Method for reproducing tobacco leaves by paper-making method through bamboo pulp fibers instead of wood pulp fibers

A technology of bamboo pulp fiber and reconstituted tobacco leaves, which is applied in the fields of application, tobacco, and tobacco preparation. It can solve the problems of no public reports, etc., and achieve the effect of simple method and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

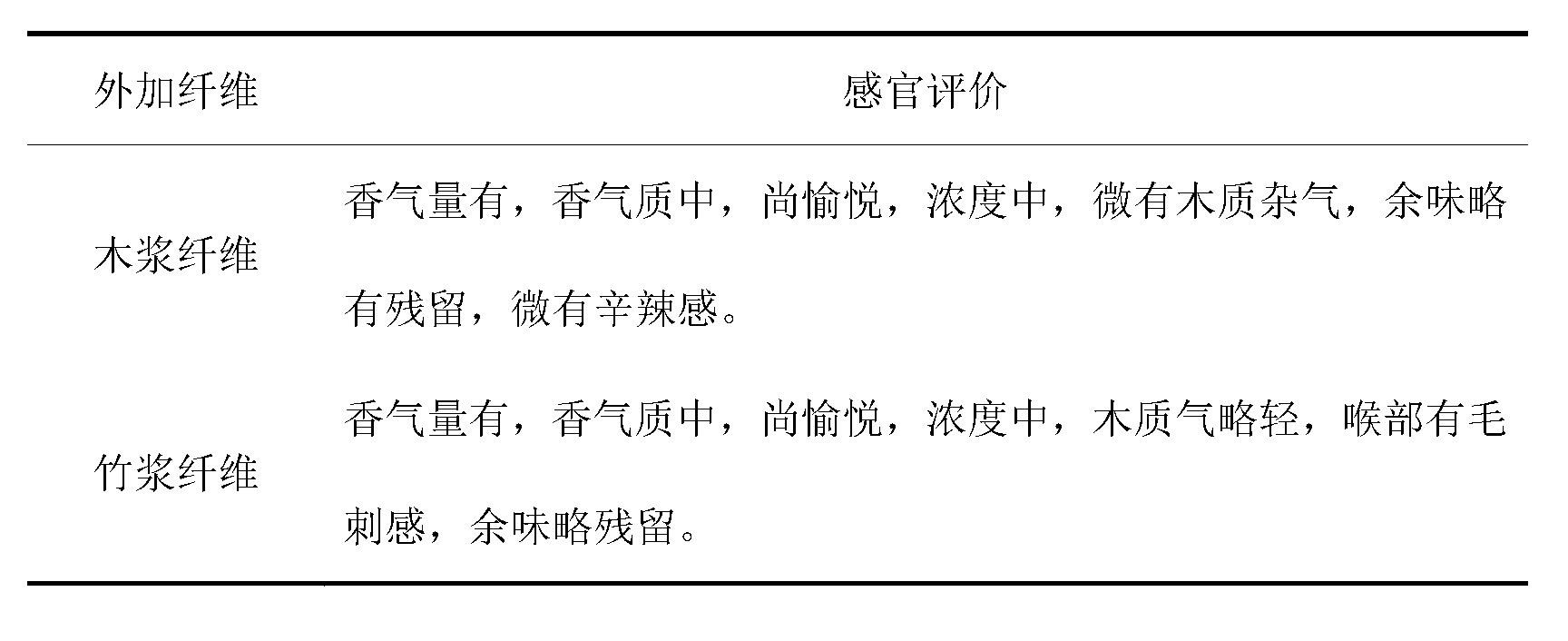

Image

Examples

Embodiment Construction

[0019] Concrete steps of the present invention are as follows:

[0020] a. Preparation of bamboo pulp fiber

[0021] Cut the air-dried Dalong bamboo into slices, cook in a cooking pot at a temperature of 165°C, heat up for 120 minutes, and keep warm for 60 minutes to make bamboo pulp, then temperature 90°C, time 60 minutes, oxygen pressure 0.6 Mpa, MgSO 4 The dosage is 0.5%, the NaOH dosage is 2.5%, and the pulp concentration is 10% to carry out oxygen deoxidation treatment to obtain oxygen deoxidized bamboo pulp;

[0022] b. Preparation of coating solution

[0023] Re-roasted tobacco stems, chips and tobacco powder are used as raw materials, wherein the tobacco stems are extracted with water alone for 60 minutes, and the chips and tobacco powder are mixed at a ratio of 70:30 and extracted with water for 60 minutes. After the raw materials are extracted, the solid-liquid separation is carried out separately, and the liquid is concentrated in a rotary evaporator at a temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com