Patents

Literature

36results about How to "Realize continuous pouring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

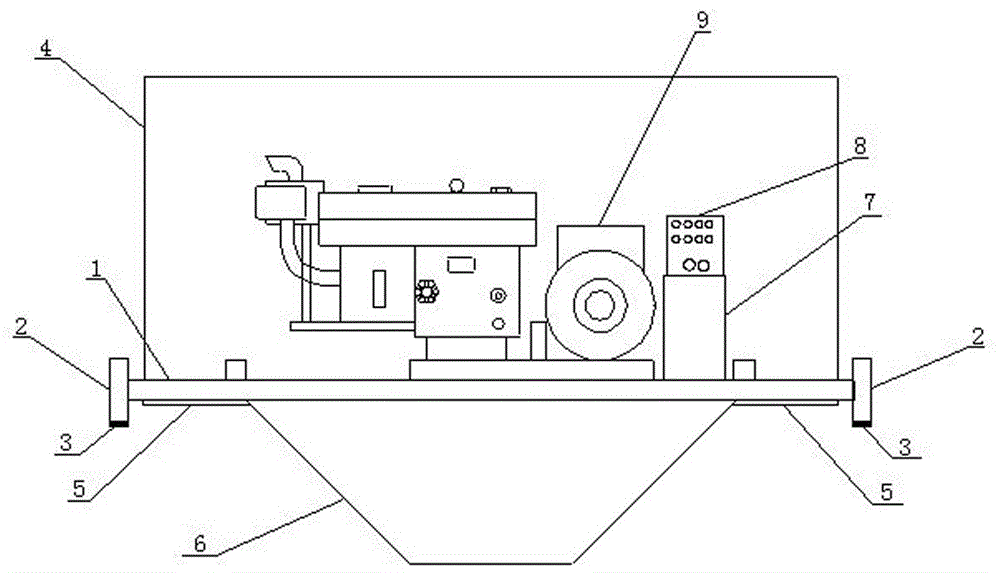

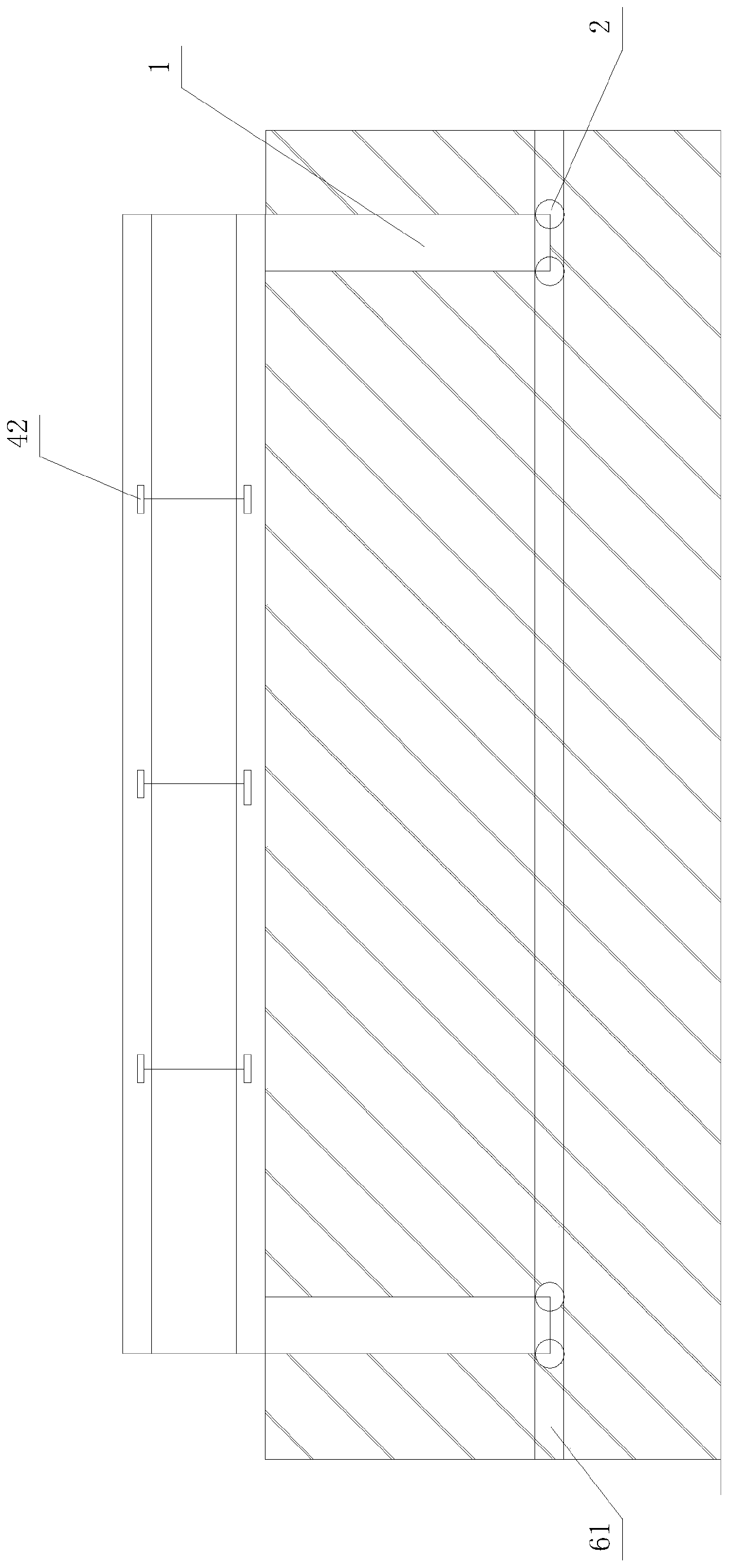

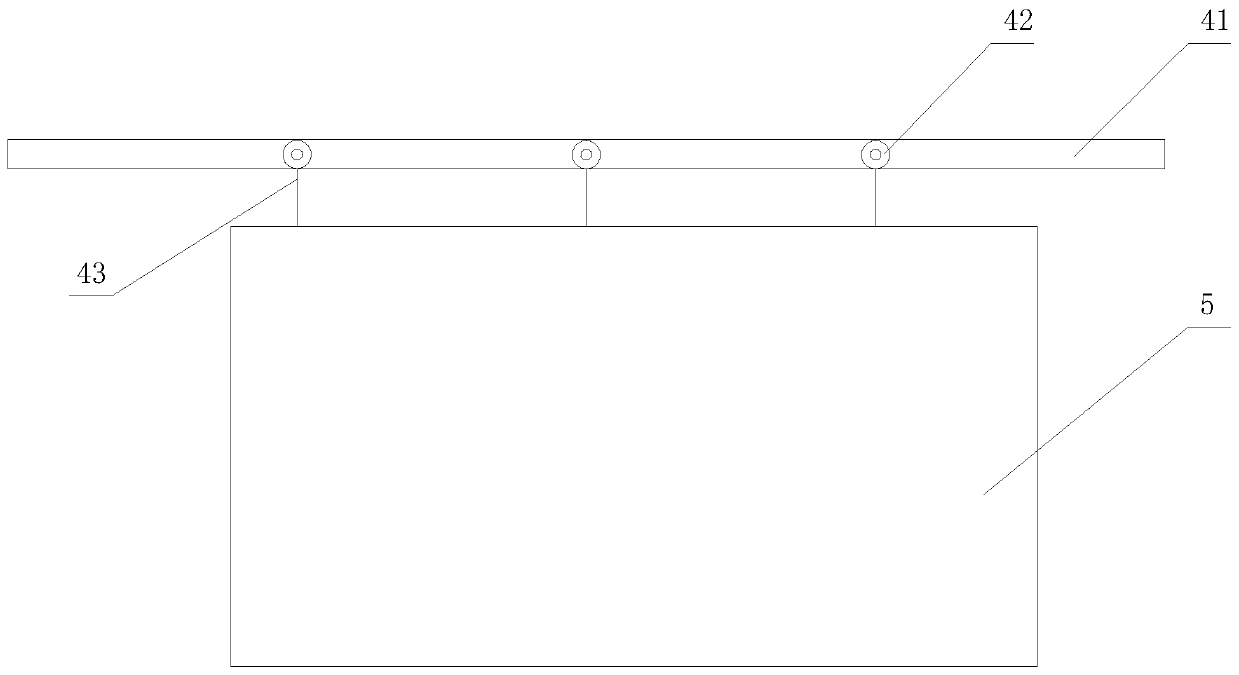

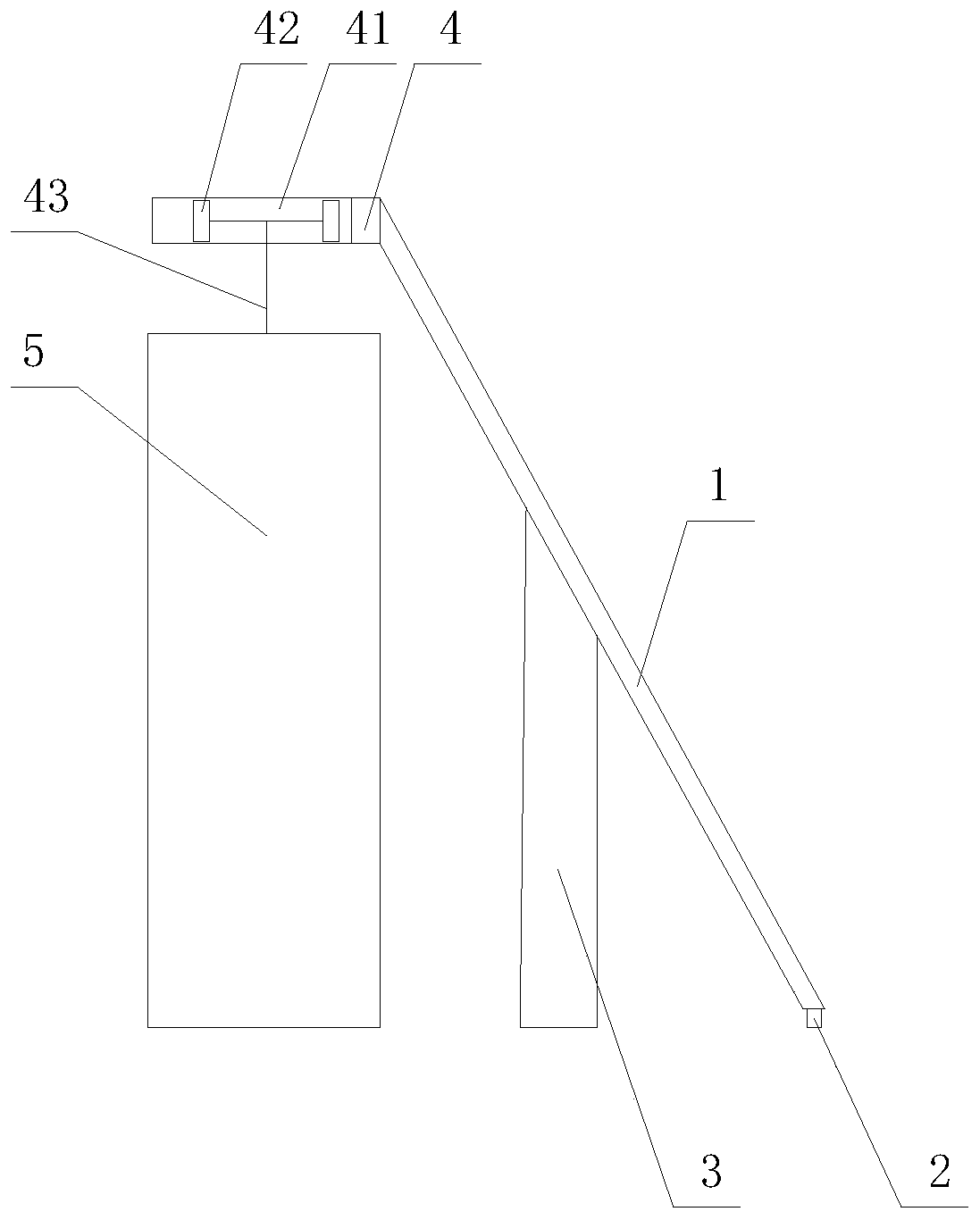

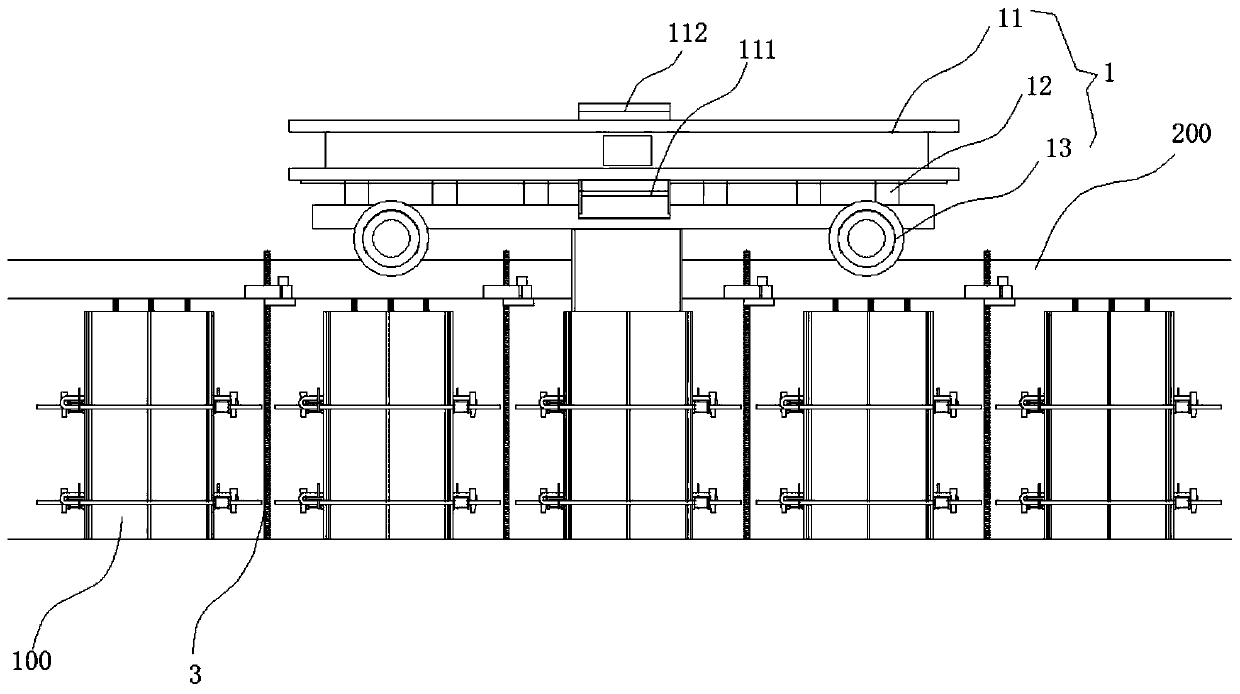

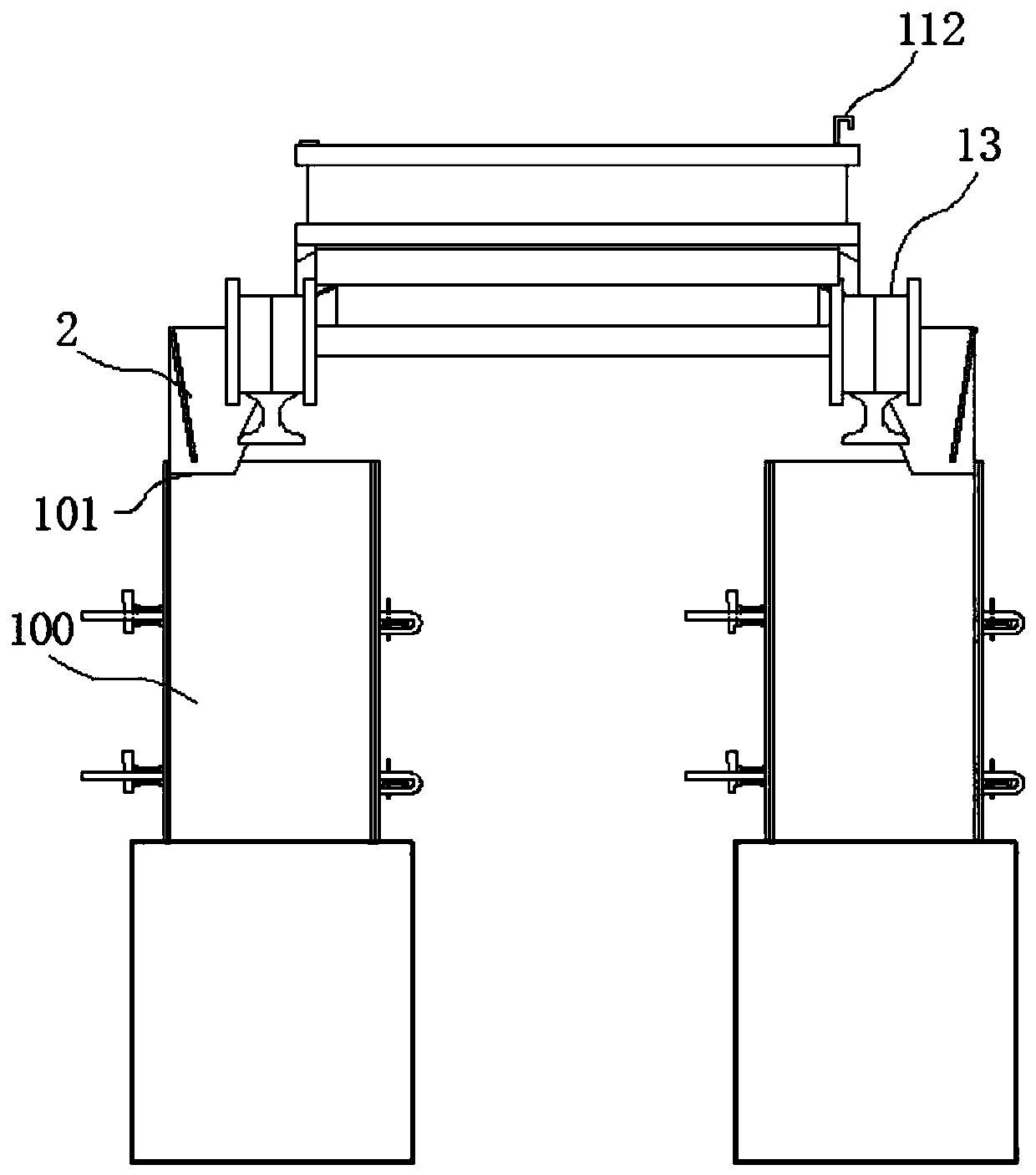

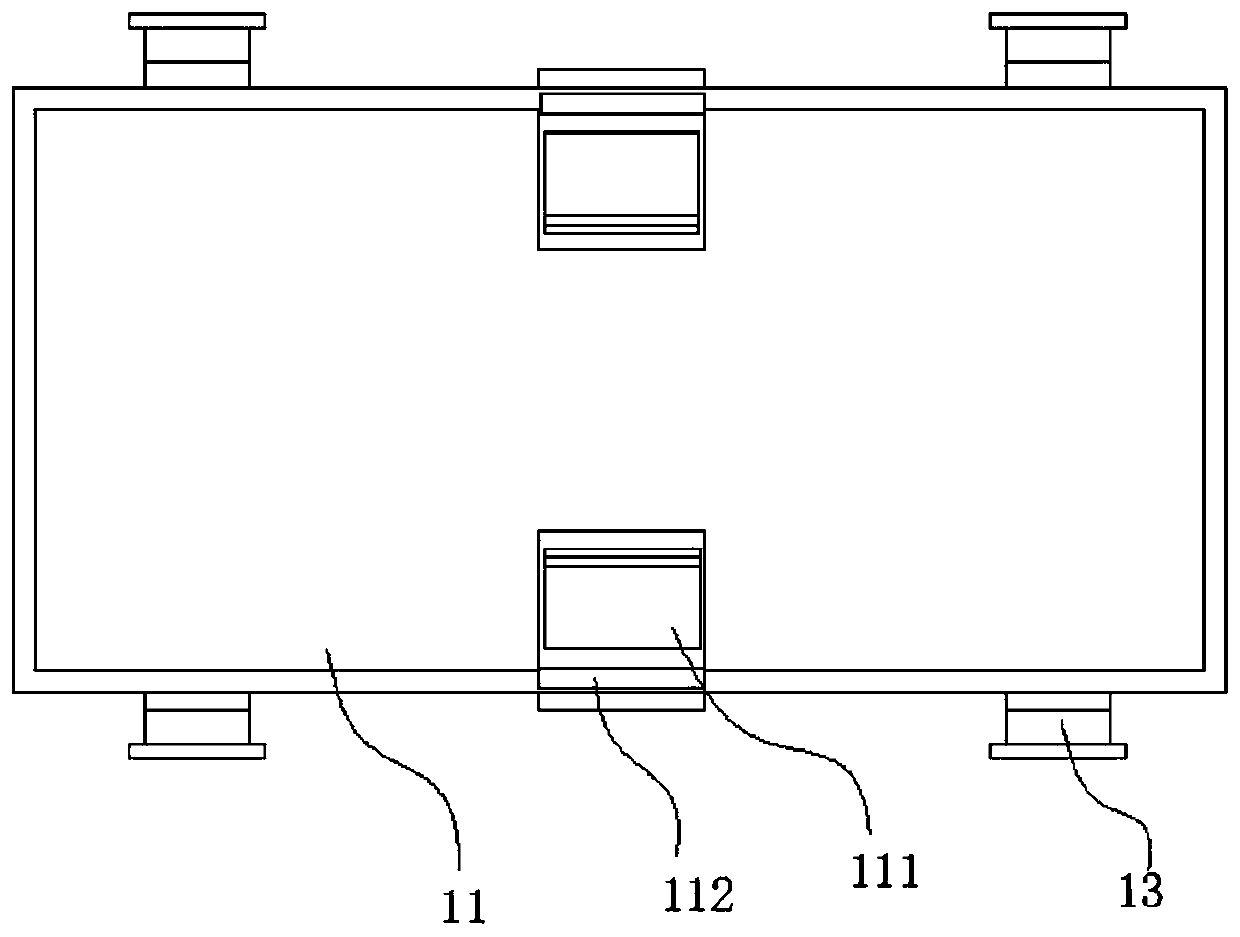

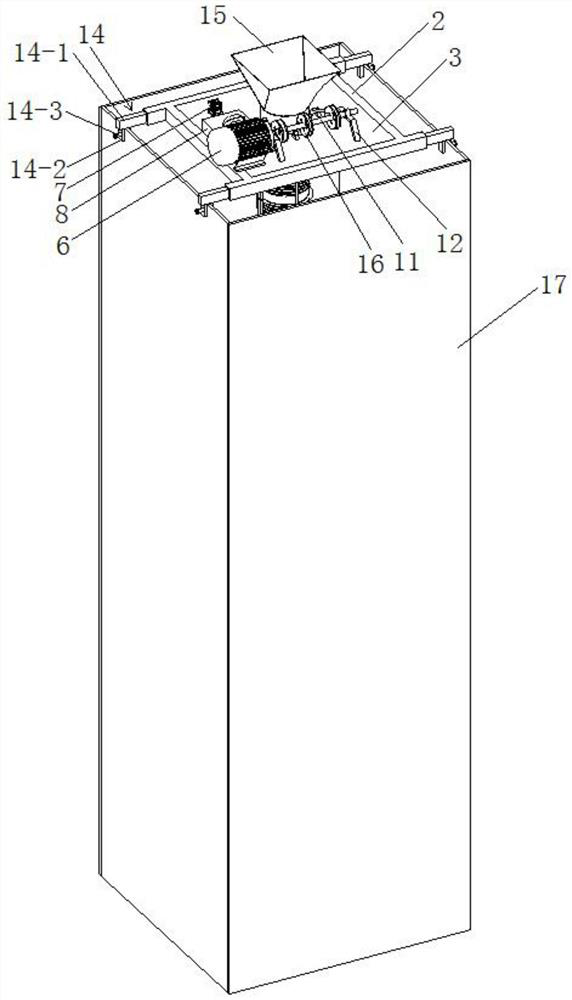

One-step forming and construction equipment and construction method for gutter

InactiveCN106758704AImprove construction efficiencyImprove construction qualityRoads maintainenceArchitectural engineeringMaterial distribution

The invention belongs to the technical field of gutter construction, and particularly discloses one-step forming and construction equipment and a construction method for a gutter. The construction equipment comprises walking tracks arranged on tops of slopes on two sides of the gutter side by side, idler wheels in rolling fit with the walking tracks, a limit platform supported among all the idler wheels, an electric generator, a vibrating table, a feed bin, a control console for controlling the vibrating table, and a setting steel mould fixed below the limit platform and matched with the gutter, wherein the electric generator, the vibrating table and the feed bin are fixed on the limit platform. According to the construction method, multiple procedures such as material distribution, spreading, vibrating and leveling can be completed in one step, man power is saved, and the spreading quality and efficiency are improved. Continuous concrete pouring of the gutter is realized, one-step forming is realized, concrete pouring of the gutter of a roadbed is completed in a high quality and high efficient way, and the integrality of a concrete structure is effectively ensured.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +1

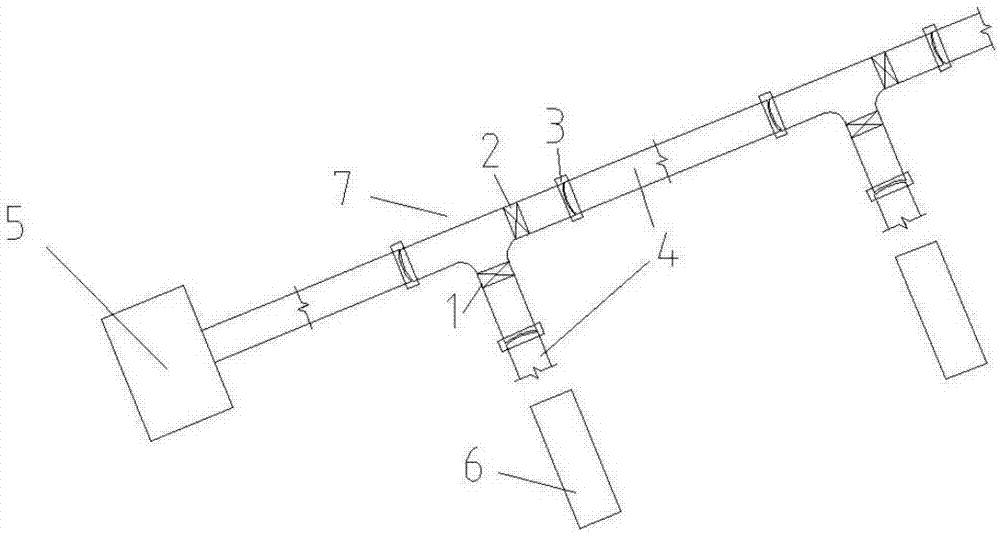

Method for constructing concrete structure of subway contact passage through ground pouring and freezing method

ActiveCN107740699AGuarantee unimpededEnsure that the pouring is denseUnderground chambersTunnel liningStructural engineeringClerestory

The invention discloses a method for constructing a concrete structure of a subway contact passage through a ground pouring and freezing method. The method for constructing the concrete structure of the subway contact passage comprises the following steps that (1) drilling is conducted from the ground above the contact passage toward the interior of the contact passage; (2) concrete sliding tubesare placed downwards in drilled drill holes in the step (1); (3) after a frozen wall meets the excavation condition of the contact passage, earth excavation of the contact passage is conducted in a subway tunnel, and protective treatment is conducted on the concrete sliding tubes after the concrete sliding tubes are dug out; and (4) the concrete structure of a bottom plate (5) of the contact passage is poured by utilizing the concrete sliding tube located in the center of the contact passage, and the side wall concrete structure and the arch crown concrete structure concrete structure are poured by utilizing the concrete sliding tubes located in the flare opening position. According to the method for constructing the concrete structure of the subway contact passage through the ground pouring and freezing method, compact pouring of concrete on an arch crown of the contact passage can be achieved, opening or holes in the concrete on the arch crown of the contact passage can be effectively prevented, it is effectively ensured that the thickness of the concrete structure of the contact passage meets the design requirement, and hidden dangers caused by the quality of the concrete structure of the contact passage are eliminated.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Production method of high-cleanliness high-titanium low-carbon steel

The invention relates to a production method of high-cleanliness high-titanium low-carbon steel, and belongs to the technical field of ferrous metallurgy. The invention aims to solve the technical problems of poor steel quality, low cleanliness and low quality of a finally produced product when the titanium content is high. The invention provides a production method of high-cleanliness high-titanium low-carbon steel, and the production method comprises the following steps of carrying out converter-RH-argon blowing-slab continuous casting process flow production, carrying out converter end point control, carrying out converter tapping and carrying out RH step-by-step deoxidation alloying on molten steel; and high-titanium low-carbon steel refining slag is added into a steel ladle for slagging in the converter tapping process, the components of the steel ladle slag are controlled, casting powder is adopted in the pouring process, and the titanium content in the steel is 0.15%-0.8% by mass. According to the production method, smooth pouring of the high-titanium low-carbon steel can be achieved, auxiliary materials such as the steel ladle slag, a tundish covering agent and the castingpowder have the good capacity of absorbing nonmetallic inclusions, the performance can still be kept stable after a large number of inclusions are absorbed, the cleanliness of molten steel is high, and the quality of a poured casting blank is good.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

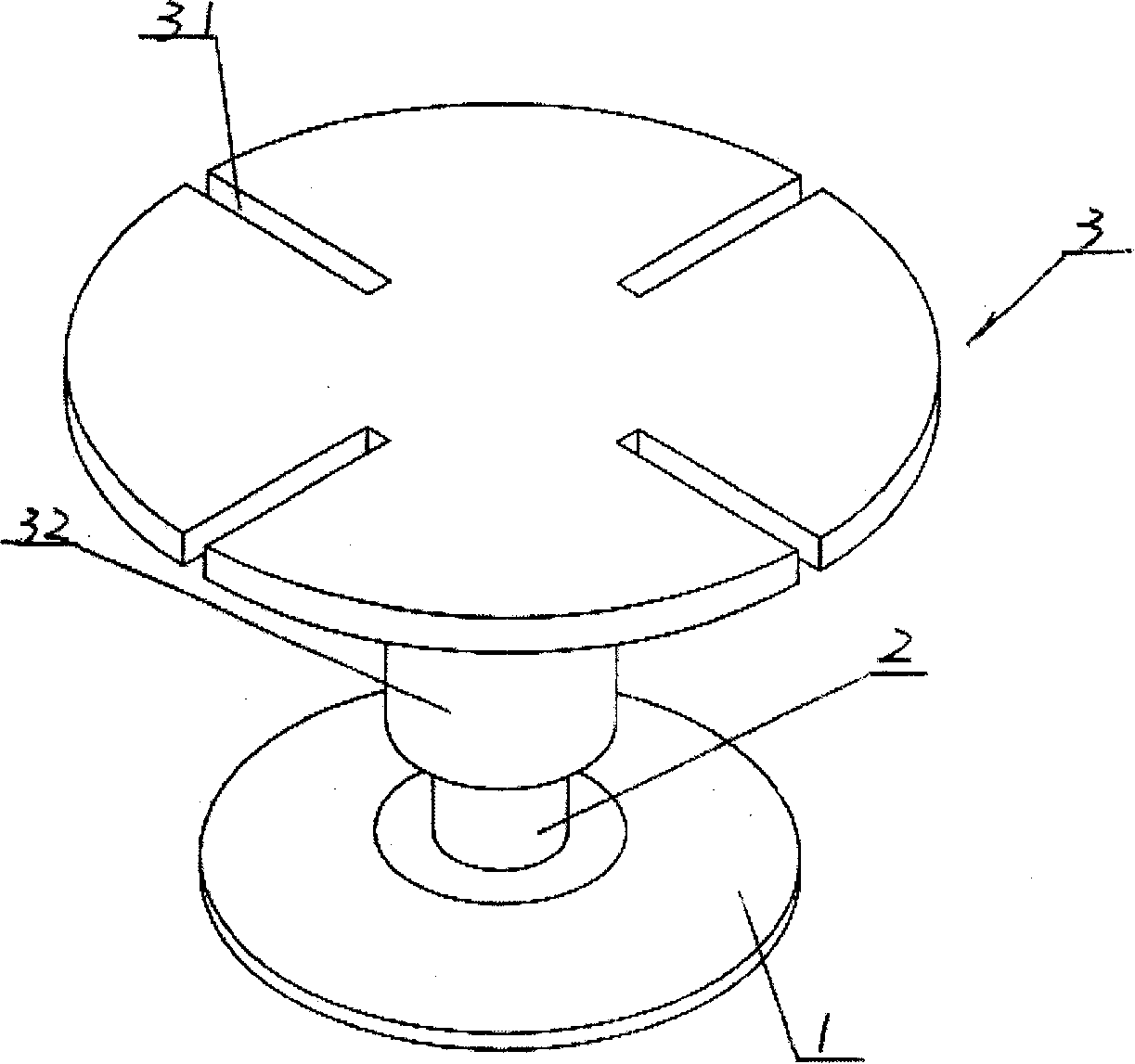

Rotating device for casting base pad

InactiveCN101209488AQuality improvementRealize continuous pouringIngot casting plantsMetallurgyMolten steel

The invention relates to a rotary bottom mat casting device which comprises a rotation axis restricted by a base and a bracing member used for fixing a mould and installed on the top of the rotation axis. By continuously rotating a bottom mat mould to realize continuous casting of the bottom mat, but the bottom mat module is unnecessary to be aligned with an opening of a ladel; therefore, by adopting the device, continuous casting of multi bottom mats with the same furnace of molten steel can be realized, efficiency can be improved, and the production cost can be reduced.

Owner:BENXI IRON & STEEL GROUP

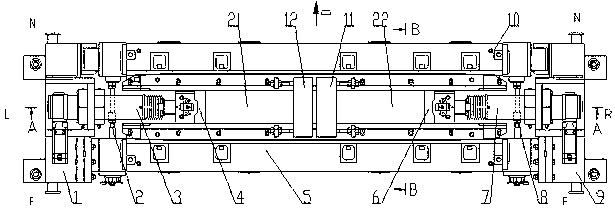

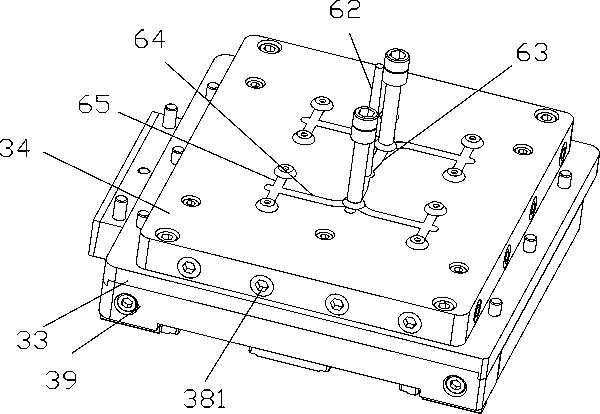

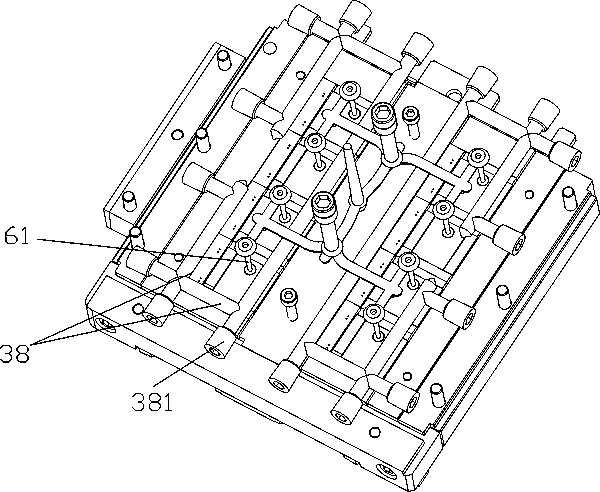

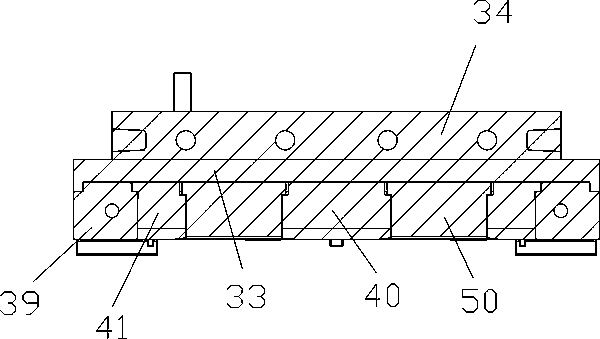

Automatic model board trolley for bridge crash barrier

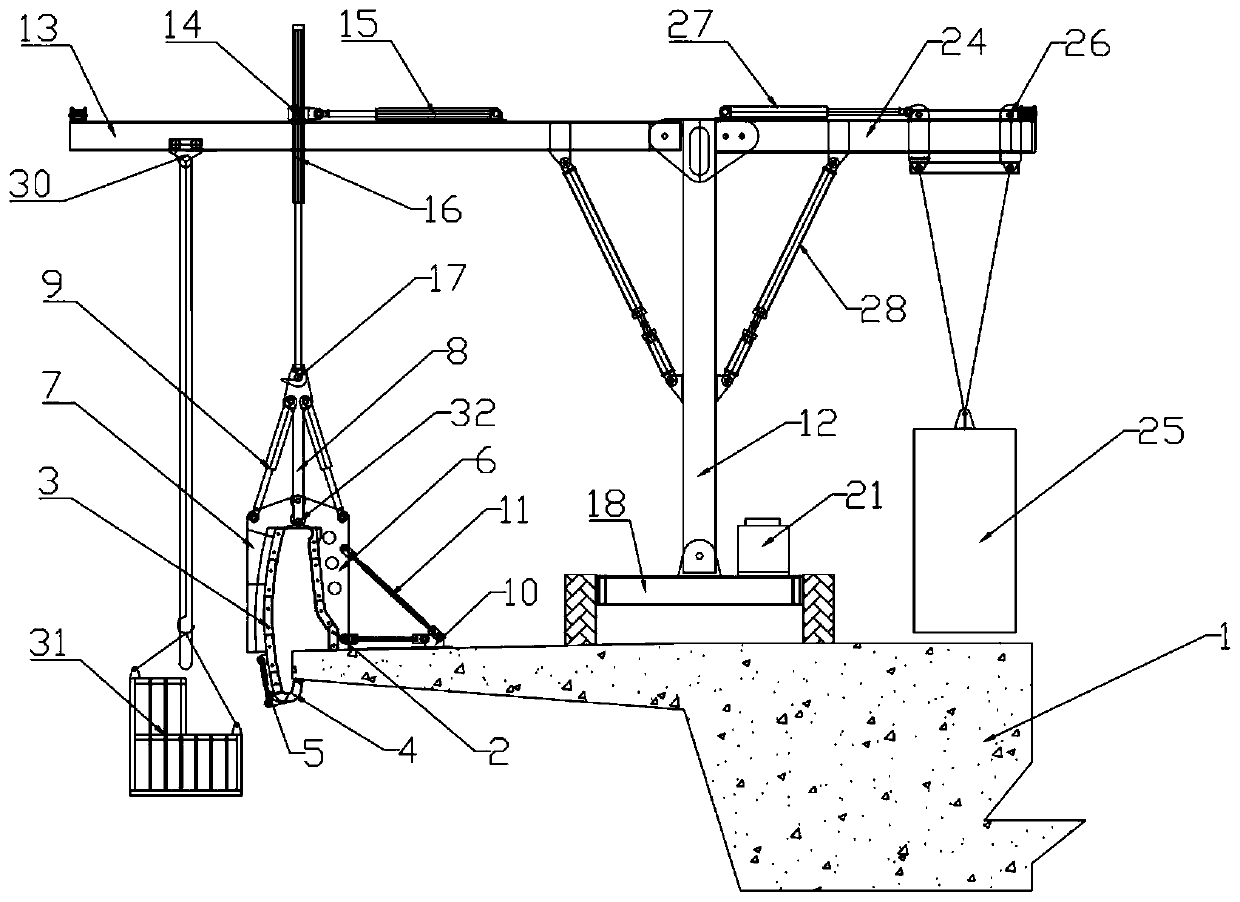

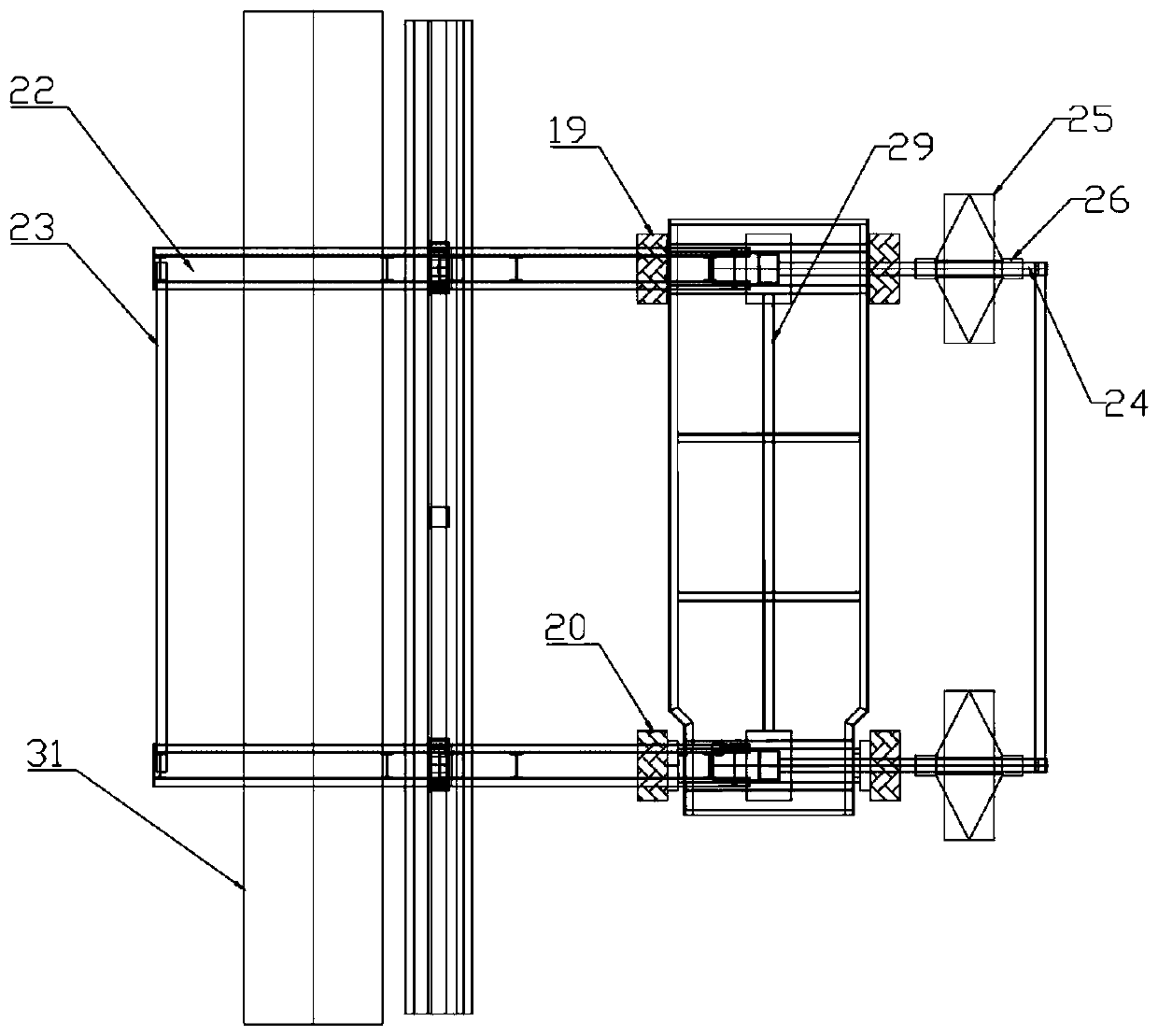

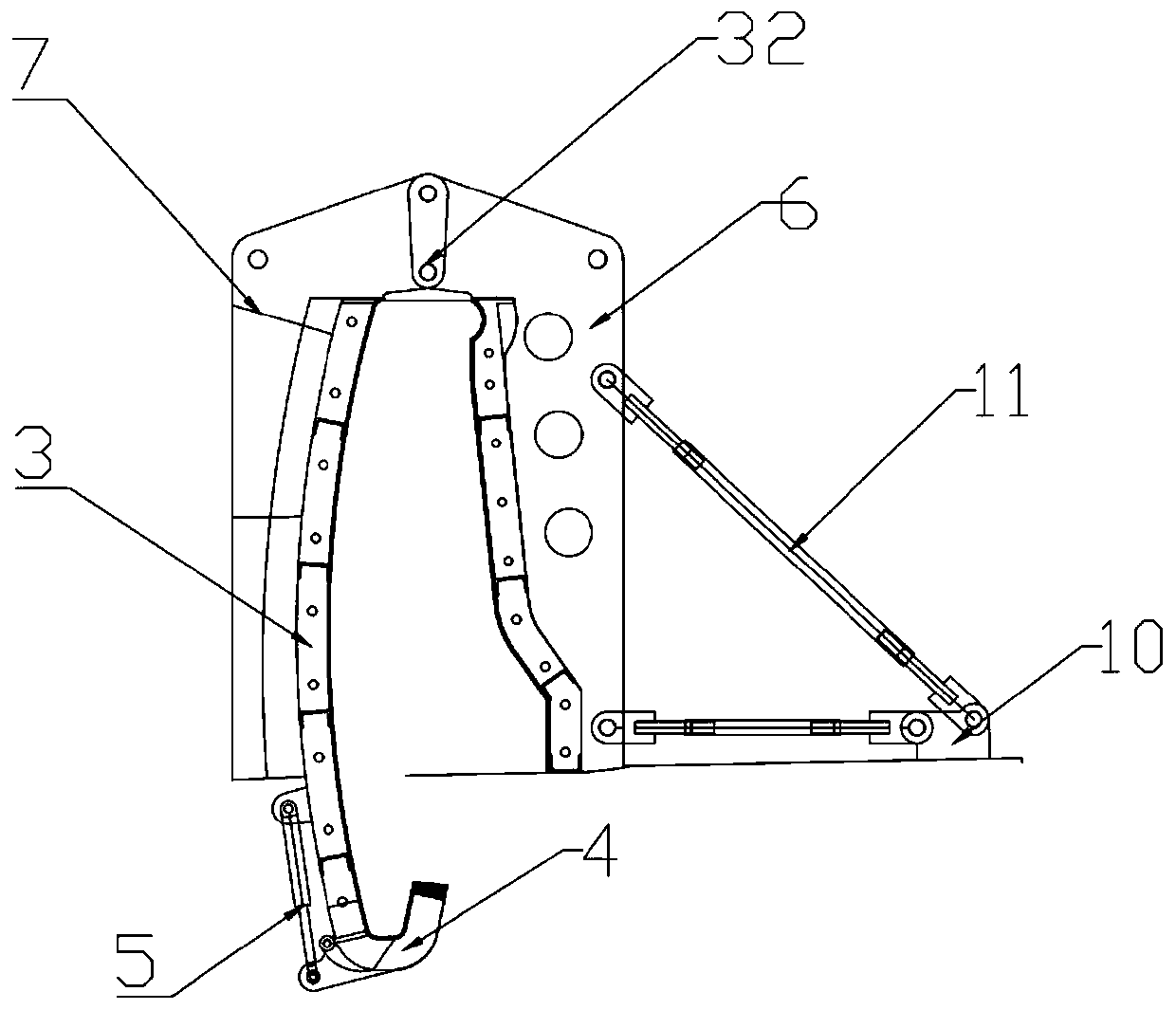

PendingCN111119048AReduce labor intensityImprove efficiencyBridge structural detailsBridge erection/assemblyArchitectural engineeringStructural engineering

The invention discloses an automatic model board trolley for a bridge crash barrier. The automatic model board trolley comprises a model board, a model board opening and closing mechanism arranged inthe length direction of the model board, and a hoisting device which is used for hoisting the model board opening and closing mechanism; the model board comprises an anti-collision guardrail inner model board body, an outer model board body and a water drop eave model board body. The model board opening and closing mechanism comprises inner and outer opening and closing plates fixed on the outer surfaces of the inner and outer model boards; the tops of the inner opening and closing plate and the outer opening and closing plate are mutually hinged, a hoisting rod is fixed at the hinged part, anopening and closing oil cylinder is connected between the hoisting rod and the inner opening and closing plate, a positioning base is fixed on a cast-in-place box girder, a positioning mechanism forfixing the model board opening and closing mechanism on the cast-in-place box girder is arranged between the positioning base and the inner opening and closing plate. The model board opening and closing automation is achieved through the model board opening and closing mechanism, the labor intensity of operators is reduced, the efficiency is improved, the utilization rate of the trolley is increased through the hoisting device and the walking mechanism, continuous pouring is achieved, the model board is fixed through the positioning mechanism, and model board deviation is prevented.

Owner:CCCC THIRD HARBOR ENG

Low-carbon aluminum-containing steel and smelting control method thereof

PendingCN112322958AImprove pourabilityReduce erosionManufacturing convertersProcess efficiency improvementAluminateSlag

The invention relates to the field of steel smelting, in particular to low-carbon aluminum-containing steel and a smelting control method thereof. The method comprises the following steps of controlling the endpoint carbon content in molten steel to range from 0.08 percent to 0.12 percent during converter tapping; carrying out decarburization treatment on the molten steel by adopting a vacuum degassing process; adding aluminum into the molten steel for carrying out deoxidation; and after refining is finished, conducting calcium treatment on the molten steel. The carbon content in the converterendpoint molten steel is controlled to range from 0.08 percent to 0.12 percent , so that the oxidability of the molten steel and the erosion of the high-temperature molten steel to a furnace lining are reduced, and the service life of a converter is prolonged. Meanwhile, an oxygen source can be brought to natural decarburization under the subsequent vacuum degassing condition, and conditions arecreated for VD natural decarburization. A VD treatment process is adopted for decarburization, so that carbon is lower after decarburization is finished. The aluminum is added for deoxidation, so thatthe deoxidation efficiency can be improved, and the deoxidation speed is high. The deoxygenation of refining slag is facilitated. After LF treatment is finished, the molten steel is subjected to calcium treatment, inclusions can be subjected to denaturation treatment, so that low-melting-point calcium aluminate is formed, and the castability of the molten steel is improved.

Owner:SGIS SONGSHAN CO LTD

Clay tunnel steel lining concrete pouring anti-floating structure and construction method

ActiveCN112627854ARealize continuous pouringResistance to pouring buoyancyUnderground chambersHydro energy generationBuoyant flowStructure support

The invention provides a clay tunnel steel lining concrete pouring anti-floating structure and a construction method. A steel lining is arranged in a clay tunnel; two semi-annular steel arch supports are arranged on the inner wall of the tunnel and connected at the waist of the tunnel through a splicing plate structure; the steel arch supports are arranged in a concrete layer on the inner wall of the tunnel; a concrete bottom plate is arranged at the bottom of the tunnel; I-shaped steel is arranged in the concrete bottom plate; a nail plate is arranged at the top arch position of the tunnel; the splicing plate structure, the I-shaped steel and the nail plate are connected with a stiffening ring of the steel lining; and a telescopic combined supporting structure is arranged in the steel lining. Various construction defects caused by layered pouring and common steel lining inner supports are overcome, concrete pouring buoyancy can be effectively resisted, continuous pouring of backfill concrete is achieved, and damage to the inner surface of the steel lining and secondary painting of anti-corrosion materials during inner support installation are avoided.

Owner:POWERCHINA HUADONG ENG COPORATION LTD +1

Construction method of air coating material with additionally-added synergist in road

InactiveCN108049270AReduce dosageIncreased hydrationRoadwaysCeramicwareMaterials scienceFoam concrete

The invention discloses a construction method of an air coating material with an additionally-added synergist in a road. The construction method includes the following steps of (1) construction site preparation, (2) concrete synergist preparation, (3) concrete slurry preparation, (4) foam preparation, (5) foam concrete preparation, (6) foam concrete pouring, and (7) foam concrete curing. By the adoption of the construction method of the air coating material with the additionally-added synergist in the road, the use amount of cement can be reduced, the hydration degree of cement minerals is increased, the number of gels is increased through promotion of hydration of the minerals difficult to hydrate, and the strength of foam concrete is improved. Meanwhile, by the adoption of a constructionprocess of the cast-in-place foam concrete, continuous pouring can be simply, conveniently and efficiently achieved, and the pouring quality of the cast-in-place foam concrete meets the site construction requirements.

Owner:GUYAN TECH DEV CO LTD

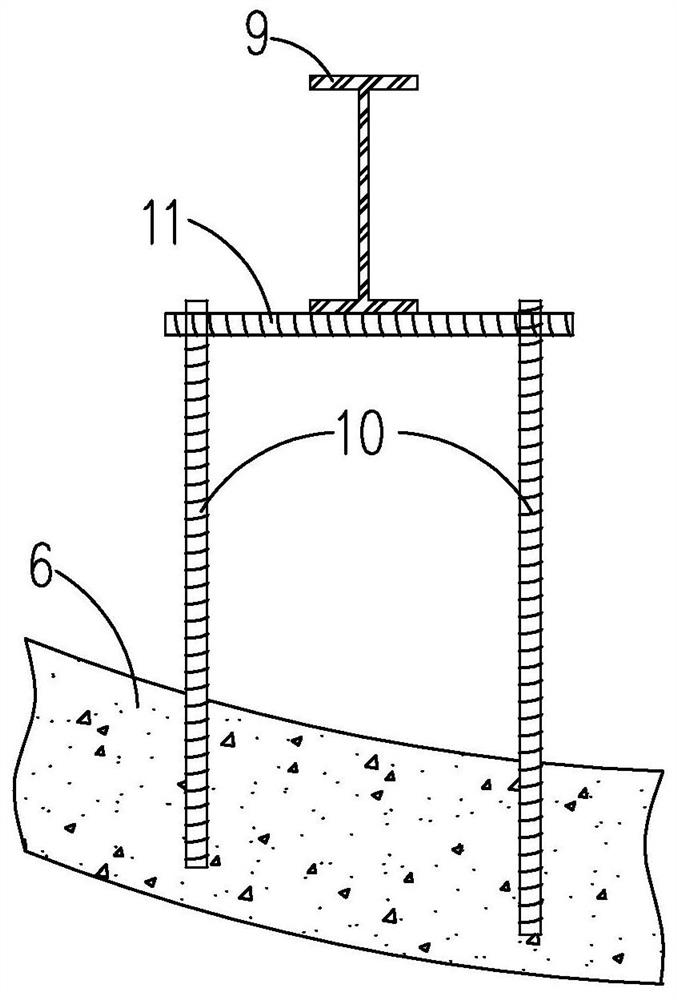

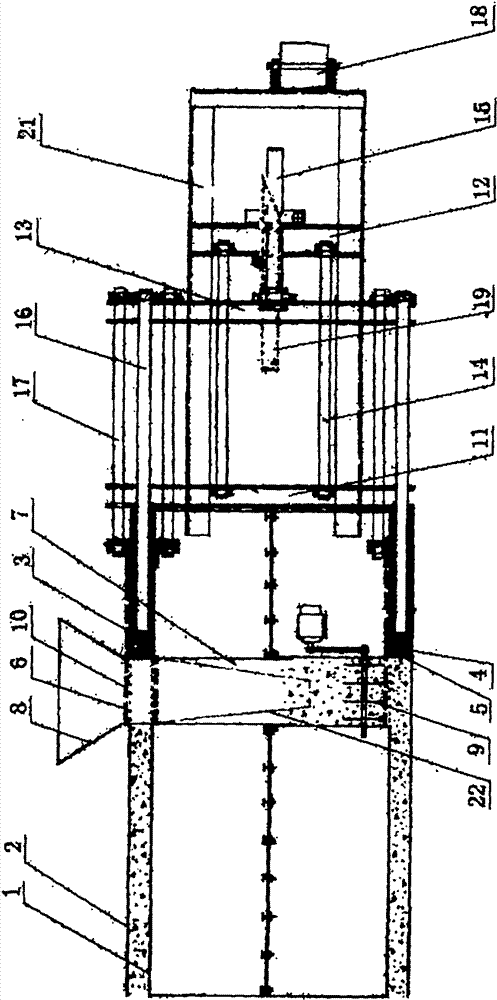

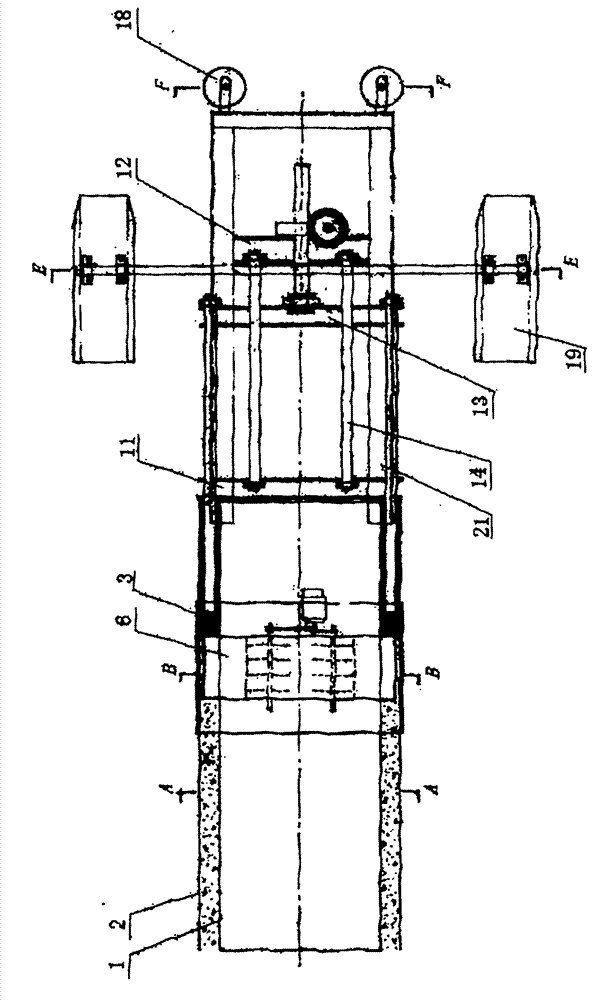

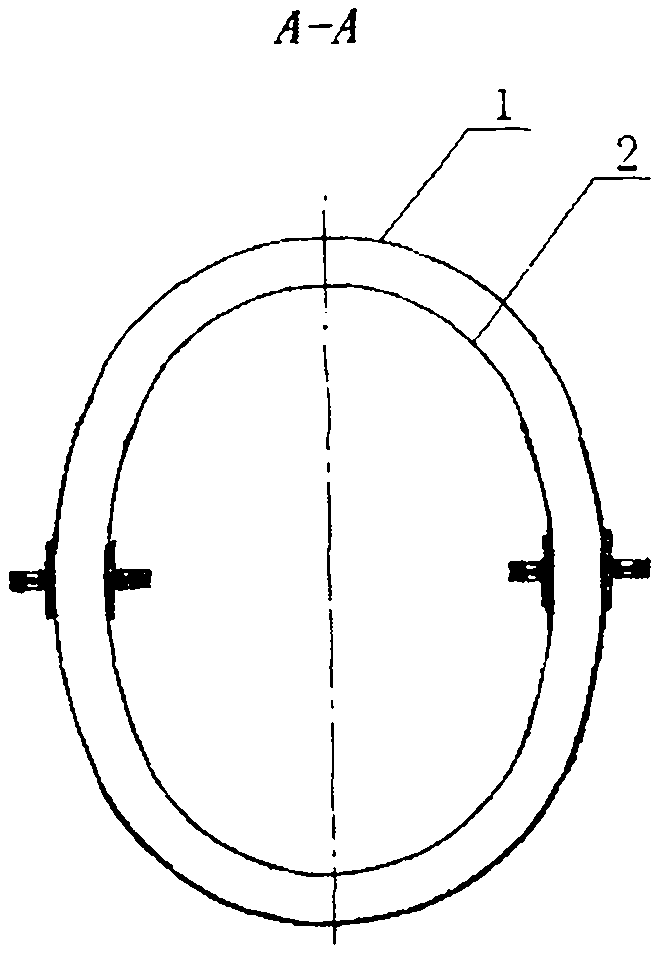

Agricultural integral continuous extrusion forming machine for elliptic concrete pipe

InactiveCN102267169BRealize continuous pouringPrevent leakageCeramic shaping apparatusEngineeringMechanical engineering

The invention relates to an agricultural integral continuous extrusion forming machine for an elliptic concrete pipe. The forming machine comprises a frame, a pipe compression forming mechanism arranged at the front end of the frame, a feeding mechanism arranged on the pipe forming mechanism, a power propulsion mechanism arranged on the frame, and a guiding sliding mechanism. During construction,the forming machine is placed in a pre-dug groove, concrete enters an elliptic annular die cavity of the pipe compression forming mechanism through a feeding hole and a feeding passage of the feedingmechanism, and an elliptic annular compression piston moves forwards under the action of the power propulsion mechanism to extrude and compact the concrete; and when the compression piston cannot further propel the concrete in the cavity, the forming machine is subjected to the reacting force of the concrete and continuously moves forwards under the guide of the guiding sliding mechanism so as torealize integral continuous casting of the elliptic annular pipe. The caliber of the cast-in-place continuous extrusion elliptic concrete pipe reaches 600 to 2,000 millimeters; and the forming machine has the advantages of one-time casting forming, leakage prevention and high casting efficiency, and reduces the production cost.

Owner:如皋大禹地下管道成型机研究所

Construction method of corrosion resistant silica fume binding material in highway

ActiveCN108218472ASimple and efficient construction processRealize continuous pouringRoadwaysCeramicwareFoam concreteFoaming agent

The invention discloses a construction method of a corrosion resistant silica fume binding material in a highway. The construction method comprises the following steps that (1) silica fume cement slurry is prepared, specifically, silica fume, cement, mineral powder, coal ash and gypsum are mixed with bauxite, and then mixed with water, and the silica fume cement slurry is obtained; (2) foam is prepared, specifically, a foaming agent solution is promoted to foam, and the foam is obtained; (3) foam silica fume concrete is prepared, specifically, the silica fume cement slurry and the foam are mixed, and the foam silica fume concrete is obtained; (4) the foam silica fume concrete is poured, specifically, the foam silica fume concrete is conveyed to a highway construction area through a pipeline, and automatic flowing and pouring are conducted; and (5) the foam silica fume concrete is maintained, specifically, after the foam silica fume concrete is finally set, watering maintenance is conducted. The construction method provided by the invention applies corrosion resistant silica fume binding material to high filling of the highway with foam concrete, the construction technology is simple, convenient and efficient, continuous pouring can be achieved, and the pouring quality conforms to the requirement of site construction.

Owner:广东同创科鑫环保有限公司

Rare earth steel production method for preventing continuous casting nozzle from nodulating

InactiveCN113122767ASolve the blockageRealize continuous pouringProcess efficiency improvementDeoxidized steelSulfur content

The invention belongs to the technical field of steelmaking, and relates to a rare earth steel production method for preventing a continuous casting nozzle from nodulating. The method comprises the procedures of electric arc furnace primary smelting, eccentric bottom tapping and deoxidation, furnace rear slagging-off, LF furnace slagging refining, RH vacuum refining, soft blowing treatment and continuous casting. In the electric arc furnace primary smelting procedure, furnace charge is direct reduced iron and low-sulfur waste steel, and the sulfur content in terminal steel of an electric arc furnace is controlled to be smaller than or equal to 0.006%; the eccentric bottom tapping technology is adopted, the slag amount of tapping is reduced, meanwhile, deoxidation is conducted in the tapping process, and the oxygen content in the deoxidized steel is smaller than or equal to 0.001%; in the furnace rear slagging-off procedure, slag formed in the electric arc furnace tapping process is removed; pre-melted refining slag and lime are added into an LF refining furnace again for slagging refining, the sulfur content in steel is controlled to be smaller than or equal to 0.0020% after LF refining is completed, and the oxygen content in the steel is controlled to be smaller than or equal to 0.001% in the LF refining process; a rare earth alloy is added in the RH vacuum refining process, and the nitrogen content in steel in the process is controlled to be smaller than or equal to 0.003%; and in the continuous casting process, argon is adopted for whole-process sealing protection, and the continuous casting nitrogen increasing amount is controlled to be smaller than or equal to 0.0003%.

Owner:JIANGSU UNIV +1

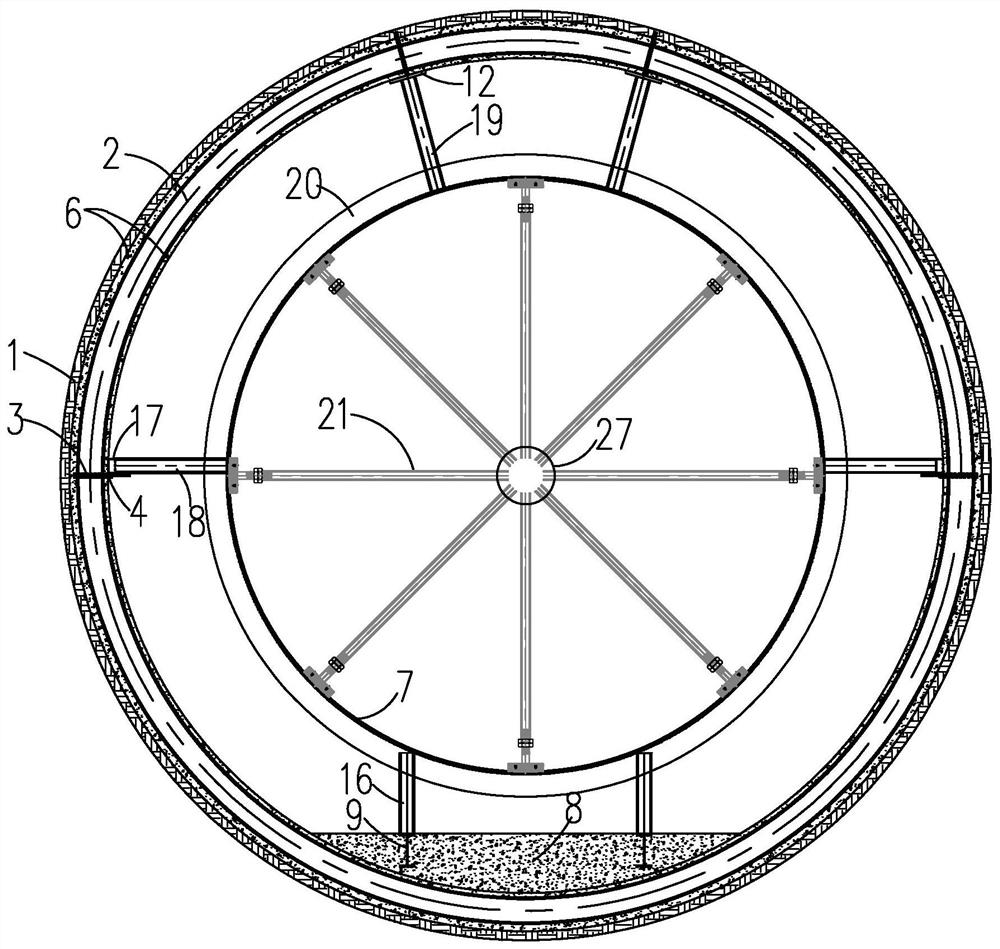

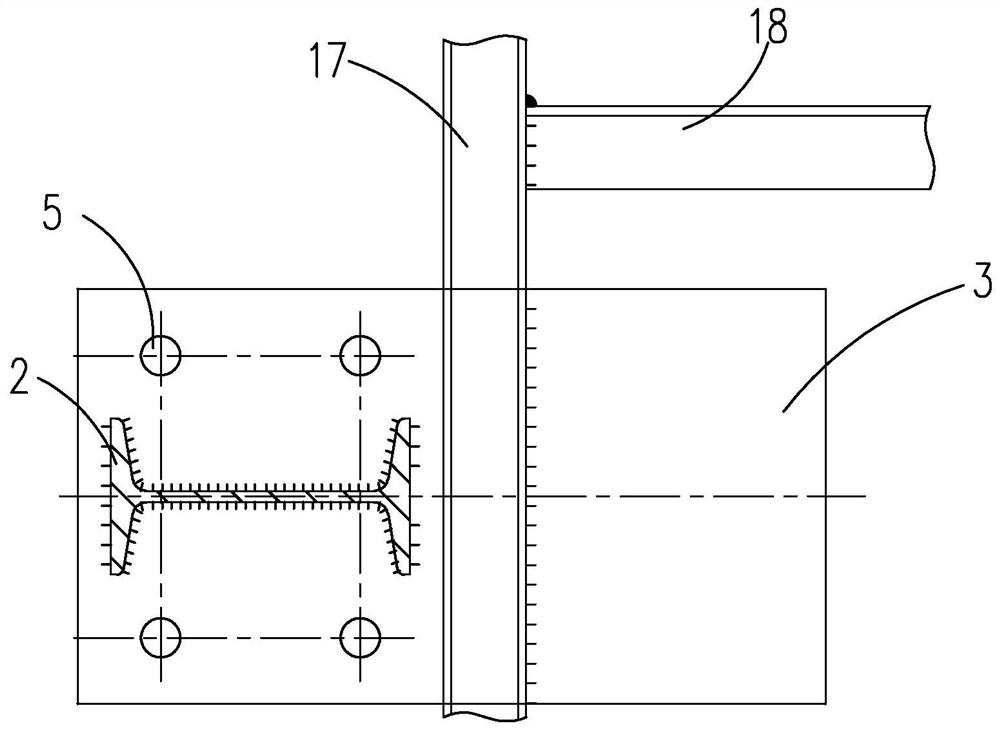

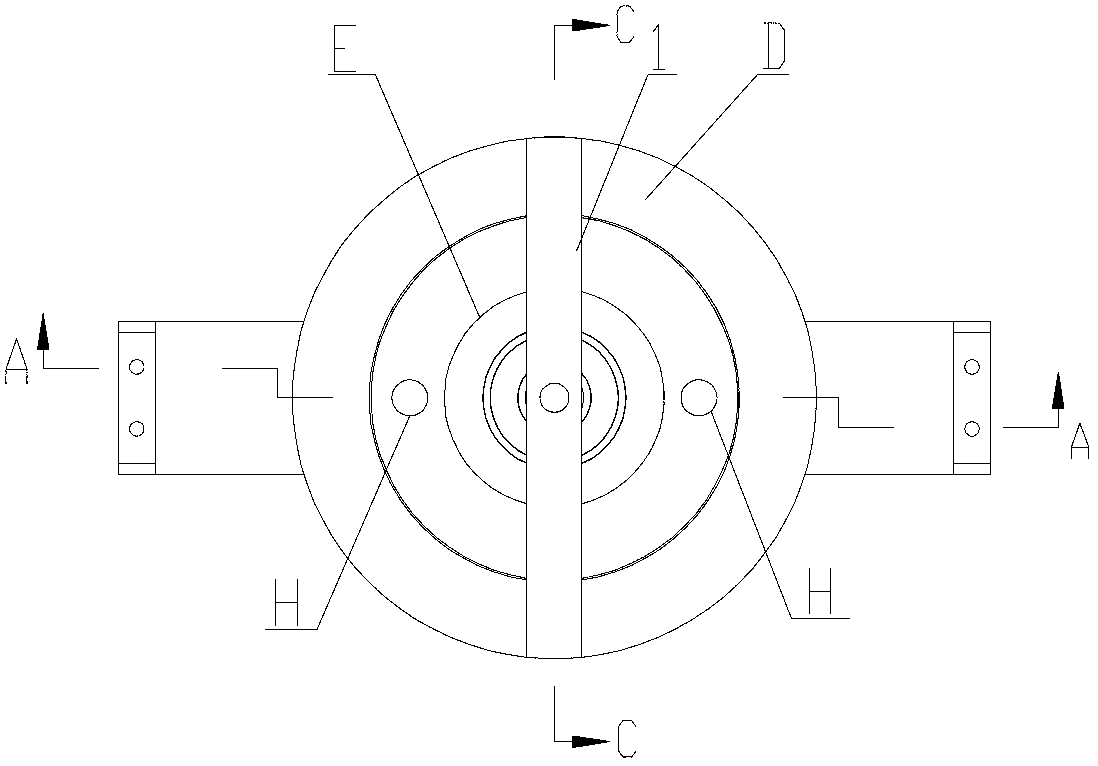

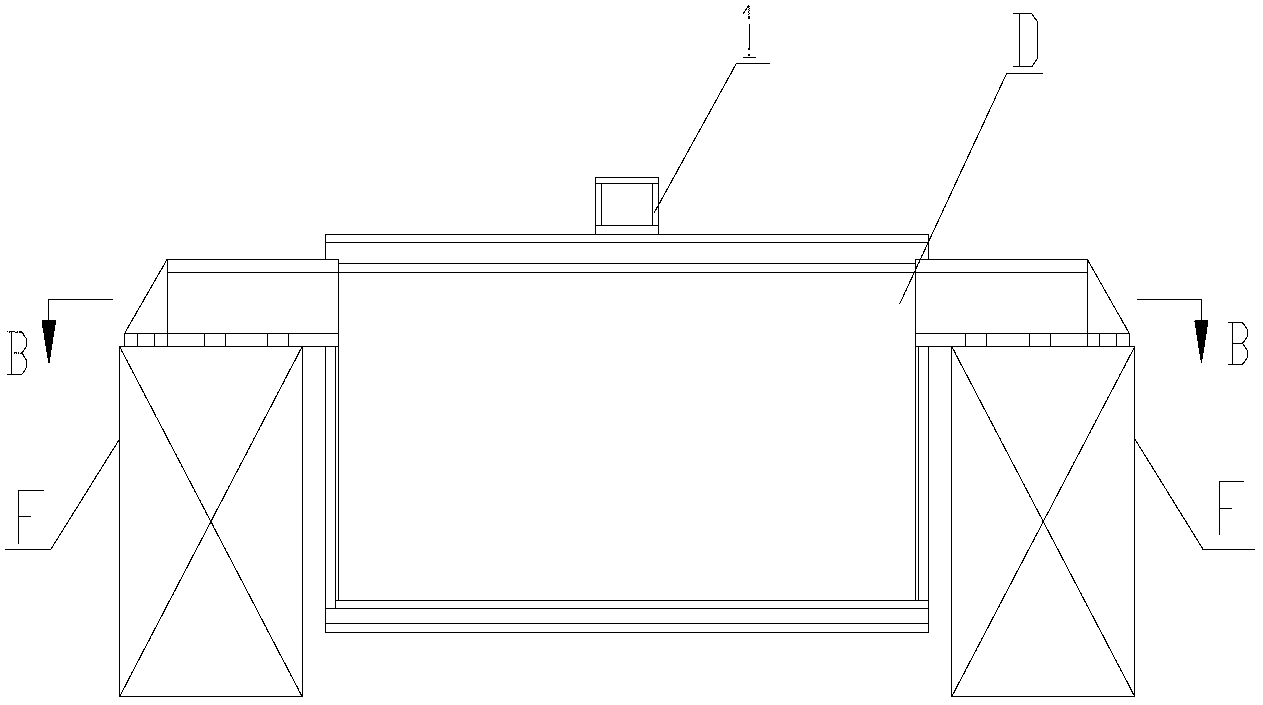

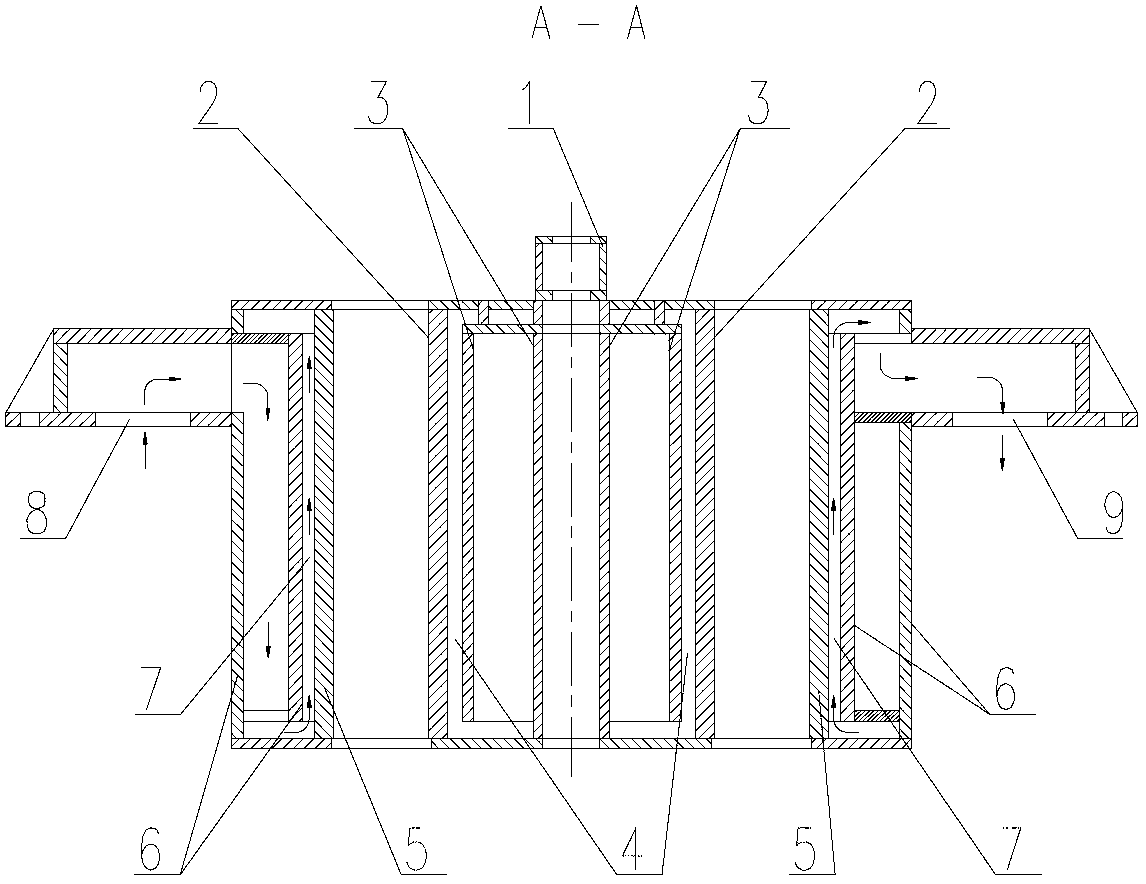

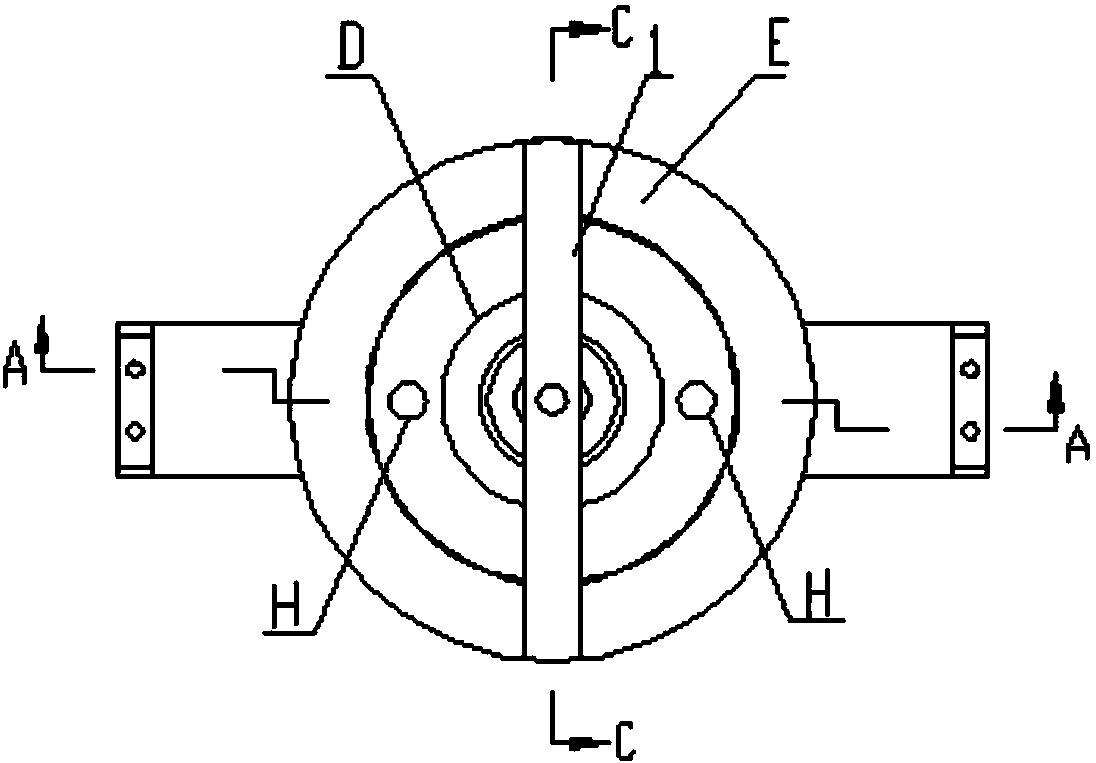

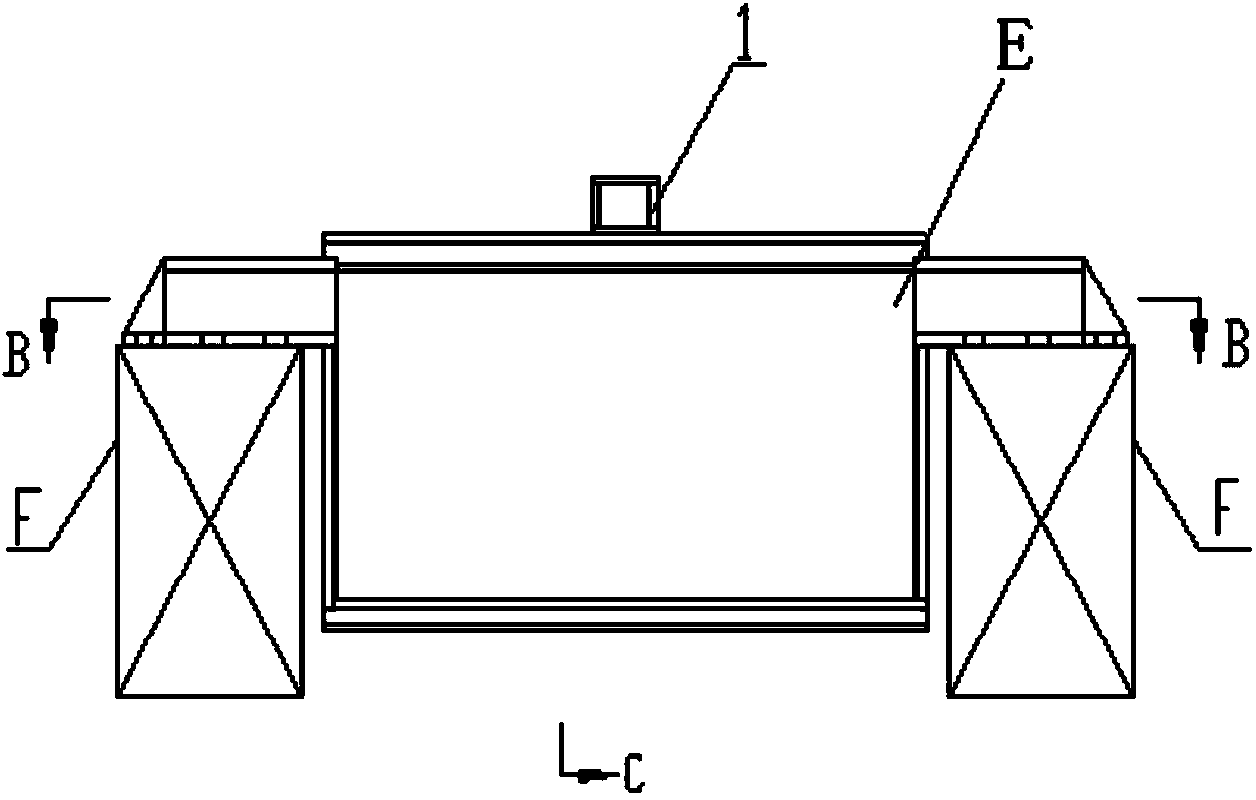

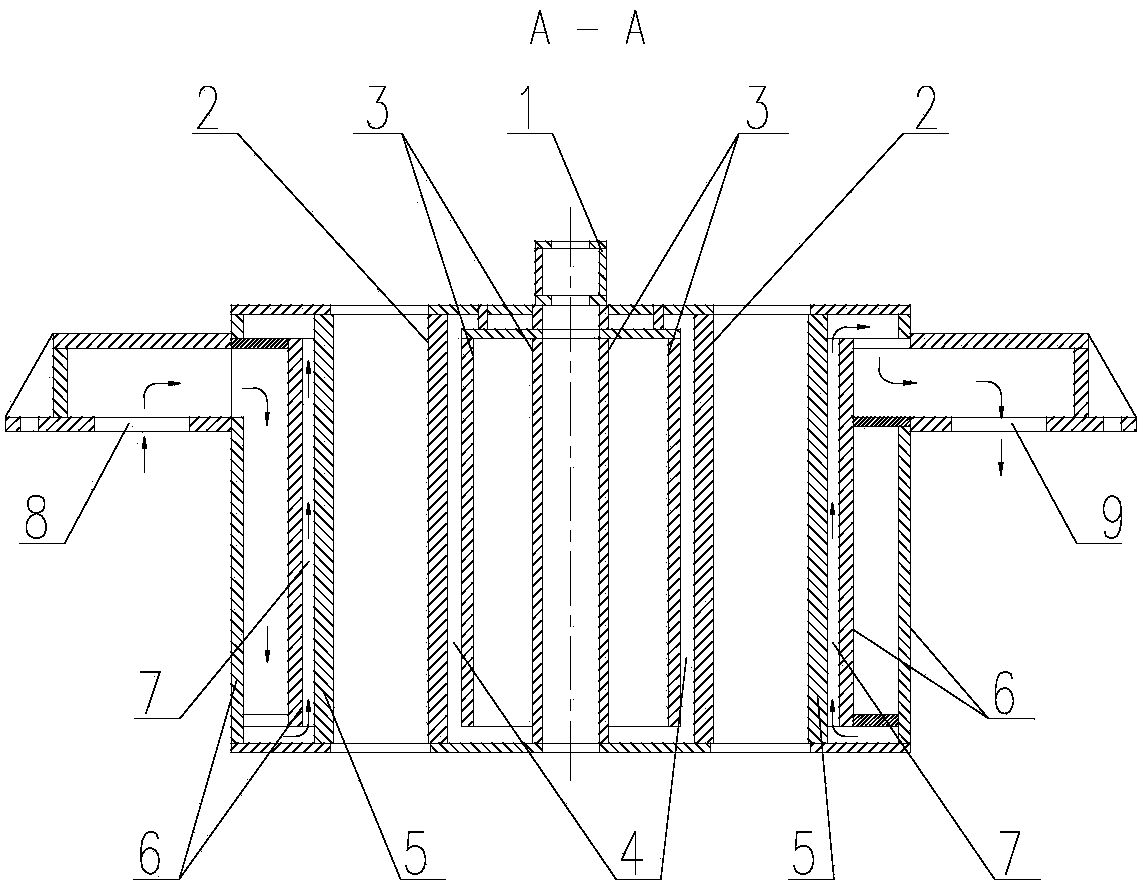

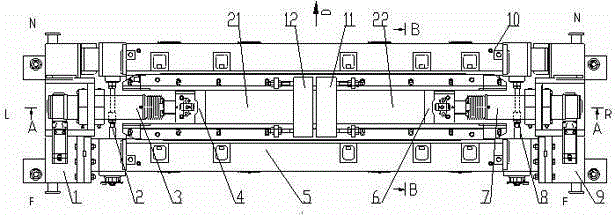

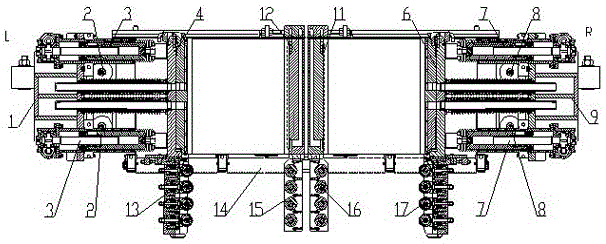

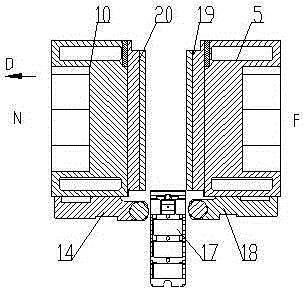

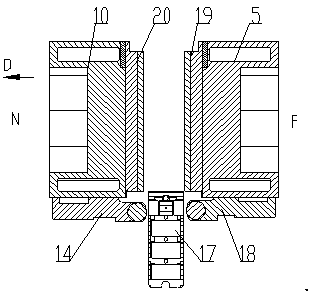

Crystallizer device for continuously casting hollow tube blanks

The invention discloses a crystallizer device for continuously casting hollow tube blanks. The crystallizer device for continuously casting the hollow tube blank comprises an inner copper tube assembly and an outer copper tube assembly which are connected integrally through a connecting beam, wherein the inner copper tube assembly comprises a water seam formed between an inner copper tube and an inner frame; the outer copper tube assembly comprises a water seam formed between the outer copper tube and the outer frame; cooling water inlet and outlet of the outer copper tube which are communicated with a vibration device are arranged at the left end and the right end of the outer copper tube; and cooling water inlet and outlet of the inner copper tube which are communicated with the vibration device are arranged at the left end and the right end of the outer copper tube. As continuous casting of the hollow tube blanks is realized through the inner copper tube assembly and the outer copper tube assembly, the crystallizer device for continuously casting the hollow tube blanks, disclosed by the invention, has the advantages of reducing production cost and saving resource. The continuous casting method has certain promotional value.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Building construction method of modular house

InactiveCN112681510ASimple preparation stepsSave materialBuilding material handlingFoam concreteConstruction engineering

The invention provides a building construction method of a modular house. The building construction method comprises the steps of S1, design of the modular house; S2, main body production; S3, foundation arrangement; S4, erection of embedded parts; S5, connection of stand columns; S6, laying of ground beams; S7, splicing of wall bodies; S8, installation of roof components; and S9, pouring of foam concrete. The preparation steps of the modular house are simple, cavities in the wall bodies are poured by adopting the foam concrete, materials are saved, continuous pouring is achieved, the pouring time is shortened, the building cost is reduced, waste materials in the construction process are few, and people can live in the house without being decorated again after construction.

Owner:TIANJIN YUANTAI MODULE HOUSING MFG

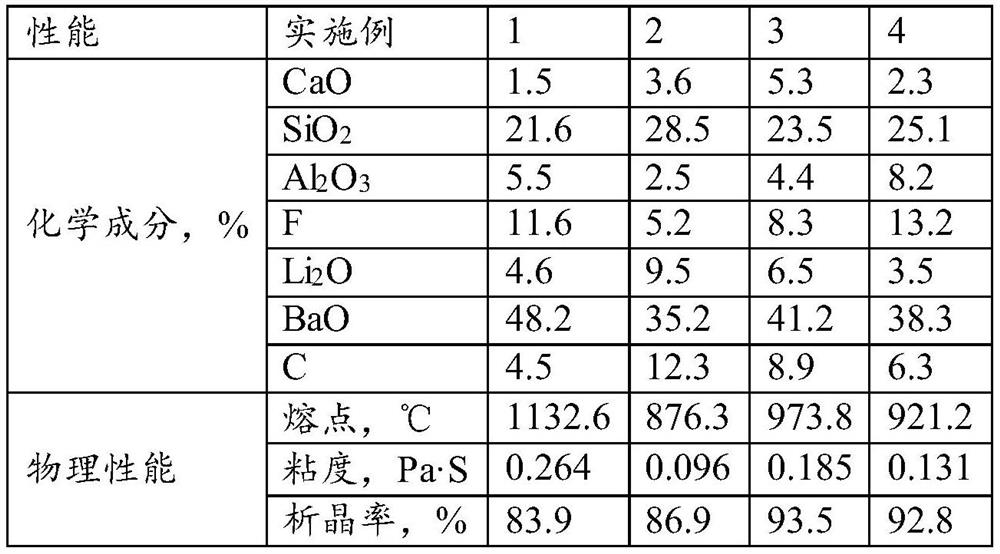

Continuous casting covering slag for high-titanium steel and preparation method of continuous casting covering slag

The invention provides continuous casting covering slag for high-titanium steel. The continuous casting covering slag comprises the following components: 0-6 wt% of CaO; 20-30 wt% of SiO2; 0-10 wt% of Fe2O3; 5-14 wt% of F; 3-10 wt% of LiO2; 35-50 wt% of BaO; 3-15 wt% of C; and the balance of impurities. Aiming at the high-titanium steel, the crystallizer covering slag suitable for continuous casting pouring is designed and developed; according to the covering slag, the reactivity of substances such as Fe2O3, Al2O3, Na2O and B2O3 with titanium in the steel is effectively reduced, so that the performance of the covering slag is stabilized; and in addition, the content of CaO in the covering slag is greatly reduced, the production of high-melting-point perovskite is effectively prevented, and the performance stability of the high-titanium steel in the pouring process is ensured. The invention further provides a preparation method of the continuous casting covering slag for the high-titanium steel.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

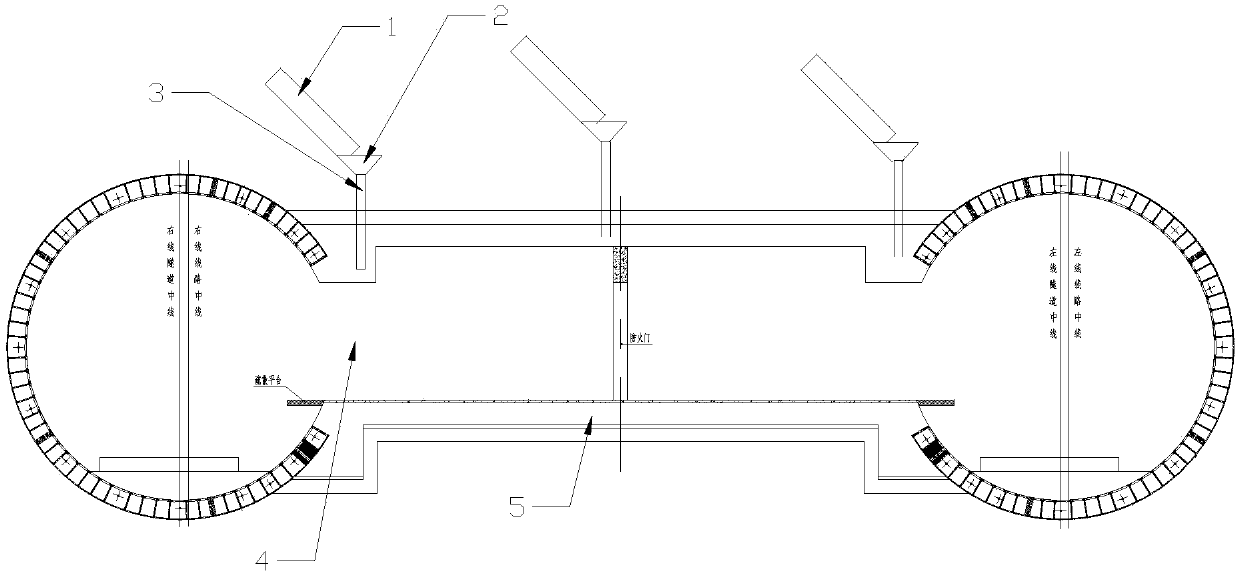

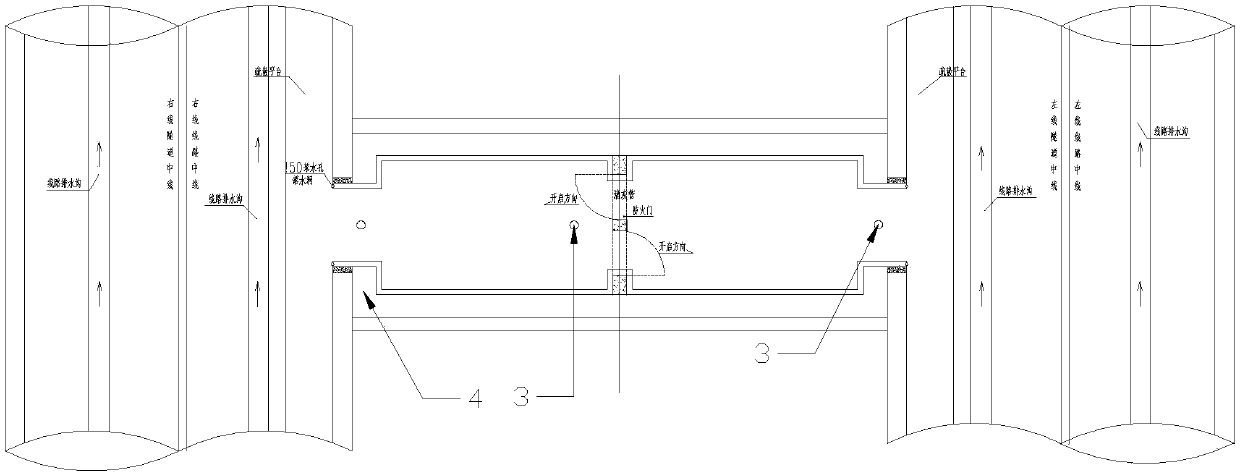

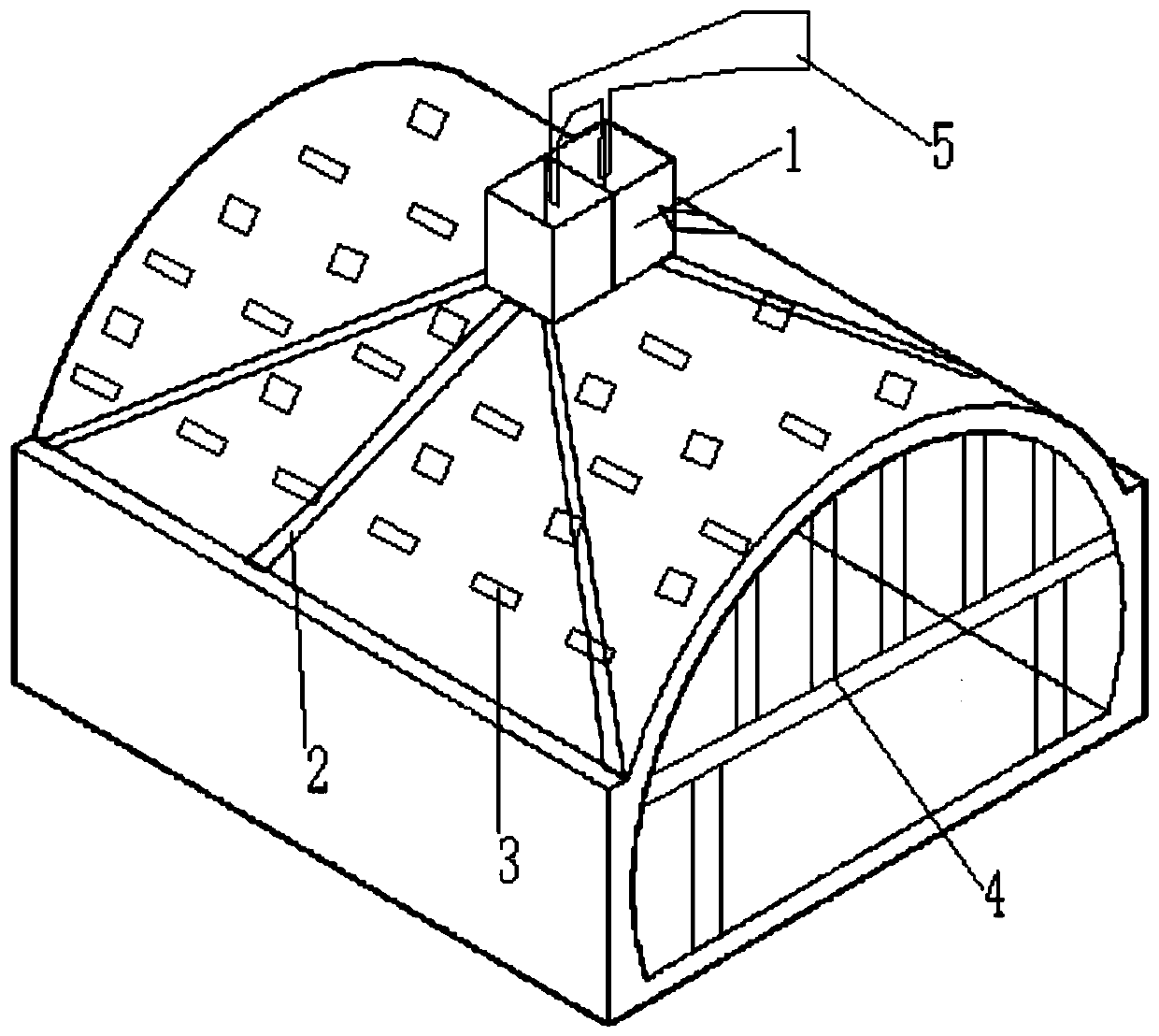

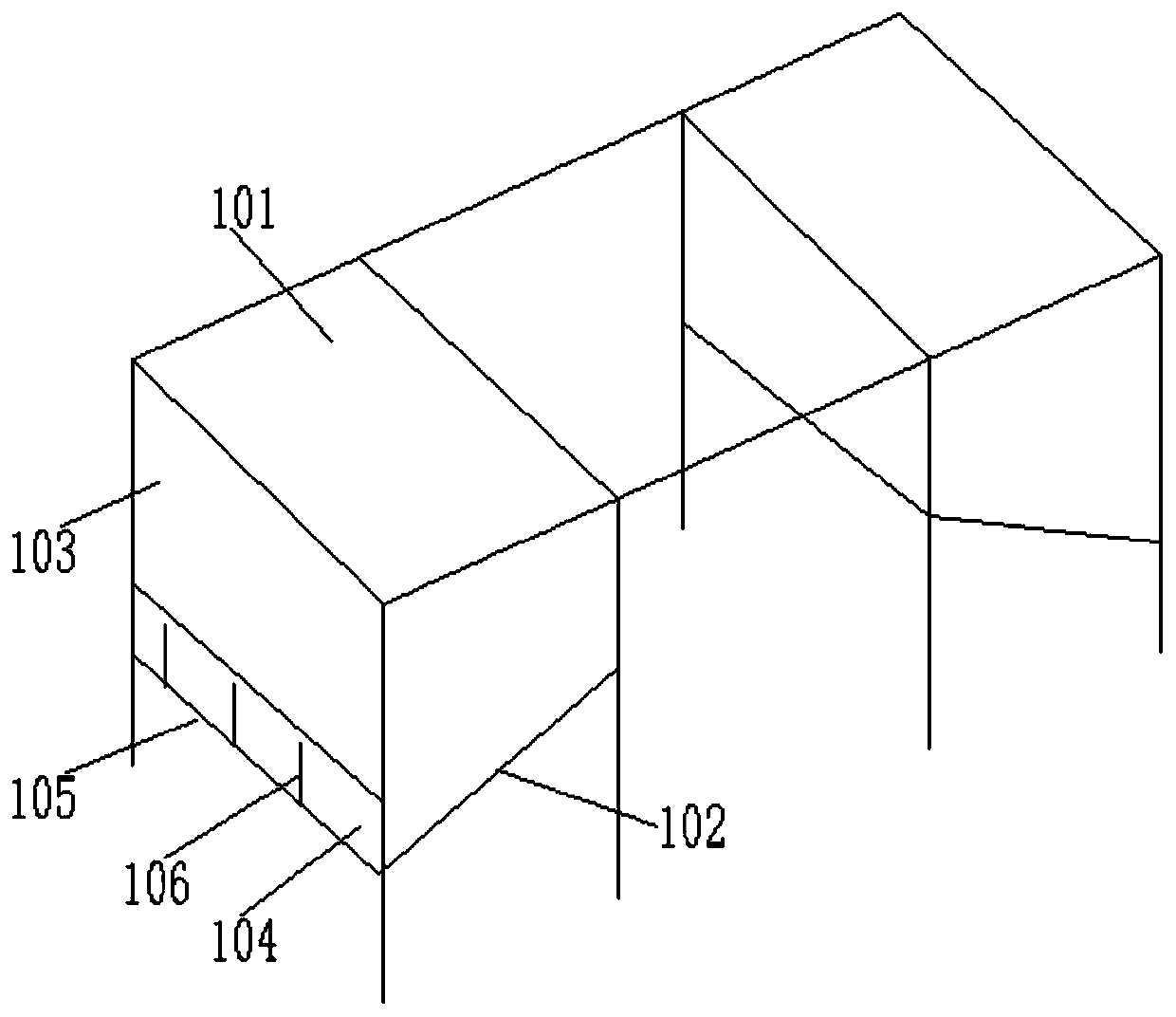

Symmetrical synchronous layered distributing and casting system and construction method for open trench tunnel lining

PendingCN110965580AFast constructionAvoid repeated transfersArtificial islandsUnderwater structuresSemi automationStructural engineering

The invention discloses a symmetrical synchronous layered distributing and casting system for an open trench tunnel lining. The symmetrical synchronous layered distributing and casting system for theopen trench tunnel lining comprises a central aggregate groove, multiple casting tumbling barrels, multiple silos, aggregate funnels and multiple distributing sliding chutes, wherein the central aggregate groove is fixed to the center of a lining formwork arch apex and is provided with multiple independent discharge holes; the multiple casting tumbling barrels are fixed into a lining side wall atintervals; the multiple silos are arranged in a layered way; the aggregate funnels are in one-to-one correspondence to the casting tumbling barrels; the lower end ports of the aggregate funnels communicate with the upper end ports of the casting tumbling barrels; the multiple distributing sliding chutes correspond to the multiple discharge holes; and the lower ends of the distributing sliding chutes are located at upper openings of the aggregate funnels or located at distributing trough ports of the silos located on one same layer. The invention further discloses a symmetrical synchronous layered distributing and casting construction method for the open trench tunnel lining. The symmetrical synchronous layered distributing and casting system and the symmetrical synchronous layered distributing and casting construction method for the open trench tunnel lining provided by the invention have the advantages of high construction efficiency, simplicity in operation, reduction in labor intensity, capability of realizing semi-automatic casting, cleanliness in construction due to no concrete drop on site, environment protection without pollution, and the like.

Owner:CCCC SECOND HARBOR ENG +1

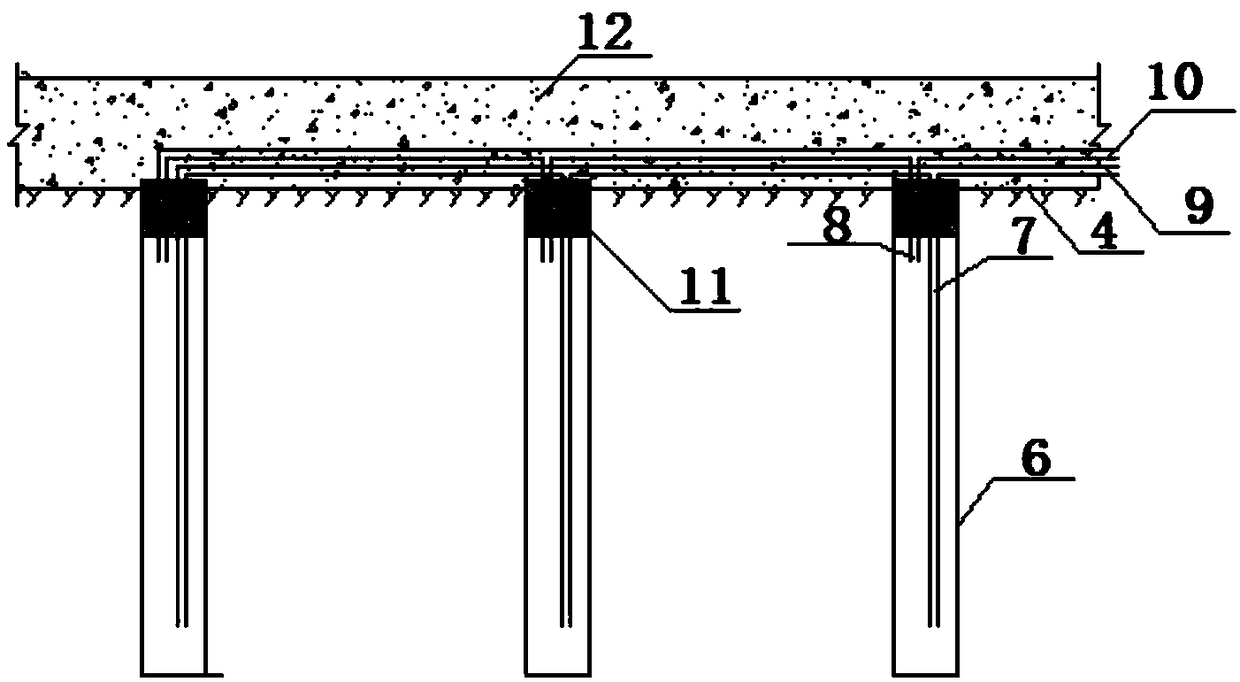

Large-area overwater support pouring method

InactiveCN106939606ARealize continuous pouringReduce construction costsFoundation engineeringMaterials scienceGlobe valve

The invention discloses a method for pouring a large-area above-water support. The specific technical scheme is: ground pump pipe arrangement, concrete pouring of the first concrete support, concrete pouring of the next concrete support and pouring of the remaining concrete supports. The large-area water support pouring method proposed by the present invention is simple and easy to operate. After each support is poured, workers do not need to re-distribute pipes, and only need to manually switch the stop valve to realize continuous pouring of large-area water support concrete. The pouring time is greatly saved, and the construction cost of the project is reduced.

Owner:CHINA MCC17 GRP

Free face transverse slip form concrete pouring device

InactiveCN110700099ARealize continuous pouringBridge erection/assemblyReinforced concreteArchitectural engineering

The invention discloses a free face transverse slip form concrete pouring device including afixing device, the lower end of the fixing device is fixedly connected with a first pulley; the middle partof the fixing device is connected with a steel box girder bridge floor; a guide rail part is fixedly connected to the upper end of the fixing device, a guide rail is fixedly connected to the lower portion of the guide rail part, a second pulley is movably connected to the guide rail, a support is fixedly connected to a middle shaft of the second pulley, a steel rope is fixedly connected to the support, and a reinforced concrete formwork is fixedly connected to the lower end of the steel rope. According to the device, through cooperative use of the first pulley and the second pulley, continuouspouring work of free face concrete is completed, the formwork dismounting process is simple, and the construction period is short.

Owner:CHINA MCC17 GRP

Mold Mold Flux for Improving the Service Life of Submerged Nozzle

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Crystallizer device for continuously casting hollow tube blanks

The invention discloses a crystallizer device for continuously casting hollow tube blanks. The crystallizer device for continuously casting the hollow tube blank comprises an inner copper tube assembly and an outer copper tube assembly which are connected integrally through a connecting beam, wherein the inner copper tube assembly comprises a water seam formed between an inner copper tube and an inner frame; the outer copper tube assembly comprises a water seam formed between the outer copper tube and the outer frame; cooling water inlet and outlet of the outer copper tube which are communicated with a vibration device are arranged at the left end and the right end of the outer copper tube; and cooling water inlet and outlet of the inner copper tube which are communicated with the vibration device are arranged at the left end and the right end of the outer copper tube. As continuous casting of the hollow tube blanks is realized through the inner copper tube assembly and the outer copper tube assembly, the crystallizer device for continuously casting the hollow tube blanks, disclosed by the invention, has the advantages of reducing production cost and saving resource. The continuous casting method has certain promotional value.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

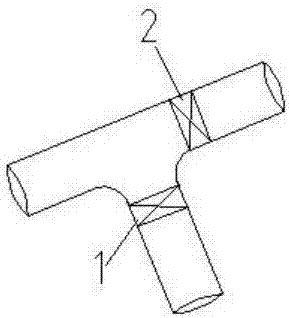

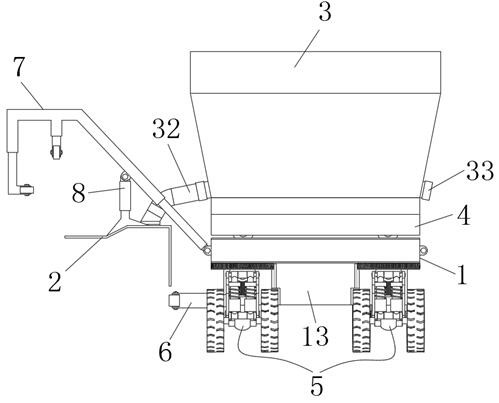

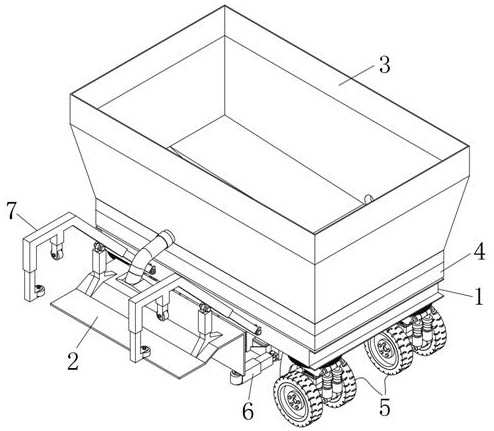

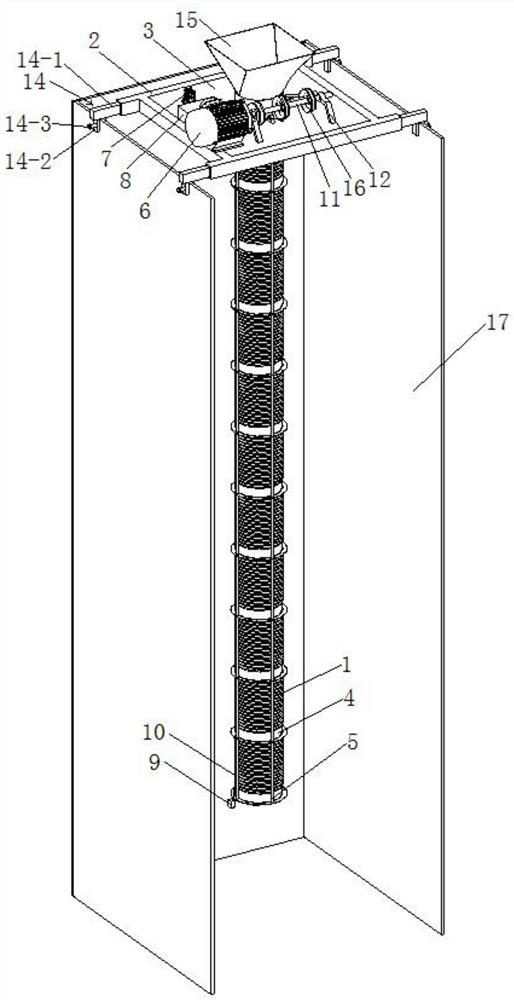

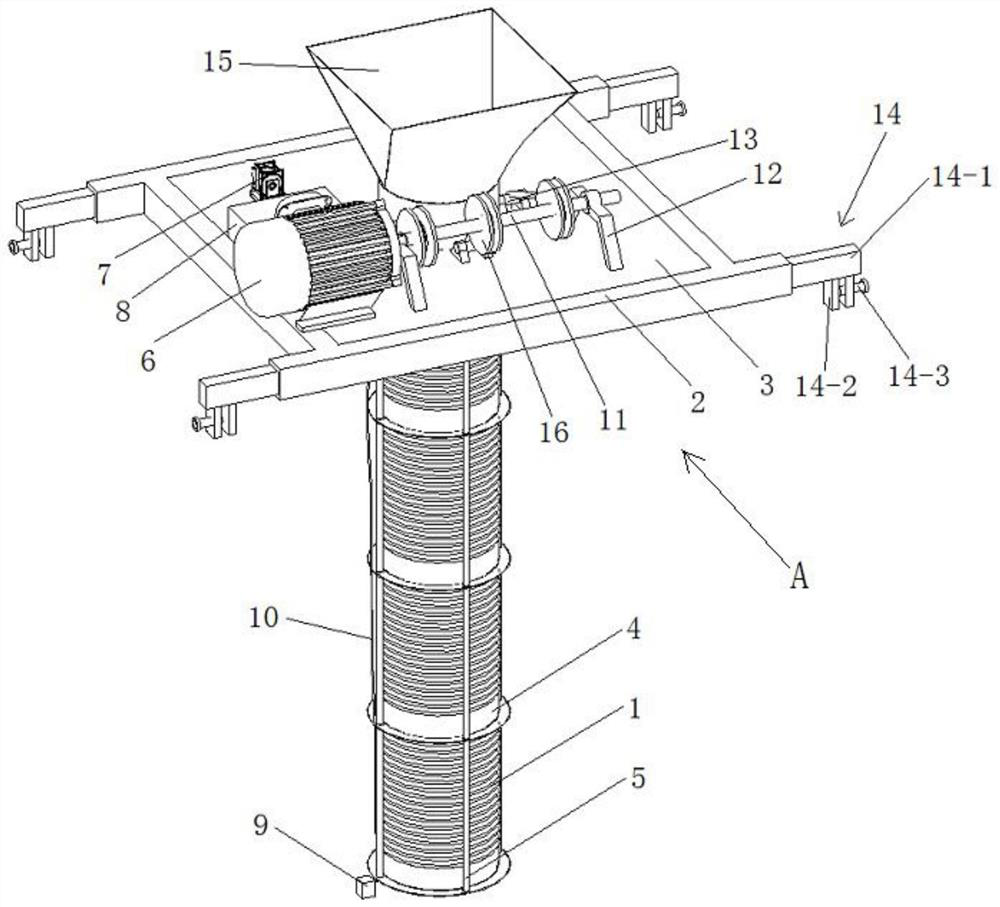

Continuous pouring equipment for tunnel special-shaped sewage ditch and using method

PendingCN114808615AReduce sizeEasy to operatePaving gutters/kerbsRoads maintainenceAgricultural engineeringSewage

The invention provides continuous pouring equipment for a tunnel special-shaped sewage ditch. The continuous pouring equipment comprises a vehicle body, a template, a hopper and a controller, a supporting frame and a lifting mechanism are connected to the trolley body, a hopper is fixedly connected to the supporting frame, walking wheels are fixedly connected to the lower side of the trolley body, an ejector rod and a pull rod are connected to one side of the trolley body, a sleeve is connected to the pull rod, and the sleeve is connected with a formwork. And the template is respectively provided with a feeding hole and is fixedly connected with a sleeve rod. The equipment is small in size, can be suitable for continuous pouring operation of the sewage ditch in a limited space, has the advantages of being easy to operate, time-saving, labor-saving, high in working efficiency and the like, and realizes the function of rolling and forming the sewage ditch at a time.

Owner:CHINA RAILWAY SIXTH GRP CO LTD +1

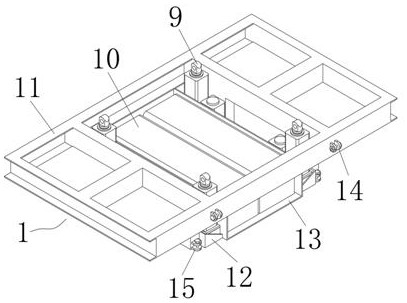

A crystallizer system for continuous casting of two-strand slabs

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Subway engineering inspection pit stand column concrete construction auxiliary device and using method

InactiveCN111535089AImprove consistencyImprove stabilityRailway track constructionVehicle frameArchitectural engineering

The invention discloses a subway engineering inspection pit stand column concrete construction auxiliary device and a using method, and relates to the technical field of concrete pouring tool equipment. The device comprises a hopper car and a funnel. The hopper car comprises a car frame, a hopper arranged on the car frame and used for storing a concrete slurry, and a walking assembly arranged below the car frame. At least two discharging openings capable of controlling opening and closing states are symmetrically arranged in a bottom surface of the hopper with the walking direction of the hopper as a symmetry center. The walking assembly comprises at least four pulleys which are arranged below the car frame and are matched with rails; and during usage, the funnel is mounted between an inspection pit stand column and the discharge openings and is connected with the inspection pit stand column and the discharge opening. The invention further discloses a using method of the device. The device is simple in structure and small in occupied area, and concrete construction of the subway engineering inspection pit stand column can be achieved without additionally arranging a concrete pumping-in device or a concrete storage device.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD +1

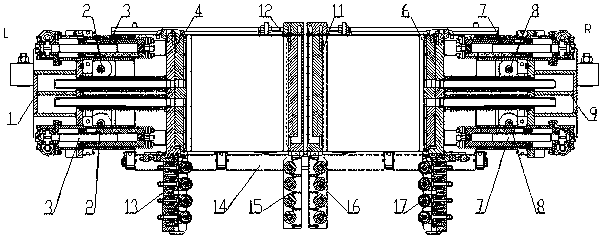

Crystallizer system for continuously casting double-flow plate blanks

The invention relates to a crystallizer system for continuously casting double-flow plate blanks. The crystallizer system comprises a frame assembly, wide-surface copper plate assemblies, narrow-surface copper plate assemblies, a middle insertion plate assembly, a width adjusting device, a clamping device and a foot roll assembly; the frame assembly comprises a left frame, a right frame ,an inner arc frame and an outer arc frame, and the left frame is respectively connected with the left side of the inner arc frame and the left side of the outer arc frame; the right frame is respectively connected with the right side of the inner arc frame and the right side of the outer arc frame; and the wide-surface copper plate assemblies comprise inner arc copper plate assemblies and outer arc copper plate assemblies which are provided with water channels, the outer arc copper plate assemblies are connected with the inner side surface of the outer arc frame, and the inner arc copper plate assemblies are connected with the inner side surface of the outer arc frame. The crystallizer system has the advantages that the crystallizer system is important composition equipment of a continuous casting machine for double-flow plate blanks, liquid steel is filled into two independent cavities of the crystallizer system, and the double-flow plate blanks are subjected to continuous casting via working procedures such as cooling, vibration stripping and throwing; and the crystallizer system is low in production cost, and resources are saved.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Concrete column pouring construction method based on telescopic string device

ActiveCN110206319BAdaptableEasy to use and flexibleBuilding material handlingFree fallingArchitectural engineering

The invention discloses a concrete column pouring construction method based on a telescopic tumbling barrel device. The telescopic tumbling barrel device comprises tumbling barrels, a positioning mechanism arranged at the tops of the tumbling barrels and used for positioning the tumbling barrels, and a control module arranged on the positioning mechanism and used for controlling the tumbling barrels to extend and retract. The concrete column casting construction method comprises the following steps that first, the telescopic tumbling barrel device is mounted; second, the tumbling barrels are wetted; third, concrete is poured; fourth, the telescopic tumbling barrel device is demounted; and fifth, later repouring is conducted. The concrete column pouring construction method is simple in step, construction is convenient and rapid, the tumbling barrels can be automatically controlled to extend and retract according to the real-time pouring height of the concrete, thus the free falling height of the concrete is flexibly controlled in the concrete pouring process, the phenomenon of concrete segregation is avoided effectively, meanwhile, the problems that at present, single sections of tumbling barrels need to be manually demounted one by one, the time and labor are consumed during operation, a machine is needed to be continuously matched with construction, and the concrete pouring efficiency is low are solved, practicability is high, and using and popularization are convenient.

Owner:SCEGC NO 5 CONSTRUCTION ENGINEERING GROUP COMPANYLTD

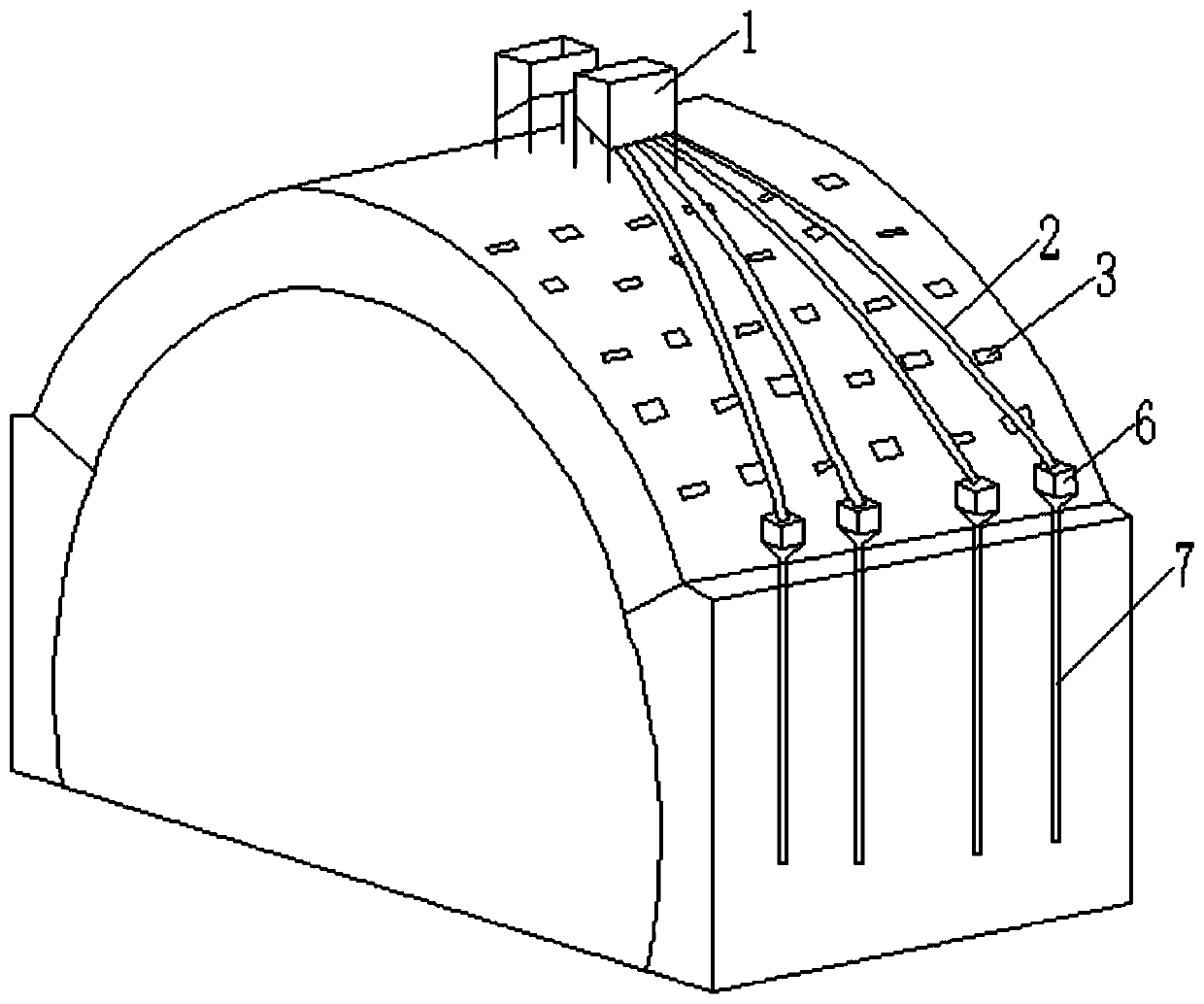

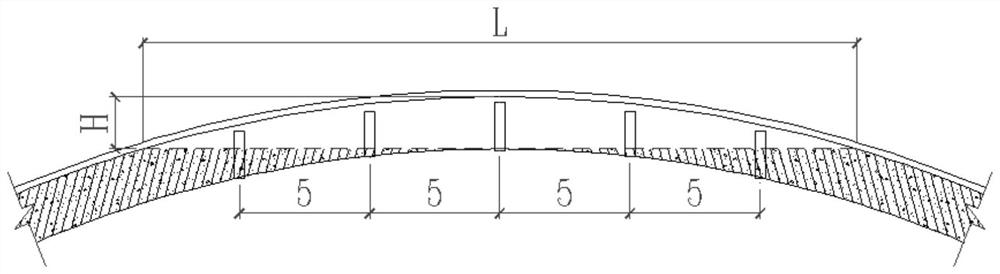

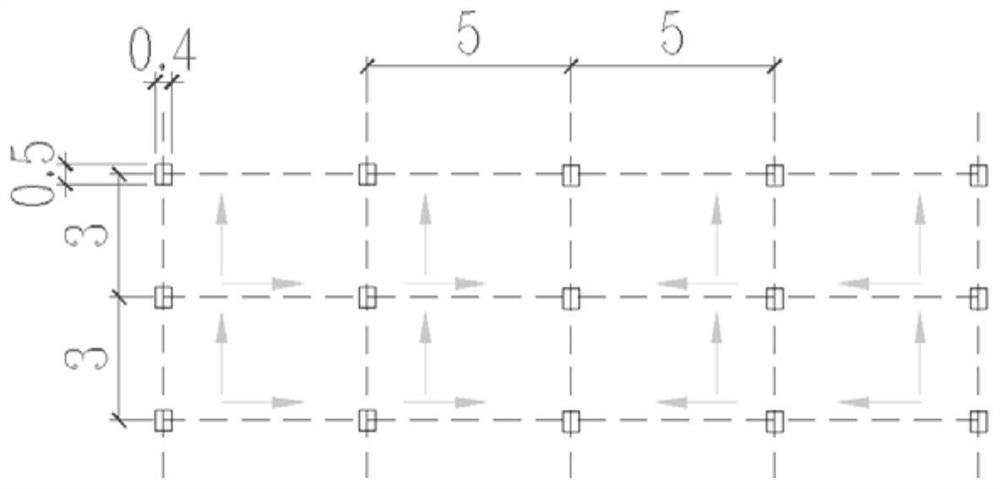

Continuous pouring method for preventing cracking of arch part of large-volume concrete of huge-span underground cavern

InactiveCN112227370AReduced peak heat of hydrationImprove project qualityArtificial islandsUnderwater structuresUnderground cavernArchitectural engineering

The invention discloses a continuous pouring method for preventing cracking of an arch part of large-volume concrete of a huge-span underground cavern. The continuous pouring method comprises the following steps that first, pouring pipes are arranged in the nearly horizontal section of a vault every 5+ / -0.5 m in the transverse direction and every 3+ / -0.5 m in the longitudinal direction, the distance between the pouring pipes and the vault is 20+ / -2 cm, and the height difference between the pouring pipes at the leftmost edge and the rightmost edge and the pouring pipe in the central line is 30-70 cm; second, self-compacting concrete is prepared; third, the side wall concrete on the left side and the right side of the huge-span underground cavern is poured firstly, and the longitudinal length of each time of concrete pouring is 10+ / -0.5 m; fourth, the self-compacting concrete is adopted for synchronously pouring arch shoulder sections on the left side and the right side of the arch part;and fifth, the self-compacting concrete is adopted for pouring the nearly horizontal section of the vault, symmetrical pouring is conducted from the edge to the middle in the transverse direction, sequential pouring is conducted from inside to outside in the longitudinal direction, and the pouring pipes are reserved in the concrete after pouring and not taken out. The hydration heat peak value ofthe concrete in the nearly horizontal section of the vault is decreased, so that cracking is avoided, and the engineering quality and the construction efficiency of the huge-span underground cavern are improved.

Owner:中铁隧道集团一处有限公司 +1

Upper mould casting head device of signal connector mould device

PendingCN110370536ARealize continuous pouringCoatingsEngineeringElectrical and Electronics engineering

The invention discloses an upper mould casting head device of a signal connector mould device. The upper mould casting head device comprises an upper main connecting block, wherein an upper mounting connecting block is fixedly arranged on the top surface of the upper main connecting block; a plurality of upper moulds are mounted on the bottom surface of the upper main connecting block; a casting main component is nested in a mounting groove in the upper mounting connecting block, and the bottom ends of branch casting pipes of the casting main component sequentially extend out of the bottom surface of the upper mounting connecting block and the bottom surface of the upper main connecting block and are inserted into casting through holes in the middles of the upper moulds. Continuous castingis realized as the casting main component adopting the plurality of branch casting pipes simultaneously communicates with the casting through holes of the plurality of upper moulds.

Owner:DONGGUAN DINGTONG PRECISION METAL CO LTD

Production method of high-cleanliness high-titanium low-carbon steel

The invention relates to a production method of high-cleanliness high-titanium low-carbon steel, belonging to the technical field of iron and steel metallurgy. The technical problem to be solved by the invention is that when the titanium content is high, the steel quality becomes poor, the cleanliness is low, and the quality of the final product produced is low. The invention provides a production method of high-cleanliness high-titanium low-carbon steel, which is produced according to the converter-RH-argon-blowing-slab continuous casting process flow, the end point of the converter is controlled, the converter is tapped, and the RH deoxidizes and alloys the molten steel step by step. During the tapping process, high-titanium and low-carbon steel refining slag is added to the ladle to make slag and the ladle slag composition is controlled. Mold slag is used in the pouring process, and the titanium content in the steel is 0.15‑0.8% by mass fraction. The invention can realize the smooth pouring of high-titanium low-carbon steel, and auxiliary materials such as ladle slag, tundish covering agent and mold slag have a good ability to absorb non-metallic inclusions, and the performance can still remain stable after absorbing a large number of inclusions. The cleanliness of the molten steel is high, and the quality of the poured slab is good.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD +1

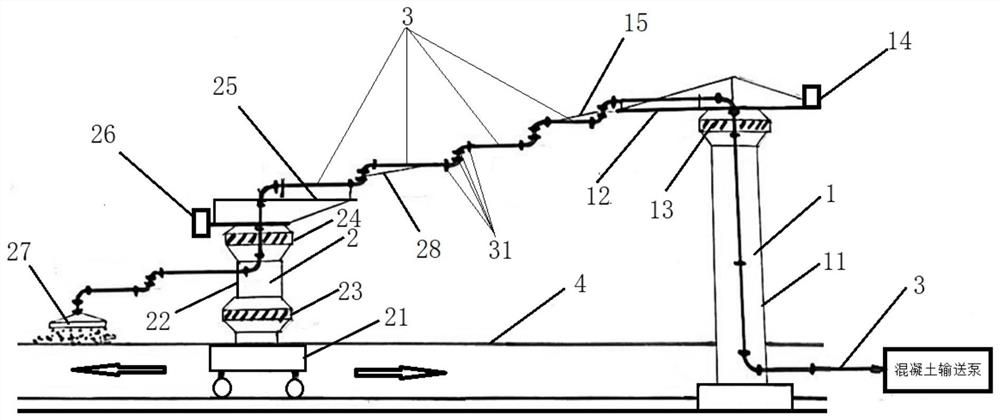

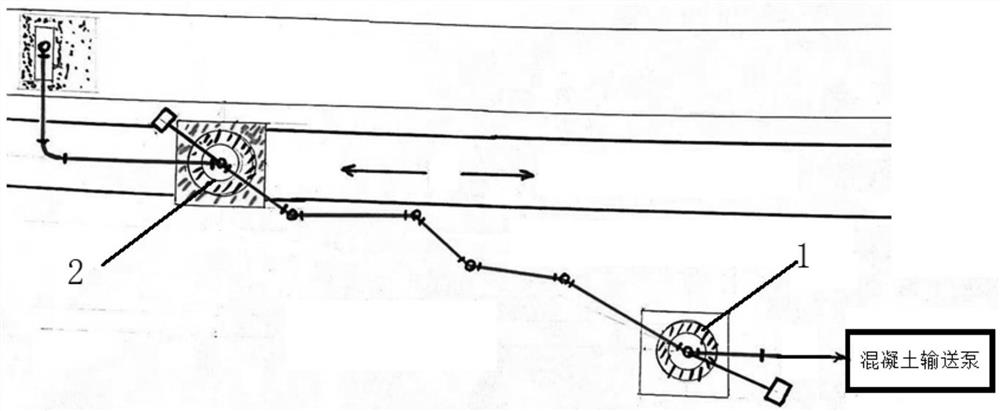

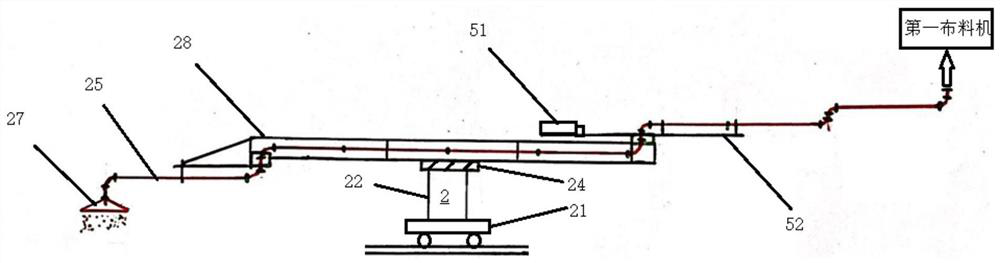

Concrete long distance linear distribution system and method

ActiveCN112917661BImprove continuityMoving in a straight line at a constant speedFeeding arrangmentsClassical mechanicsStructural engineering

A long-distance linear distribution system for concrete is provided, comprising: a first distribution machine, which is fixedly arranged on site and includes a rotatable first arm and a second arm; and includes a rotatable third arm rod and a fourth arm rod; and a concrete conveying pipe, including a plurality of sub conveying pipes hinged with each other through joints, the first end of the concrete conveying pipe is connected to the concrete conveying pump, and the second end is connected to the pouring nozzle; Wherein, the plurality of sub-conveying pipes between the uprights of the first distributing machine and the uprights of the second distributing machine can be changed between an extended state and a folded state with the reciprocating running of the second distributing machine. The distribution port can move in a straight line at a constant speed, and the pouring of the components can achieve precise and continuous operation at the same time.

Owner:广东康酷瑞装配式建筑有限公司

Production method of high titanium steel

ActiveCN111593172BReduce burning lossNo crackProcess efficiency improvementRefining (metallurgy)Slag

The invention relates to a production method of high-titanium steel, belonging to the technical field of iron and steel metallurgy. The technical problem to be solved by the present invention is that when the existing high-titanium steel is produced by the "converter-refining-continuous casting" process flow, there are serious breakouts and continuous casting cannot be realized, and the billet has serious defects. The invention provides a production method of high-titanium steel, which is produced according to the converter-LF-RH-slab continuous casting process flow, the end point of the converter is controlled, and the molten steel is deoxidized and alloyed in steps of converter tapping, LF, and RH, and converter tapping, LF Add high-titanium and low-carbon steel refining slag into the ladle to make slag and control the composition of the ladle slag. The pouring process uses mold slag, and the titanium content in the steel is 0.1-0.8% by mass fraction. The invention realizes continuous pouring for more than 120 minutes, and the poured billet has no cracks on the surface, good internal quality, and no central cracks and middle cracks.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

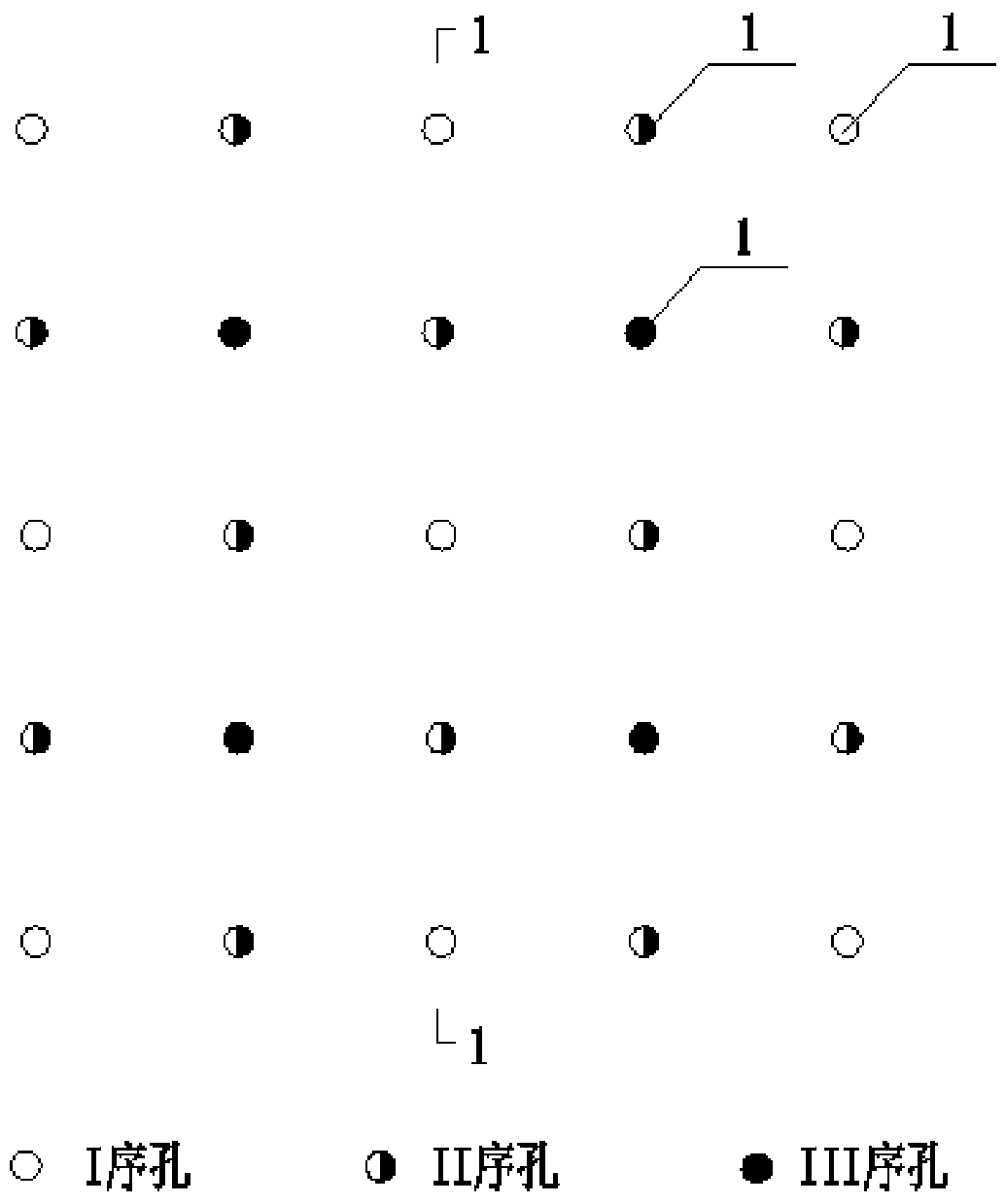

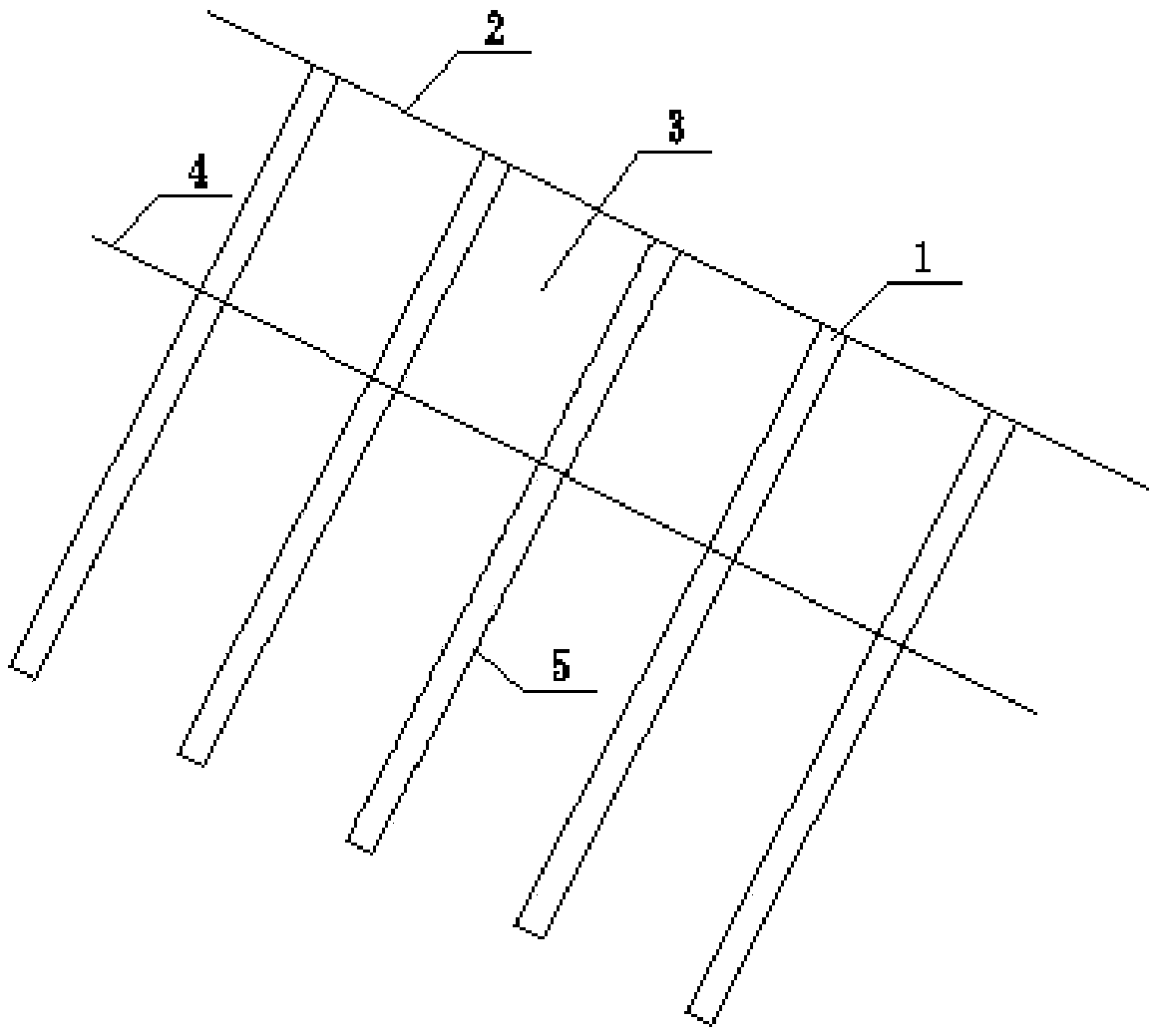

A construction method of rock cover heavy consolidation grouting

ActiveCN106917409BRealize continuous pouringResolve conflicts that affect and interfere with each otherSoil preservationRock bodyBuilding construction

The invention provides a rock cover-weighted consolidation grouting construction method, and belongs to a dam foundation consolidation grouting method for hydraulic and hydroelectric engineering. When a dam foundation is excavated, a rock layer with the thickness being 5 m is reserved above the elevation of a foundation surface to be used as a rock cover weight, consolidation grouting is conducted, and the direction of grouting holes is perpendicular to the foundation surface; one-time pore-forming grouting is conducted on the rock cover weight layer, the grouting pressure is not larger than 0.5 MPa, segmented hole drilling and segmented grouting are conducted on the rock mass below the cover weight, the grouting pressure reaches 3 MPa, excavating and stripping are conducted on the rock cover weight layer after grouting ends and passes examination, shallow-layer quality inspection is then conducted on the foundation surface, and draft pipe grouting is conducted on unqualified parts. By means of the consolidation grouting construction method, the consolidation grouting time is brought forward to the dam foundation excavation stage from the dam foundation concrete pouring period, the dam foundation consolidation grouting procedure and the concrete pouring procedure completely make no contact, and dam foundation concrete continuous pouring is achieved. The consolidation grouting construction method has the beneficial effects of being high in construction speed, high in efficiency, good in grouting effect and the like, and the conflict that the dam foundation consolidation grouting construction for hydraulic and hydroelectric engineering and concrete pouring interfere with each other is eliminated.

Owner:SINOHYDRO ENG BUREAU 4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com