Free face transverse slip form concrete pouring device

A technology for pouring concrete and air-facing surfaces. It is applied in construction, erection/assembly of bridges, bridges, etc. It can solve the problems of increasing project cost, pouring concrete without bracket erection, increasing construction period, etc., and achieves the effect of continuous pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

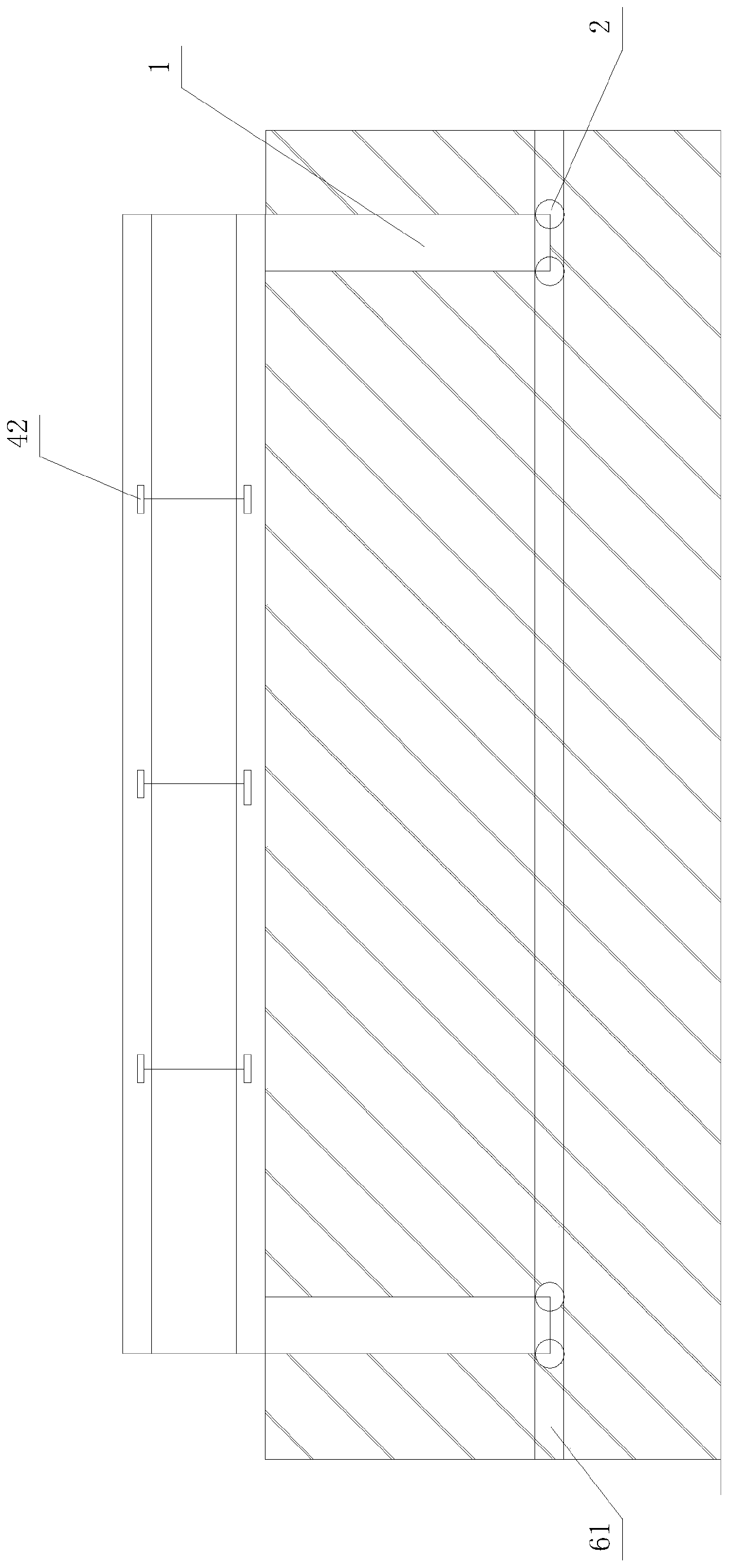

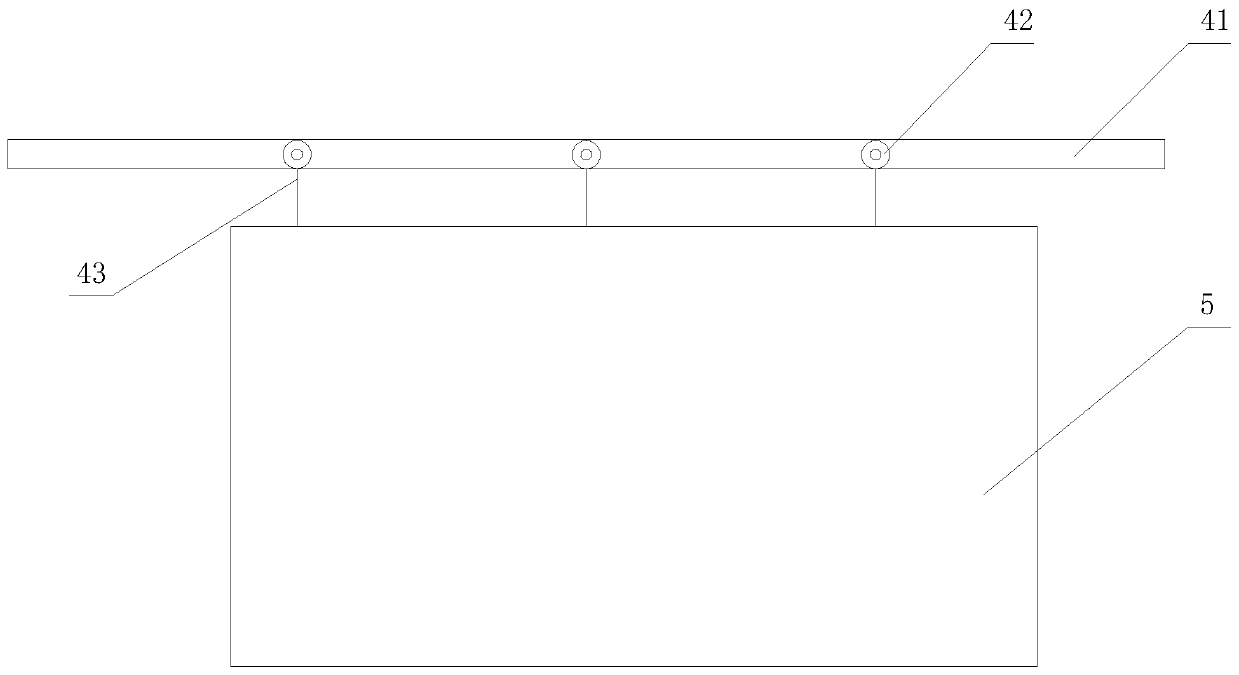

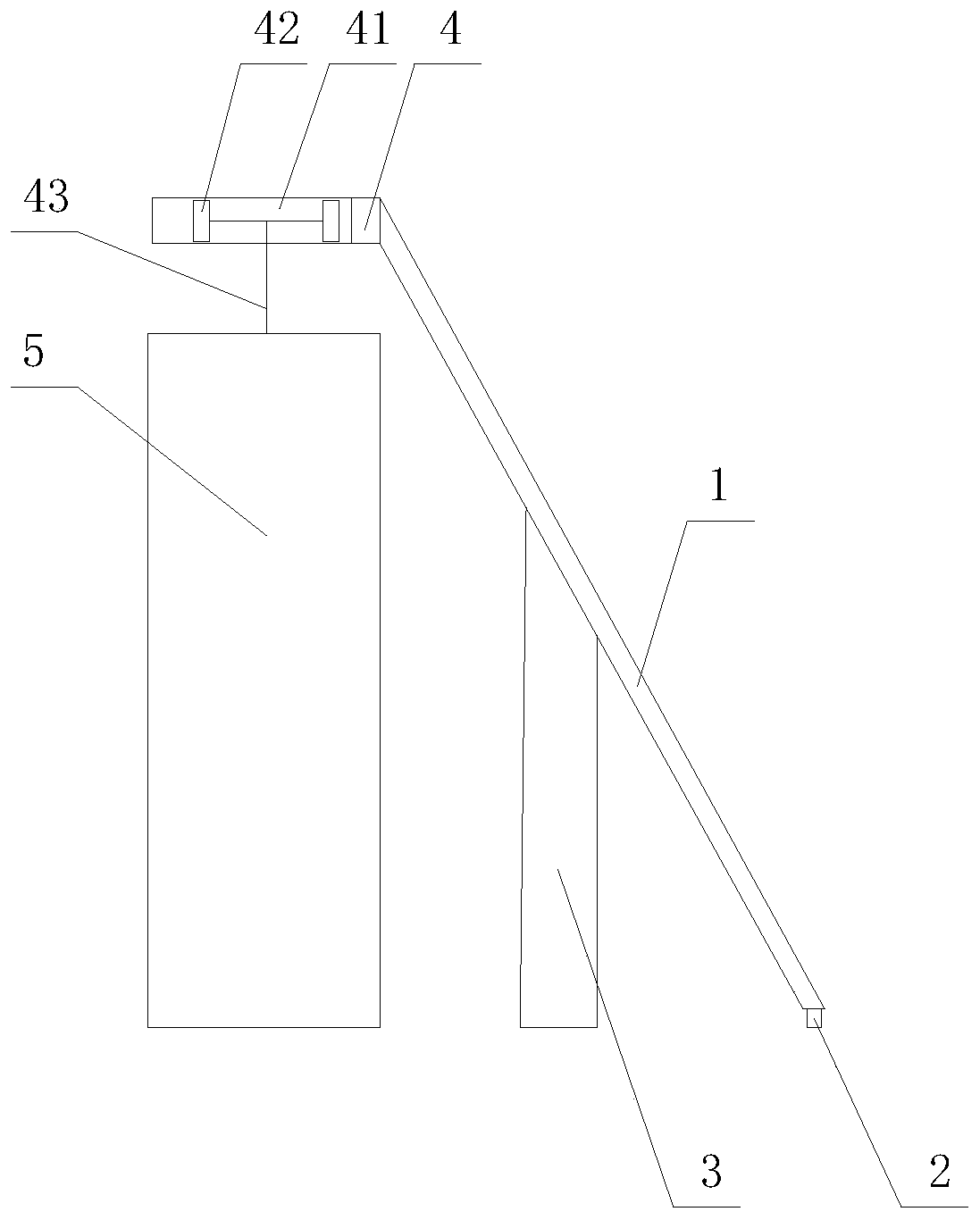

[0019] A device for pouring concrete with a horizontal sliding form on the air surface, comprising two fixing devices 1, the lower ends of the fixing devices 1 are fixedly connected with a first pulley 2, and the first pulley 2 moves on a first guide rail 61, and the The quantity of the first pulley 2 is 4, and each fixing device 1 is provided with 2 first pulleys 2, and the middle part of the fixing device 1 is connected with the steel box girder deck 3, and the upper end of the fixing device 1 is fixedly connected with Guide rail part 4, described guide rail part 4 is installed horizontally, and described guide rail part 4 is fixedly connected with second guide rail 41, and described second guide rail 41 is movably connected with 3 second pulleys 42, and the center of described second pulley 42 The shaft is fixedly connected with a bracket, and the bracket is fixedly connected with a steel rope 43 , and the lower end of the steel rope 43 is fixedly connected with a pin, and t...

Embodiment 2

[0022] The difference from Embodiment 1 is that there are six second pulleys (42).

Embodiment 3

[0024] The difference from Embodiment 1 is that there are four second pulleys (42).

[0025] It can be known that the technical effect of the technical solution adopted by the present invention is through the above-mentioned specific implementation manners: it has avoided the influence of the traditional construction technology on the normal traffic flow during the construction of the urban overpass bridge construction project; The method of pouring concrete by lifting the formwork by a crane results in high cost of mechanical shifts; this device is used in conjunction with the first pulley and the second pulley to complete the continuous pouring of concrete on the air surface, and the process of disassembling the formwork is simple. The construction period is short.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com