Thermal treatment method of tantalum powder

A heat treatment method and vacuum heat treatment technology, applied in the field of tantalum powder production, can solve the problems of low porosity, high oxygen content of tantalum powder, uncontrollable intense oxidation, etc., and achieve the effects of low leakage current, low oxygen content and high specific volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

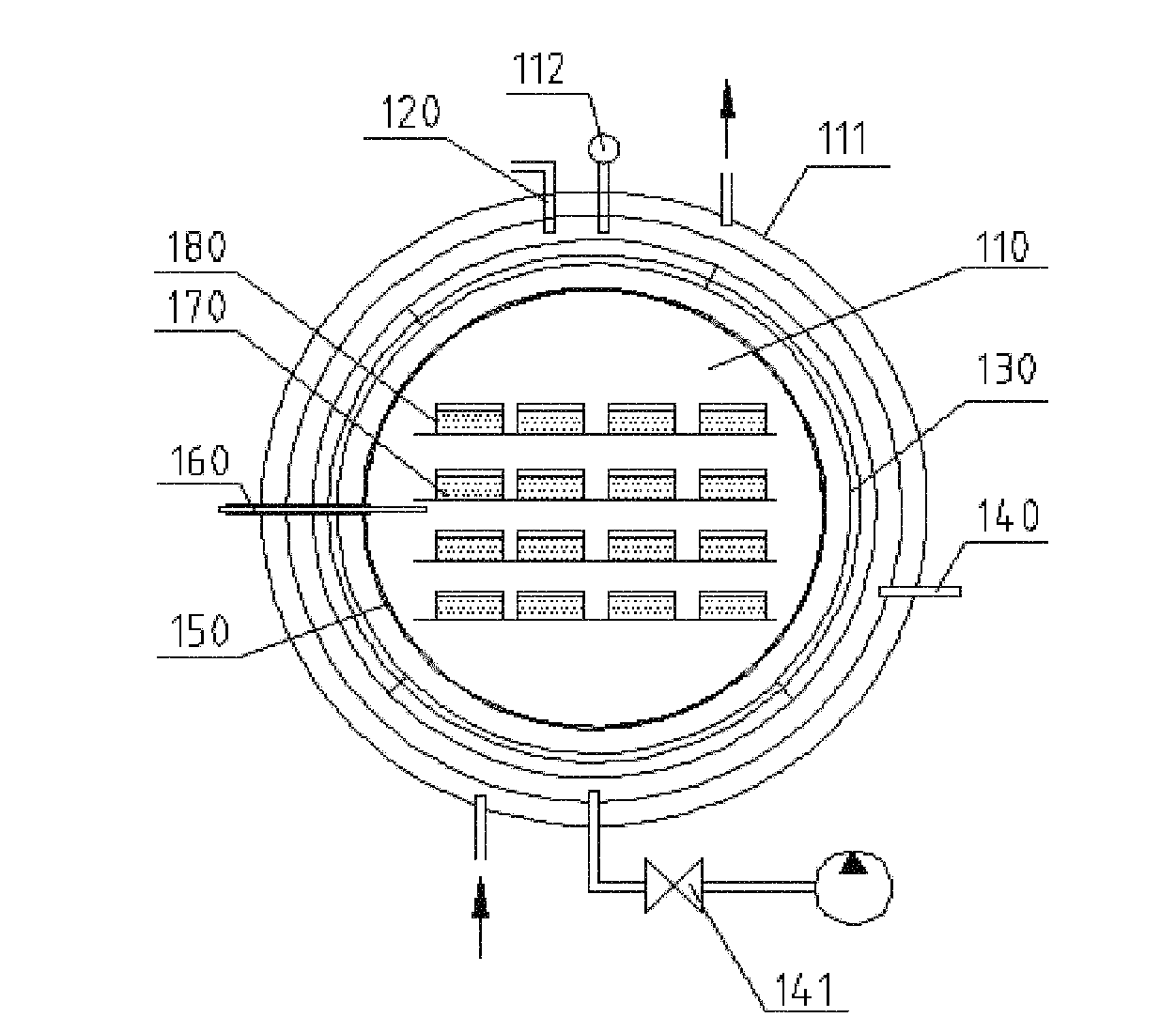

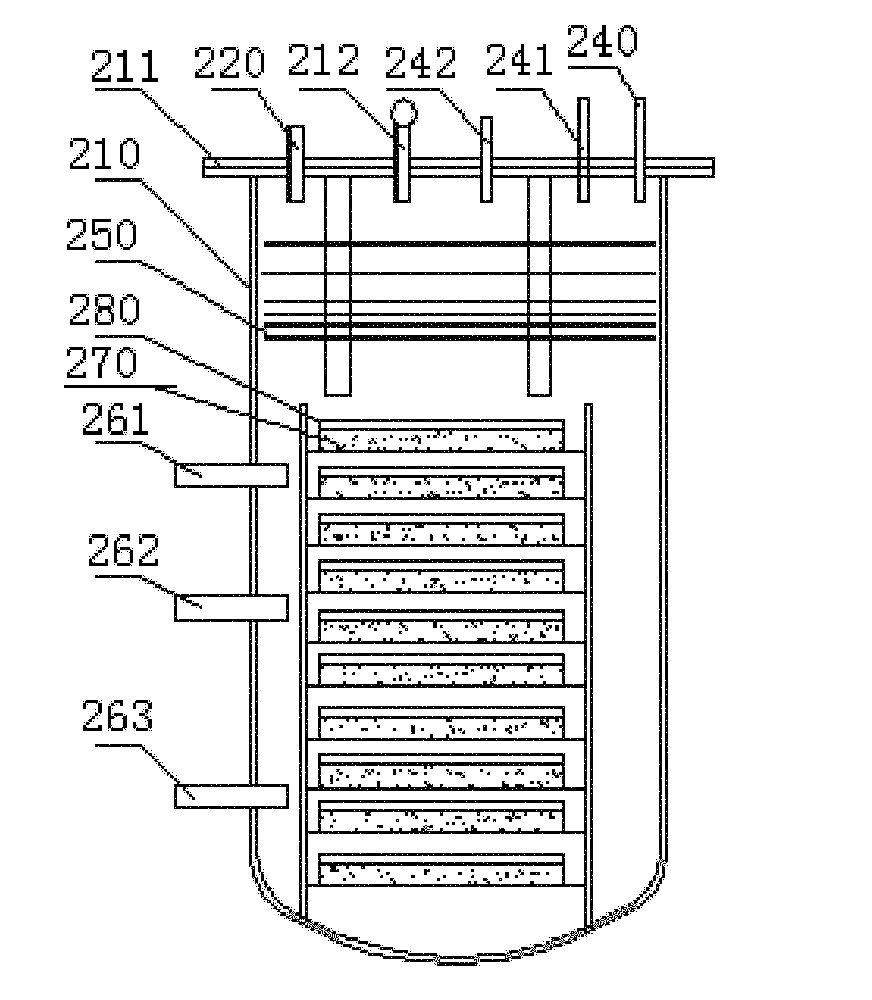

Method used

Image

Examples

Embodiment

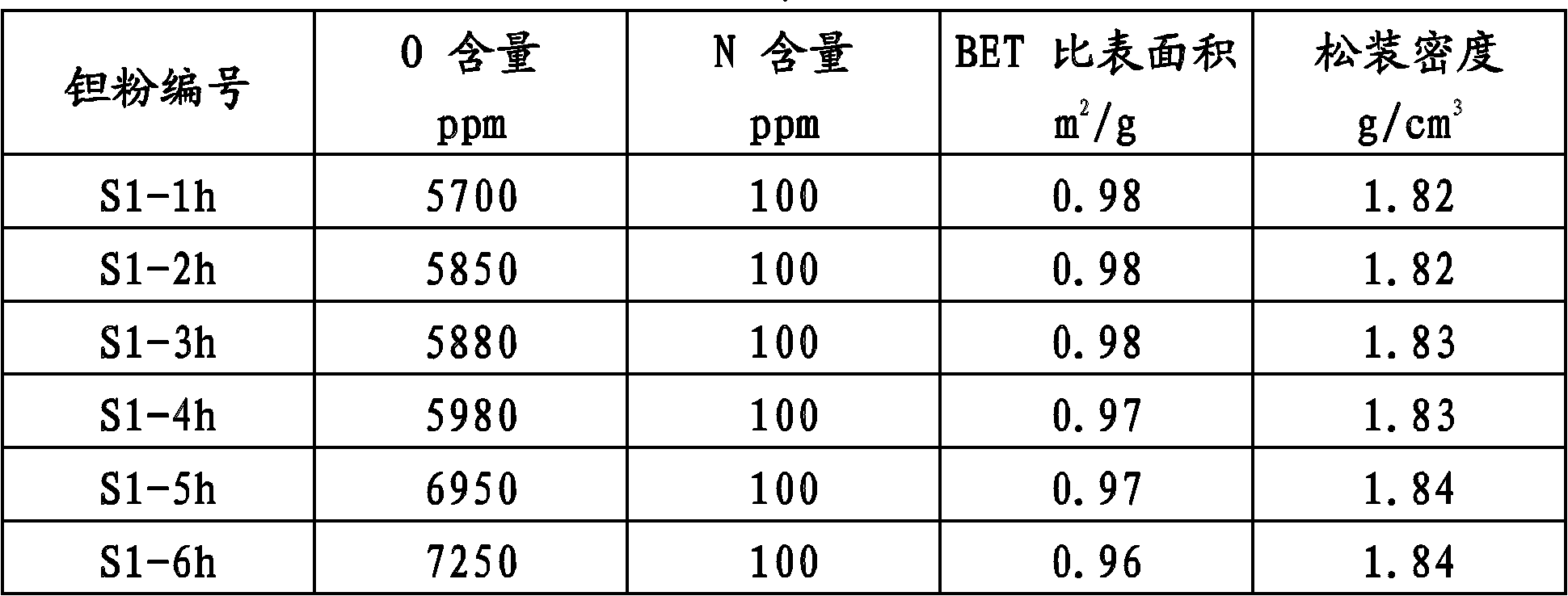

[0047] Embodiment 1-1, Embodiment 1-2, Embodiment 1-3, Embodiment 1-4, Embodiment 1-5 and Embodiment 1-6, experiment on the thickness of tantalum powder charge in vacuum heat treatment stage

[0048] With a specific surface area of 1.6m 2 / g, bulk density is 0.57g / cm 3 , has a porosity of 96.56%, and its oxygen content is the original tantalum powder prepared by sodium reduction potassium fluorotantalate of 4800ppm, mixed with 80ppm of phosphorus by weight of the tantalum powder, spheroidized and granulated, and the bulk density obtained is 1.08g / cm 3 granulated tantalum powder. After the above-mentioned spheroidized and granulated tantalum powder was gently poured into a tantalum crucible of 350mm×210mm×75mm, the tantalum powder in the crucible had a porosity of 93.2% (96.52% of the porosity of the original tantalum powder). In embodiment 1-1, embodiment 1-2, embodiment 1-3, embodiment 1-4, embodiment 1-5 and embodiment 1-6, the thickness of tantalum powder in the cruci...

Embodiment 2-1、 Embodiment 2-2、 Embodiment 2-3、 Embodiment 2-4 and Embodiment 2-5

[0061] Example 2-1, Example 2-2, Example 2-3, Example 2-4 and Example 2-5, the influence of packing density / porosity of tantalum powder in vacuum heat treatment stage

[0062] Embodiment 2-1, embodiment 2-2, embodiment 2-3, embodiment 2-4 and embodiment 2-5 use the same raw material tantalum powder with a porosity of 96.56% as embodiment 1-1, carry out Spheroidizing and granulating to obtain a bulk density of 1.08g / cm 3 The granulated tantalum powder is packed into a vacuum heat treatment crucible so that the thickness of the tantalum powder is 51mm. Embodiment 2-1 is to pour tantalum powder into a vacuum heat treatment crucible gently, and its porosity is 93.49%, which is 96.8% of the original tantalum powder porosity; embodiment 2-2 is to pour tantalum powder into a vacuum heat treatment crucible , shake the crucible gently, the packing density of tantalum powder is 1.13g / cm 3 , the porosity is 93.19%, which is 96.51% of the porosity of the original tantalum powder; in emb...

Embodiment 3-1、 Embodiment 3-2

[0076] Embodiment 3-1, embodiment 3-2, embodiment 3-3 and embodiment 3-4, the impact of deoxidation heat treatment tantalum powder charging thickness on the performance of tantalum powder

[0077] With a specific surface area of 0.95m 2 / g, bulk density is 1.82g / cm 3 (with a porosity of 89.04%), the heat-treated sodium-reduced tantalum powder with an oxygen content of 5600ppm and a N content of 90ppm is mixed with 1.6% magnesium powder by weight of the tantalum powder to form a mixed powder, and the above mixed powder is loaded into a deoxidized In the heat treatment crucible, the charging thicknesses of the powders in Example 3-1, Example 3-2, Example 3-3 and Example 3-4 are respectively 35mm, 45mm, 55mm and 75mm, respectively having 87.9%, 88.3% , 88.8% and 88.5% porosity, respectively 98.7%, 99.2%, 99.7% and 99.4% of the original tantalum powder porosity. Carry out deoxidation heat treatment and follow-up treatment according to the condition of embodiment 1-1, obtain em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com