Production technology of composite material for yacht

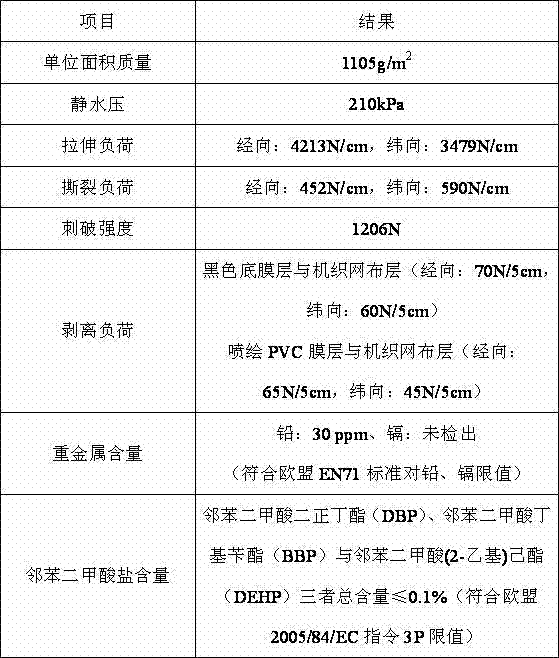

A production process and composite material technology, applied in the direction of synthetic resin layered products, layered products, lamination, etc., can solve the problems of easy aging, scratches, pattern defects, etc., to achieve high market competitiveness, good waterproof performance, High peel load effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A production process of a composite material for a yacht, the steps of which are:

[0069] (1) The transparent elastic PVC mask layer 1, the spray-painted PVC film layer 2, and the black base film layer 4 are respectively prepared through the following procedures:

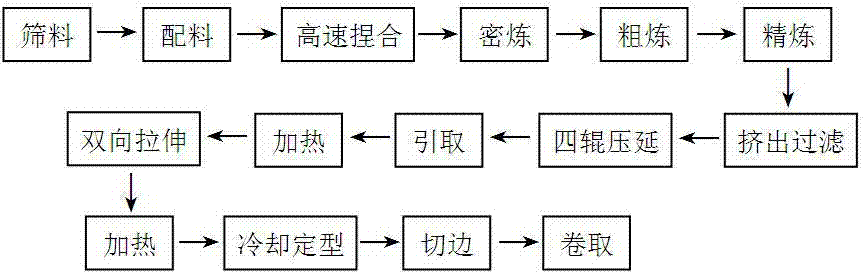

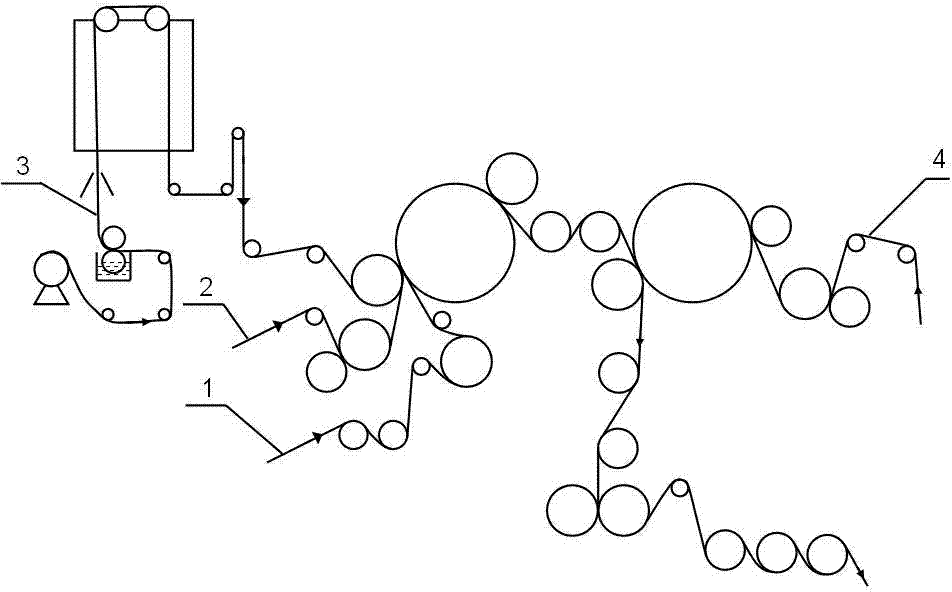

[0070] Screening → batching → high-speed kneading at 195°C → banburying at 200°C → rough refining at 195°C → refining at 205°C → extrusion and filtration at 180°C → four-roll calendering, 1#180°C, 2#185°C, 3#170°C, 4 #163°C → 160°C extraction → 180°C heating → biaxial stretching → 150°C heating → cooling and shaping → trimming → coiling; Among them, the spray-painted PVC film layer 2 can be photo-painted with various exquisite patterns according to needs.

[0071] The raw material of transparent elastic PVC mask layer 1 is composed of: 100 parts by weight of PVC resin powder with degree of polymerization K=80, 5 parts of thermoplastic polyurethane, 40 parts of citric acid ester plasticizer, auxiliary plastic...

Embodiment 2

[0087] A production process of a composite material for a yacht, the steps of which are:

[0088] (1) The transparent elastic PVC mask layer 1, the spray-painted PVC film layer 2, and the black base film layer 4 are respectively prepared through the following procedures:

[0089] Screening → batching → high-speed kneading at 200°C → internal mixing at 205°C → rough refining at 195°C → refining at 205°C → extrusion and filtration at 185°C → four-roll calendering, 1#185°C, 2#190°C, 3#175°C, 4 #165°C→162°C Extraction→185°C Heating→Biaxial Stretching→155°C Heating→Cooling and Shaping→Edging Trimming→Coiling; Among them, the spray-painted PVC film layer 2 can be photo-painted with various exquisite patterns according to needs.

[0090] The raw material of transparent elastic PVC mask layer 1 is composed of: 100 parts by weight of PVC resin powder with degree of polymerization K=80, 8 parts of thermoplastic polyurethane, 55 parts of citrate plasticizer, auxiliary plasticizer epoxy r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com