Production process for composite material of swimming pool

A composite material and production process technology, applied in the direction of synthetic resin layered products, layered products, lamination, etc., can solve the problems of composite material lamination strength damage, easy fading, short service life, etc., to achieve scientific and reasonable production process , Good hand feeling and resilience, low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

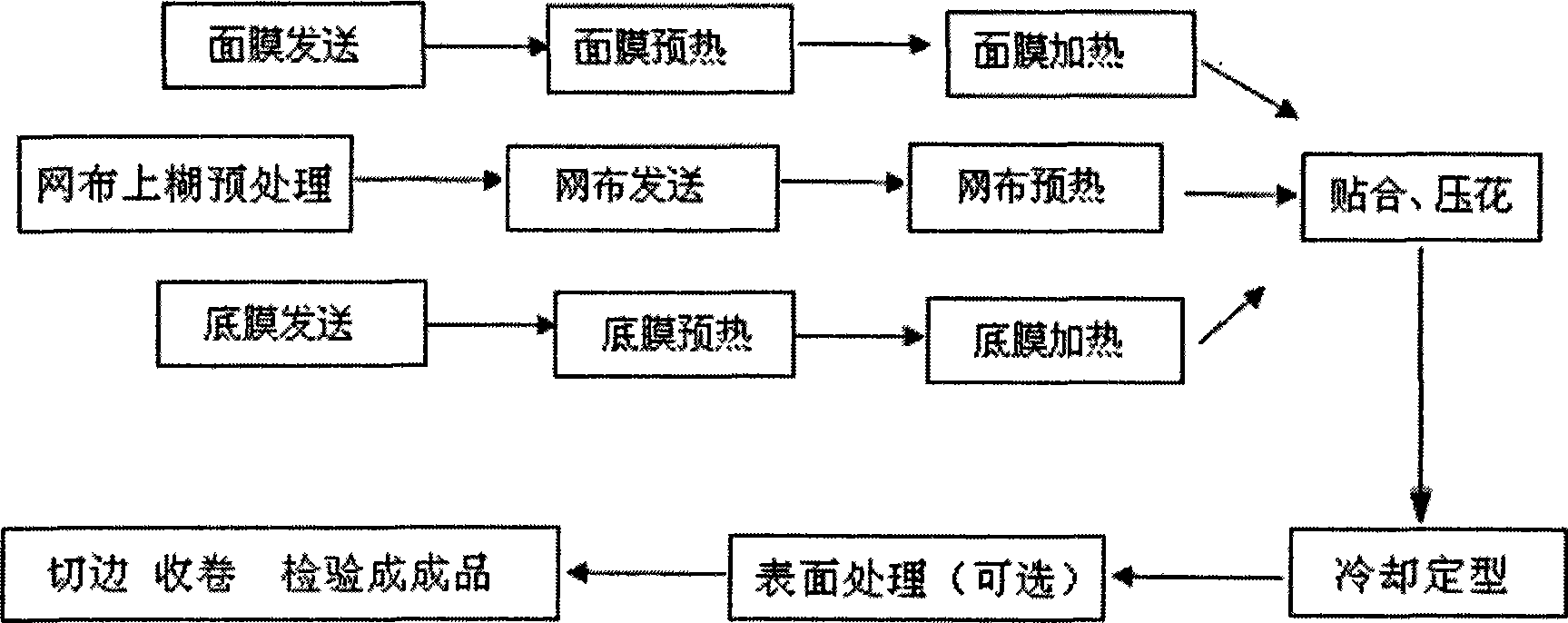

[0021] The specific steps of the production process are:

[0022] (1) Paste pretreatment on the mesh: Use a coating machine to resist wicking type high elongation, low shrinkage, non-absorbent polyester mesh for dipping and coating treatment of PVC paste, anti-wicking mesh can prevent swimming pool compounding When the material holds a large amount of water, due to the static pressure of the water, the wicking phenomenon of the mesh fiber causes water seepage; the advantage of using PVC paste dip coating treatment is the bonding fastness of the swimming pool composite material and avoiding the use of traditional PU Defects in which the adhesive undergoes hydrolytic degradation. The raw material formula of PVC paste adhesive: EPVC 100PHR, K=61 of the EPVC, DOP 80PHR, low toxicity barium zinc stabilizer 2PHR, antifungal agent 0.5PHR, VP adhesion promoter 4PHR, anti-UV additive 0.5PHR And according to the needs of the production process, add an appropriate viscosity reducer. Gen...

Embodiment 2

[0034] The specific steps of the production process are:

[0035] (1) Paste pretreatment on the mesh: Use a coating machine to resist wicking type high elongation, low shrinkage, non-absorbent polyester mesh for dipping and coating treatment of PVC paste, anti-wicking mesh can prevent swimming pool compounding When the material holds a large amount of water, due to the static pressure of the water, the wicking phenomenon of the mesh fiber causes water seepage; the advantage of using PVC paste dip coating treatment is the bonding fastness of the swimming pool composite material and avoiding the use of traditional PU Defects in which the adhesive undergoes hydrolytic degradation. The raw material formula of PVC paste adhesive: EPVC 100, K=61 of said EPVC, DOP 110PHR, low toxicity barium zinc stabilizer 5PHR, antifungal agent 0.5PHR, VP adhesion promoter 6PHR, anti-UV additive 0.5PHR And add an appropriate viscosity reducer according to the needs of the production process. Gener...

Embodiment 3

[0047] The specific steps of the production process are:

[0048] (1) Paste pretreatment on the mesh: Use a coating machine to resist wicking type high elongation, low shrinkage, non-absorbent polyester mesh for dipping and coating treatment of PVC paste, anti-wicking mesh can prevent swimming pool compounding When the material holds a large amount of water, due to the static pressure of the water, the wicking phenomenon of the mesh fiber causes water seepage; the advantage of using PVC paste dip coating treatment is the bonding fastness of the swimming pool composite material and avoiding the use of traditional PU Defects in which the adhesive undergoes hydrolytic degradation. The raw material formula of PVC paste adhesive: EPVC 100, K=61 of said EPVC, DOP100PHR, low toxicity barium zinc stabilizer 4PHR, antifungal agent 0.5PHR, VP adhesion promoter 5PHR, anti-UV additive 0.5PHR and According to the needs of the production process, add an appropriate viscosity reducer. Gener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com