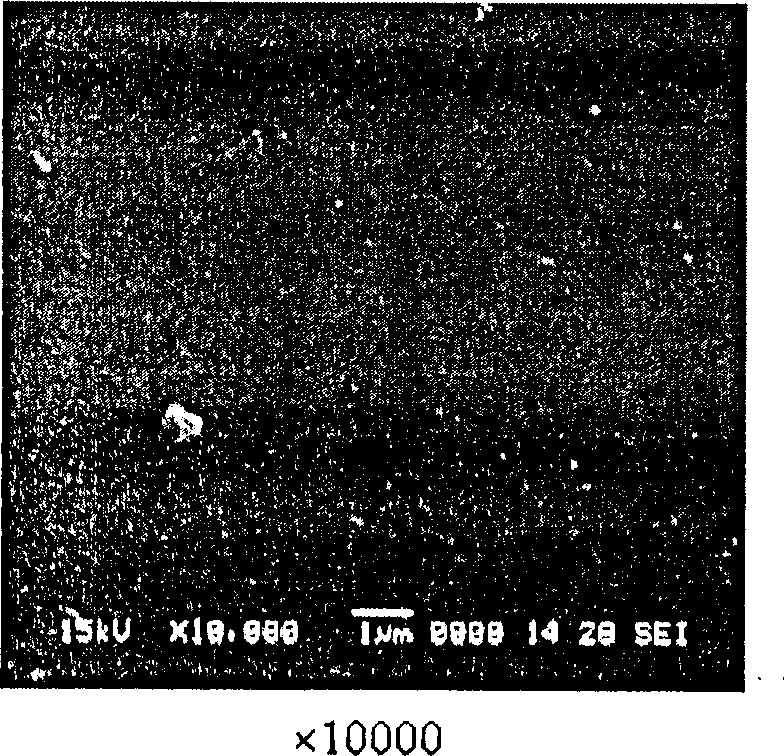

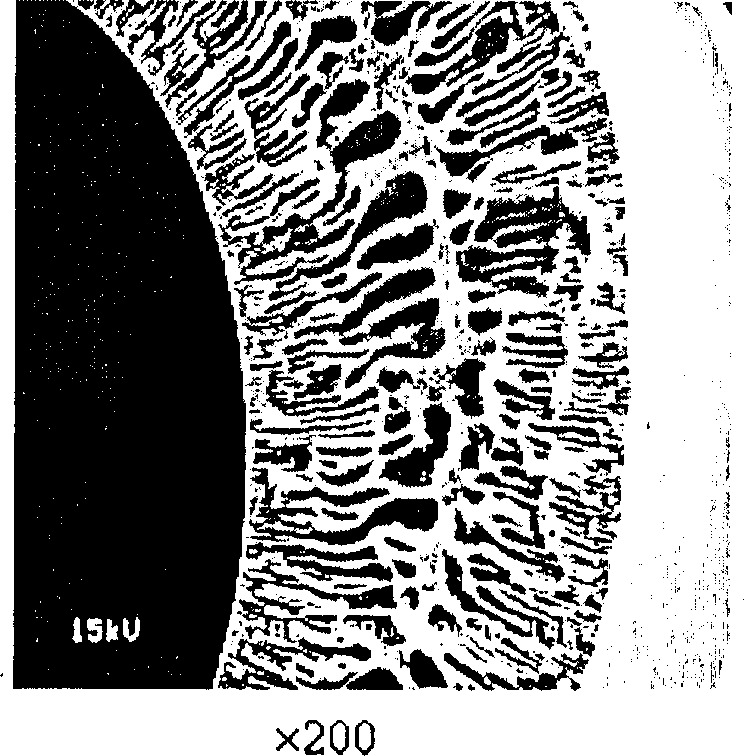

[0050] First, weigh raw materials according to mass percentage, azobisisobutyronitrile: 6%, acetonitrile: 94%, and prepare an initiator solution. The process is: add AIBN to acetonitrile and shake gently to dissolve AIBN. Then apply the solution evenly on the outer surface of the pre-prepared PSF hollow fiber, and let it dry.

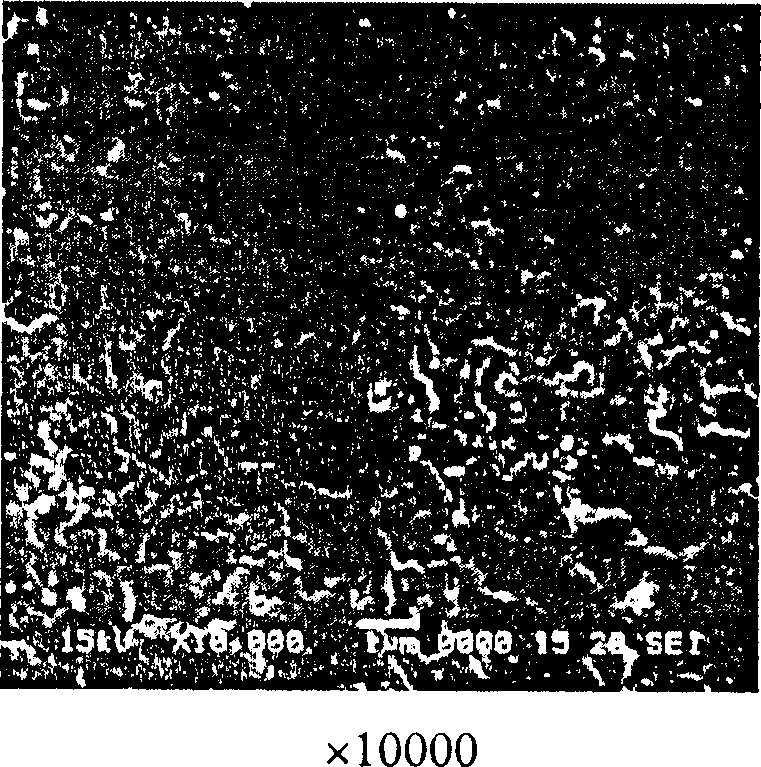

[0051] Then weigh raw materials by mass percentage, chiral compound dibenzoyl-L-tartaric acid: 2%; Acetonitrile: 60%; Methyl methacrylate: 5%; Ethylene glycol dimethacrylate: 32% to prepare Coating solution, the process is: first add L-DBTA to acetonitrile, shake it gently to dissolve it, let it stand for 2 hours at a temperature of 25°C, then add methyl methacrylate and ethylene glycol dimethacrylate, shake it Evenly, it is the coating solution. Then apply the coating solution evenly on the outer surface of the PSF hollow fiber membrane coated with the initiator, and after standing for 3 hours, place the PSF hollow fiber membrane in a vacuum drying oven...

Embodiment 2

[0056] According to the preparation conditions and process described in Example 1, the material is a hollow fiber ultrafiltration membrane of polyethersulfone (PES) as a support, and the others are the same as in Example 1. Repeat the process of Example 1 to obtain chiral The molecularly imprinted composite membrane is assembled into a membrane module, and the separation factor of the racemic L, D-DBTA solution can reach 2.0.

Embodiment 3

[0058] According to the preparation conditions and process described in Example 1, levofloxacin is used as the template molecule, and the others are the same as in Example 1, and the process of Example 1 is repeated to prepare the levofloxacin chiral molecularly imprinted composite film, and assemble Membrane-forming components, the separation factor of the racemic ofloxacin solution can reach 1.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Pure water flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com