Automatic model board trolley for bridge crash barrier

A technology of anti-collision guardrails and formwork trolleys, which is applied to bridges, bridge construction, bridge parts, etc., can solve the problems of long installation time, water seepage in the structure, and many reinforcement components, so as to reduce labor intensity, improve utilization rate, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

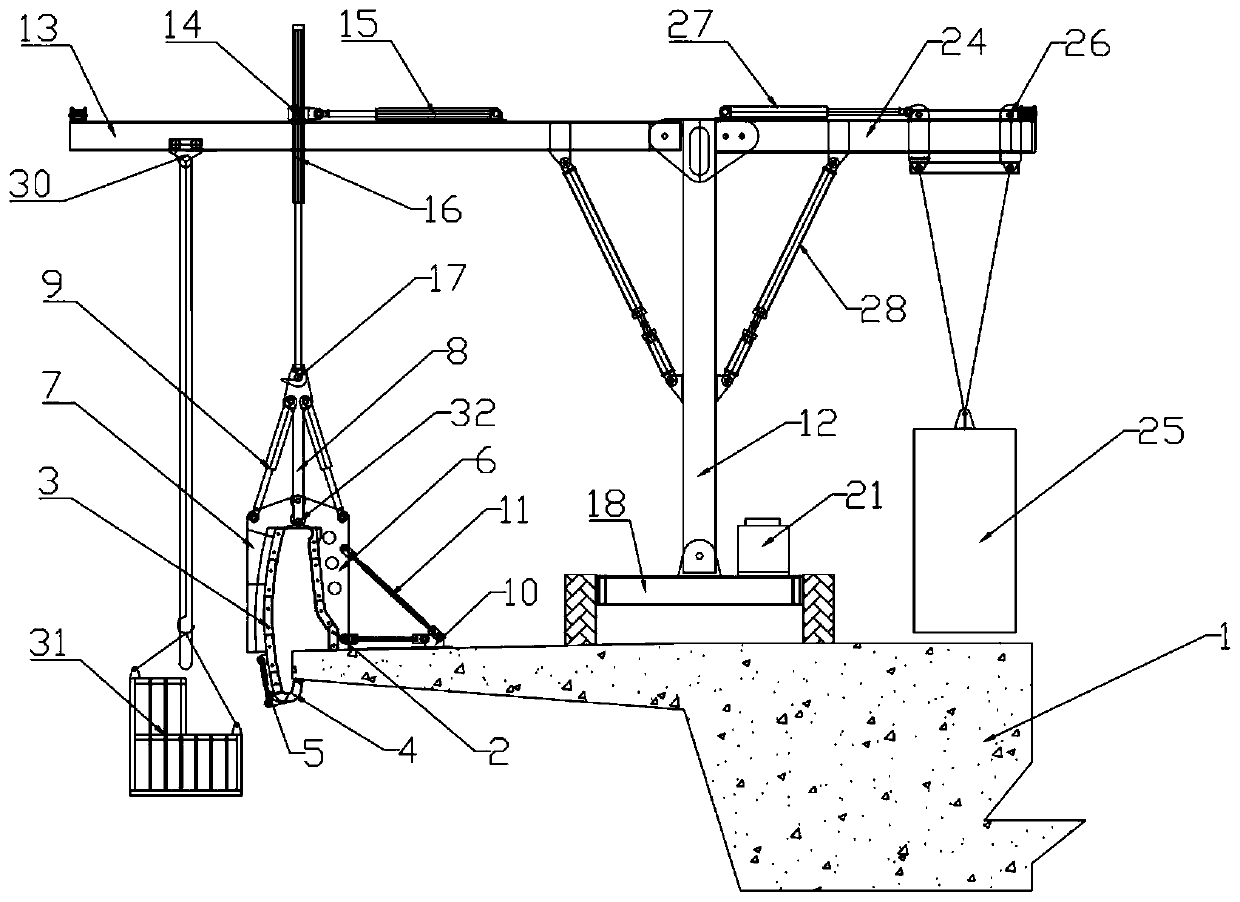

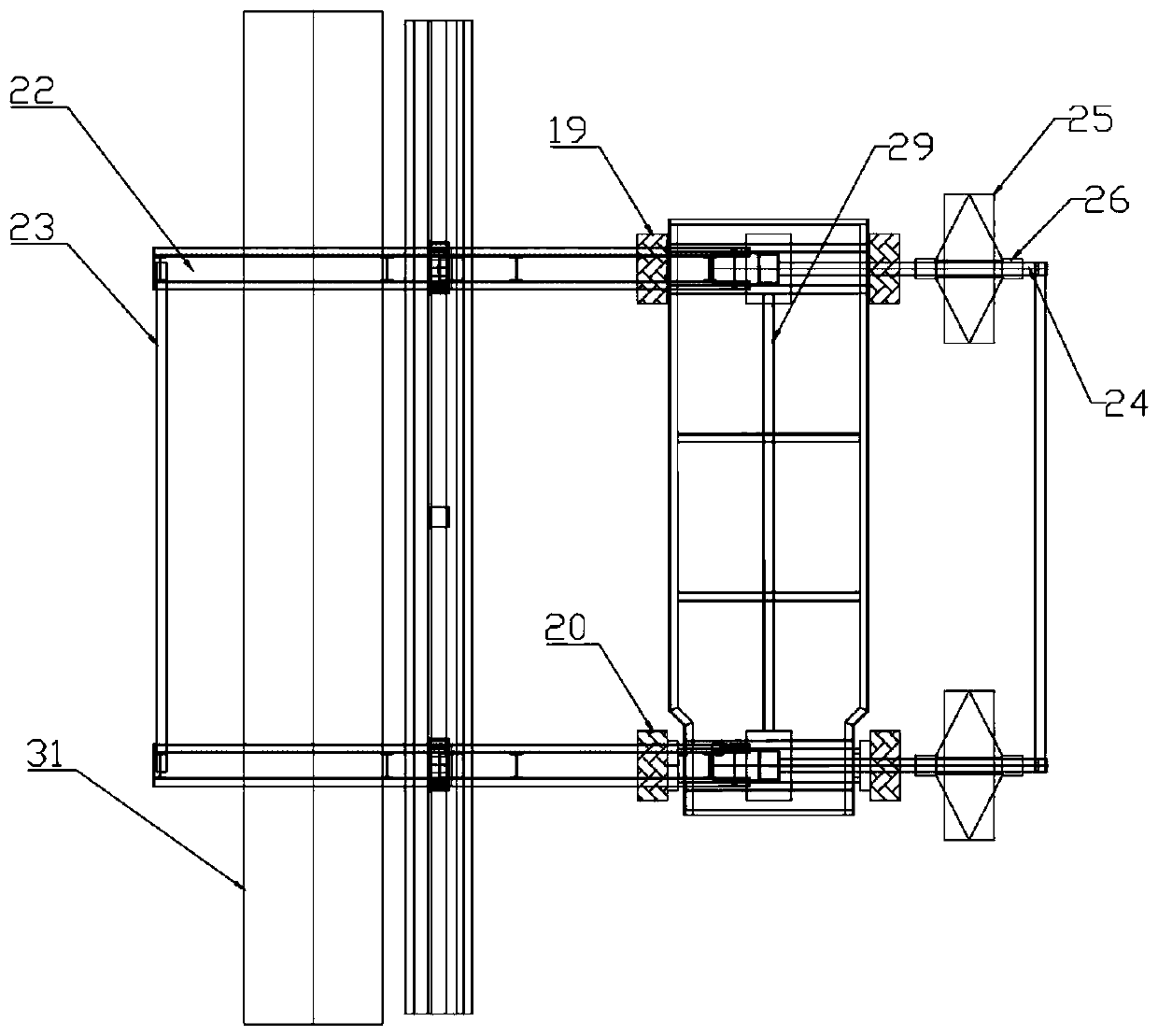

[0027] refer to Figure 1-2 , an automated formwork trolley for the anti-collision guardrail of an elevated bridge, comprising a formwork, at least two sets of mold opening and closing mechanisms arranged along the length direction of the formwork, and a lifting device for lifting the mold opening and closing mechanisms.

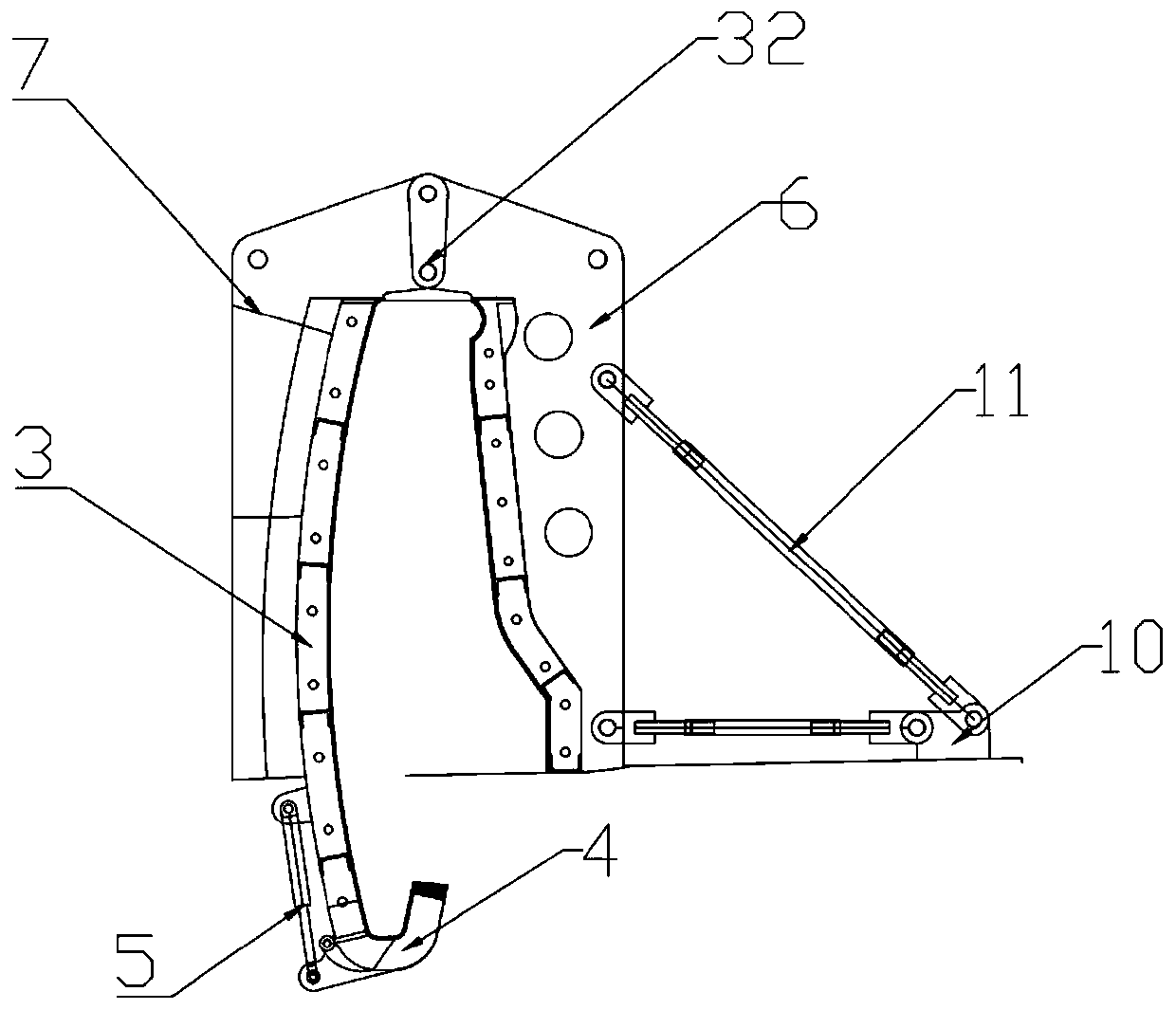

[0028] The formwork is a set of stainless steel formwork with a thickness of 8mm, and a 10m section of integral steel formwork forms a self-contained system, including the inner formwork 2 of the anti-collision guardrail set on the cast-in-place box girder 1 and the outer formwork of the anti-collision guardrail set outside the cast-in-place box girder 1 Formwork 3, under the cast-in-place box girder 1, there is a droplet eave formwork 4 hinged with the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com