Concrete long distance linear distribution system and method

A cloth system, long-distance technology, applied in the direction of manufacturing tools, supply devices, etc., can solve the problems of insufficient cloth accuracy, small cloth radius, low output, etc., to achieve the effect of precise and continuous operation, and increase the linear distance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

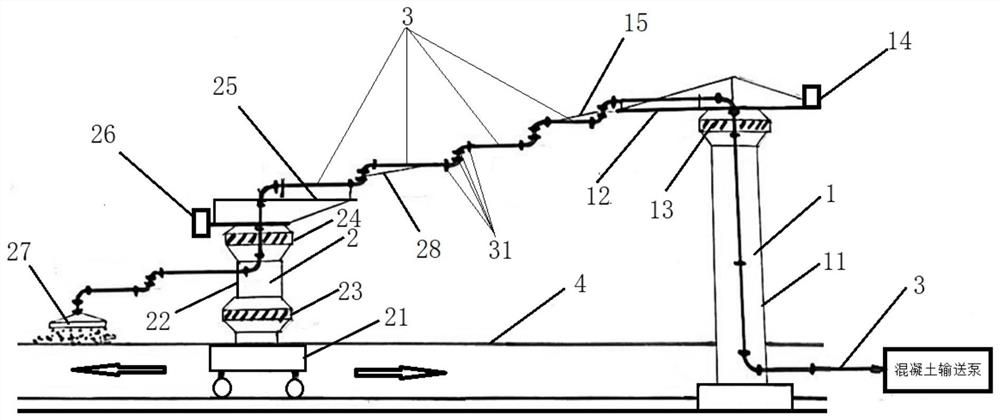

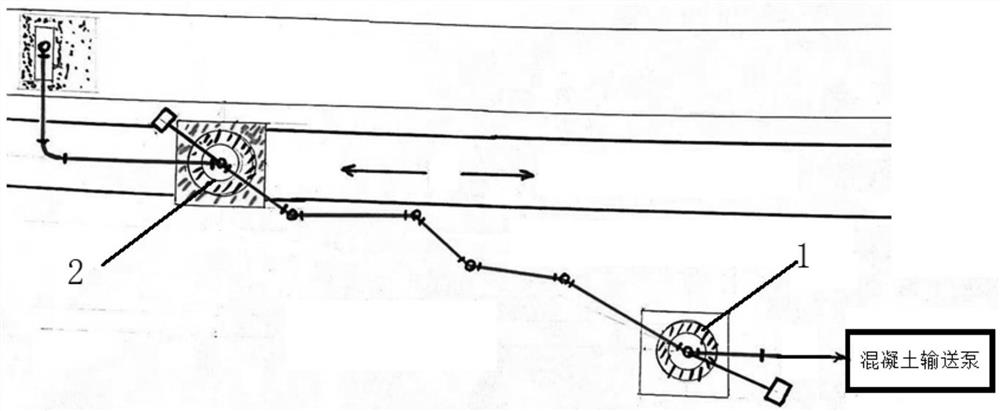

[0044] see Figure 1-2 , 5-6, according to a preferred embodiment of the present invention, there is provided a concrete long-distance linear distribution system, which includes:

[0045] The first distributing machine 1 is fixed on the site and includes a rotatable first arm 12 and a second arm 15;

[0046] The second distributing machine 2, which can reciprocate straightly along the first direction and includes a rotatable third arm 25 and a fourth arm 28; and

[0047]The concrete conveying pipe 3 includes a plurality of sub-conveying pipes hinged with each other through the joint 31, the first end of the concrete conveying pipe 3 ( figure 1 The right end in the middle) is connected to the concrete pump, and the second end ( figure 1 The left end in the middle) is connected to the pouring nozzle 27;

[0048] The concrete conveying pipe 3 extends from the first end to the bottom of the first distributor 1, the top of the first distributor 1, the first boom 12 and the secon...

Embodiment approach

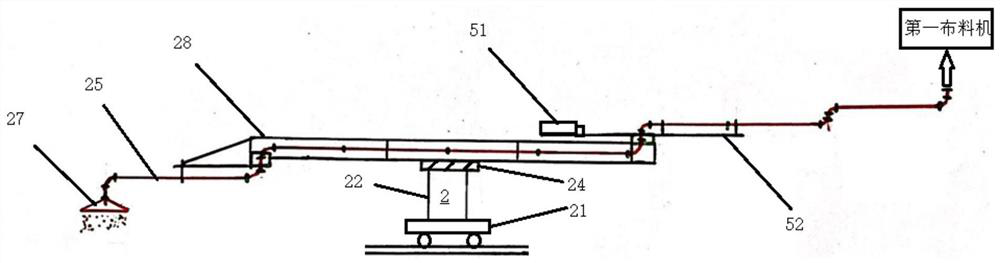

[0056] According to another preferred embodiment of the present invention, a first turning mechanism 13 is provided on the upper part of the first distributing machine 1 . The second distributing machine 2 includes: a walking mechanism 21 arranged at the bottom; a column 22, which is arranged on the walking mechanism 21; a second rotating mechanism 24, which is arranged on the upper part of the column 22; and a third rotating mechanism 23, which is arranged on the The lower part of the upright column 22 ; the third arm rod 25 is disposed on the top of the upright column 22 ; and the fourth arm rod 28 is rotatably hinged to the second end of the third arm rod 25 . Preferably, the third arm rod 25 and the fourth arm rod 24 are arranged upside down.

[0057] It can be understood that the booms (the first and second booms) of the existing stationary spreader 1 are defined as normal settings, on the contrary, see figure 1 , the third arm 25 and the fourth arm 24 of the second dist...

Embodiment 2

[0074] According to a preferred embodiment of the present invention, see figure 1 , provides a kind of walking type cloth machine 2, it is characterized in that including:

[0075] A walking machine arranged at the bottom, 21;

[0076] The upright column 22 is arranged on the walking mechanism 21;

[0077] Two swivel devices 23, 24 are respectively arranged on the upper and lower parts of the upright column 22;

[0078] The first arm rod 25 is arranged on the upright column 22 and has a first end and a second end, and the first end is provided with a counterweight 26;

[0079] The second arm rod 28 is rotatably hinged to the two ends of the first walking type distributing machine of the first arm rod 25; and

[0080]The concrete delivery pipe 3 has an inlet and an outlet, the inlet is located near the second end of the second arm 28 (the end away from the first arm 25 ) and at a first height, and the outlet is connected to the pouring nozzle 27 and at a second height, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com