Method for producing base oil of lubricating oil by using Fischer-Tropsch synthesis wax

A technology of lubricating oil base oil and Fischer-Tropsch synthetic wax, which is applied in the directions of lubricating composition, petroleum industry, processing hydrocarbon oil, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This example takes a kind of Fischer-Tropsch synthetic wax as raw material, and its properties are shown in Table 1.

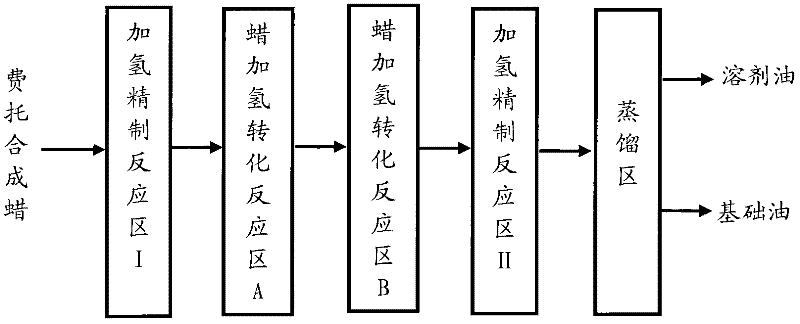

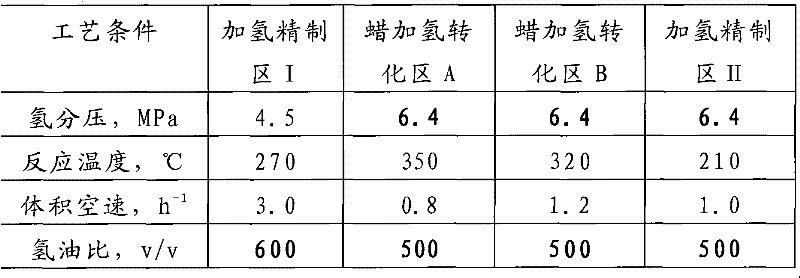

[0039] according to figure 1 The process flow processes the raw material. The catalysts are as follows: Catalyst a is used in hydrorefining zone I, catalyst b is used in both wax hydroconversion reaction zone A and wax hydroconversion reaction zone, the catalyst loading ratio of A zone and B zone is 3:2, and the hydrorefining zone Catalyst c is used in Zone II, and the operating conditions are shown in Table 2.

[0040] See Table 3 for the material balance after separation in the distillation zone.

[0041] The properties of lubricating oil base oil are shown in Table 4.

[0042] Table 1

[0043]

[0044] Item F-T synthetic wax

[0045]

[0046] Density(20℃) / g.·cm -3 0.8055

[0047] Freezing point / ℃ 95 (melting point)

[0048] Sulfur conte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com