Rotating device for casting base pad

A rotary, rotating shaft technology, applied in ingot workshop, foundry workshop, casting equipment, etc., can solve the problem of not being able to mass production, achieve the effect of uniform bottom pad, reduce production cost and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

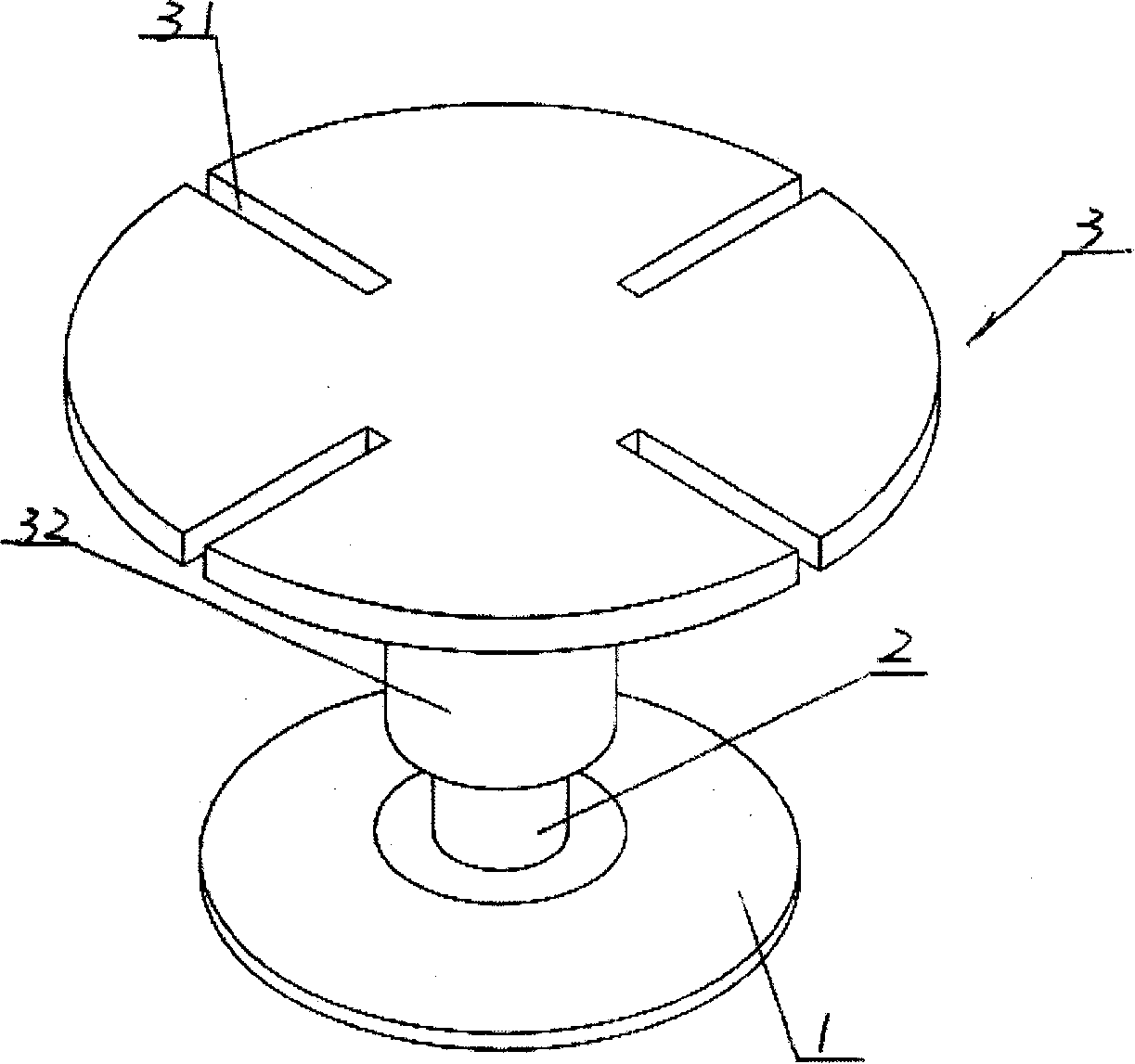

[0009] see figure 1 , which shows the overall structure of the appearance of an embodiment of the rotary casting base pad device proposed by the present invention. The device includes a base 1, a rotating shaft 2 installed in the middle area of the base 1, and a support member installed on the top of the rotating shaft 2. The support member can be made of a disc-shaped part 3, four slots 31 for fixing the mold are arranged on two mutually perpendicular diameter directions of the disc-shaped part 3, and the length of each slot 31 is less than that of the disc-shaped part. The radius of piece 3. The bottom of the central part of the disc-shaped part 3 is provided with a socket 32, and the end of the disc-shaped part 3 is connected with the end of the rotating shaft 2 through the plug-in sleeve 32. When the rotating shaft 2 rotates, the disc-shaped part 3 can be driven to rotate. .

[0010] When in use, the mold is placed on the upper surface of the disc-shaped part 3, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com