Continuous pouring equipment for tunnel special-shaped sewage ditch and using method

A sewage ditch and special-shaped technology, applied in roads, buildings, roads, etc., can solve problems such as poor line shape of curve segments, difficulty in sewage discharge, artificial plastering cross-section size, longitudinal slope at the bottom of the ditch does not meet the design requirements, etc., to achieve small size and convenient Construction, avoiding the effect of difficulty in moving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

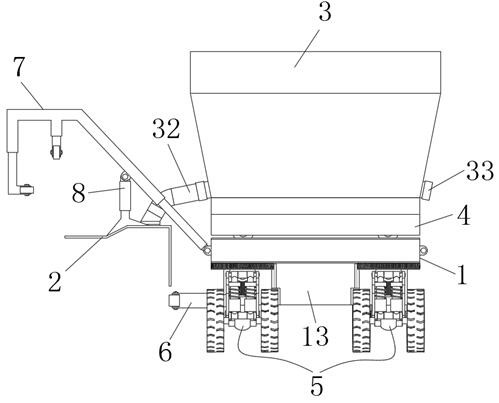

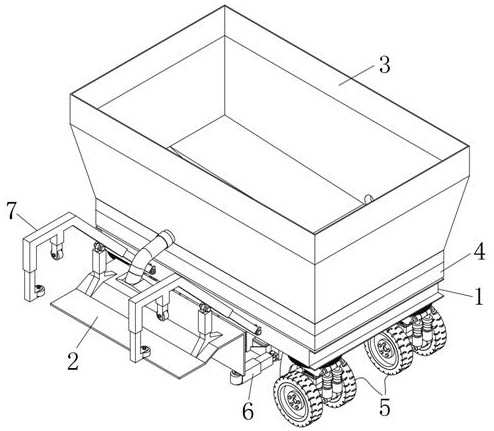

[0056] like Figure 1-12 As shown, a continuous pouring equipment for tunnel special-shaped sewage ditch includes a car body 1, a formwork 2, a hopper 3 and a controller;

[0057] The car body 1 is connected with a support frame 4 and a lifting mechanism, the support frame 4 is fixedly connected with the hopper 3, the lower side of the car body 1 is fixedly connected with a walking wheel, and one side of the car body 1 is respectively connected with a top rod 6 and a pull rod 7, the pull rod 7 is connected with a sleeve 8, and the sleeve 8 is connected with the template 2; the template 2 is respectively provided with a feeding port 21 and a sleeve rod 22 is fixedly connected; in the case of insufficient rolling pressure of the template 2 during casting and molding, A corresponding counterweight can be placed on the template 2 to roll out the required shaped sewage ditch casting body.

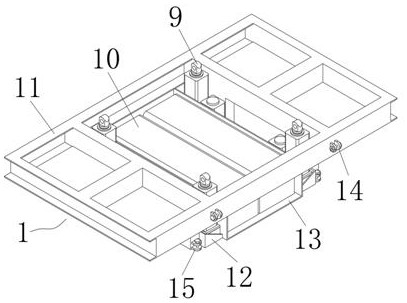

[0058] Preferably, the vehicle body 1 further includes a vehicle frame 11, a battery box 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com