A construction method of rock cover heavy consolidation grouting

A technology of consolidation grouting and construction method, which is applied in the fields of infrastructure engineering, construction, soil protection, etc., can solve the problems of mutual influence and mutual interference with the surface grouting effect and separation of the foundation surface, so as to save cleaning costs and eliminate concrete. damage and quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

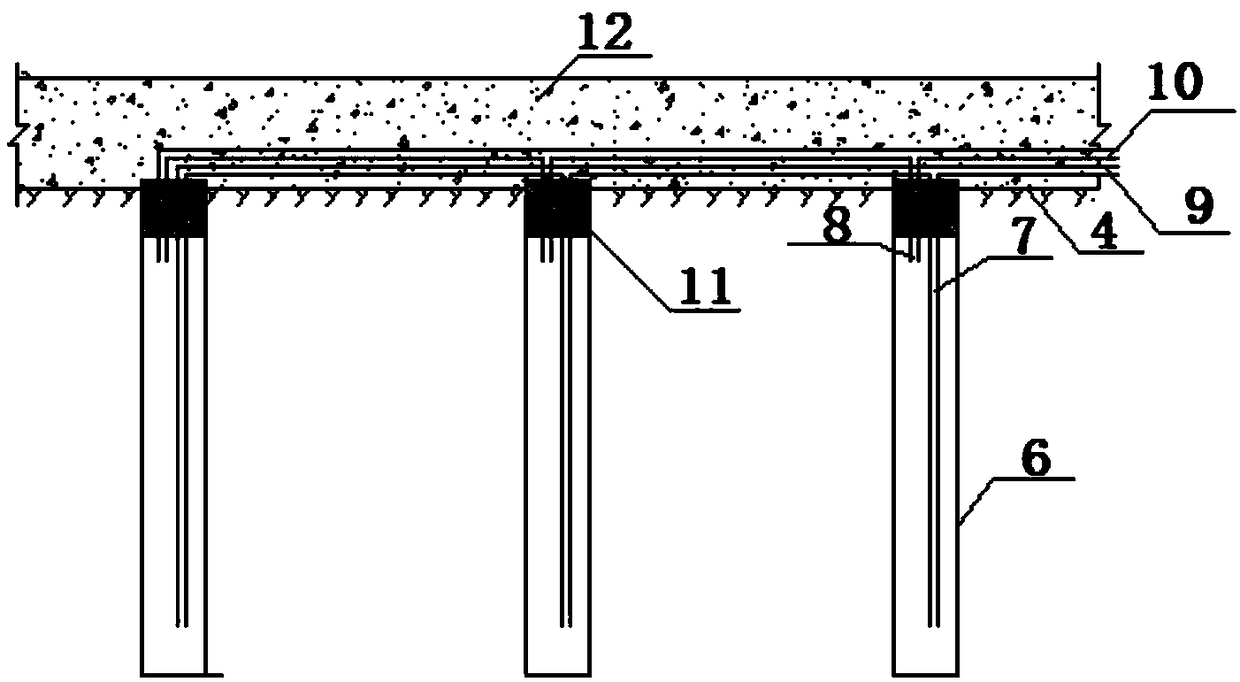

[0022] When the dam foundation is excavated, a 5m rock protection layer is reserved on the foundation surface to form a rock cover layer, and consolidation grouting operations are performed on the rock cover layer.

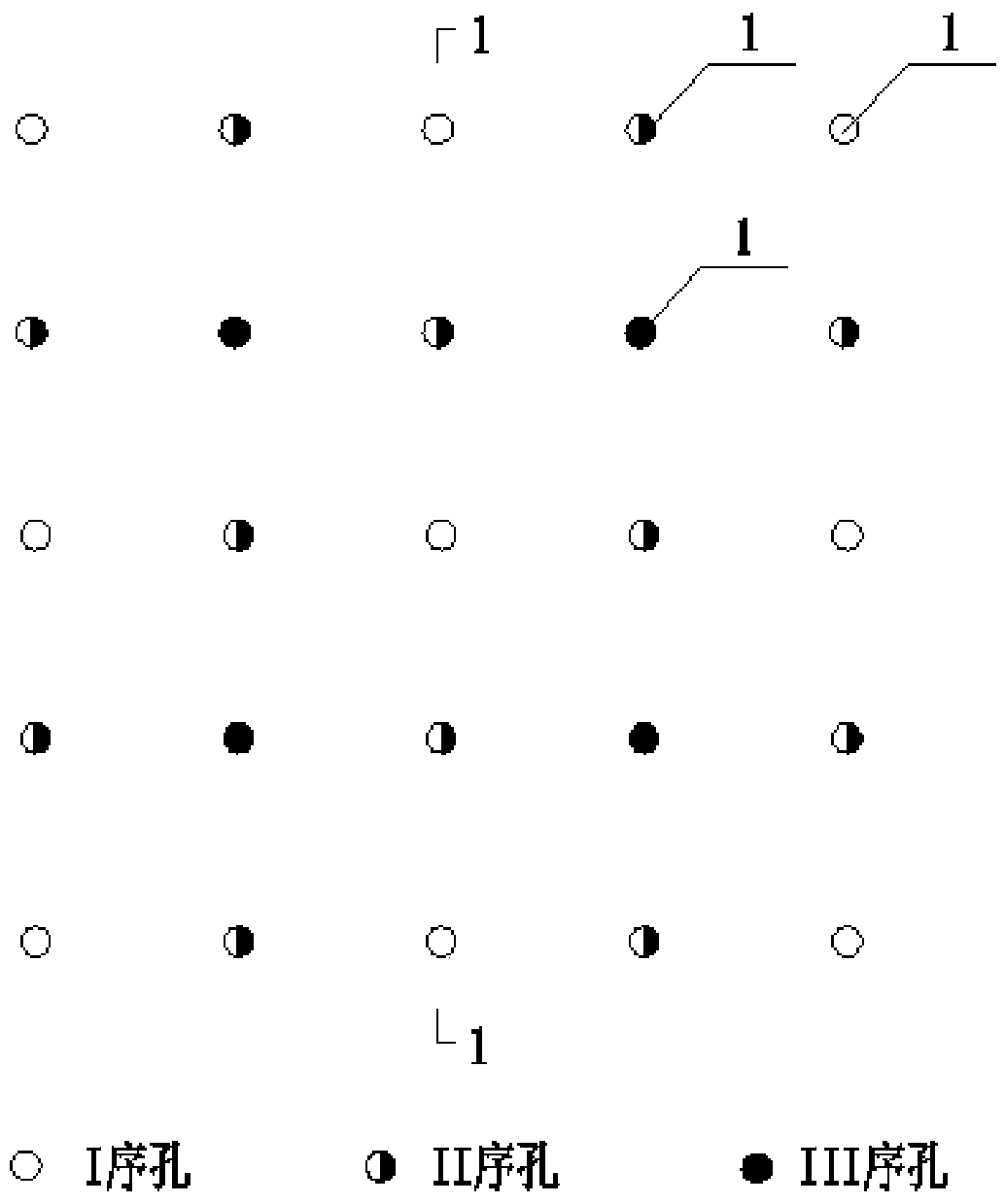

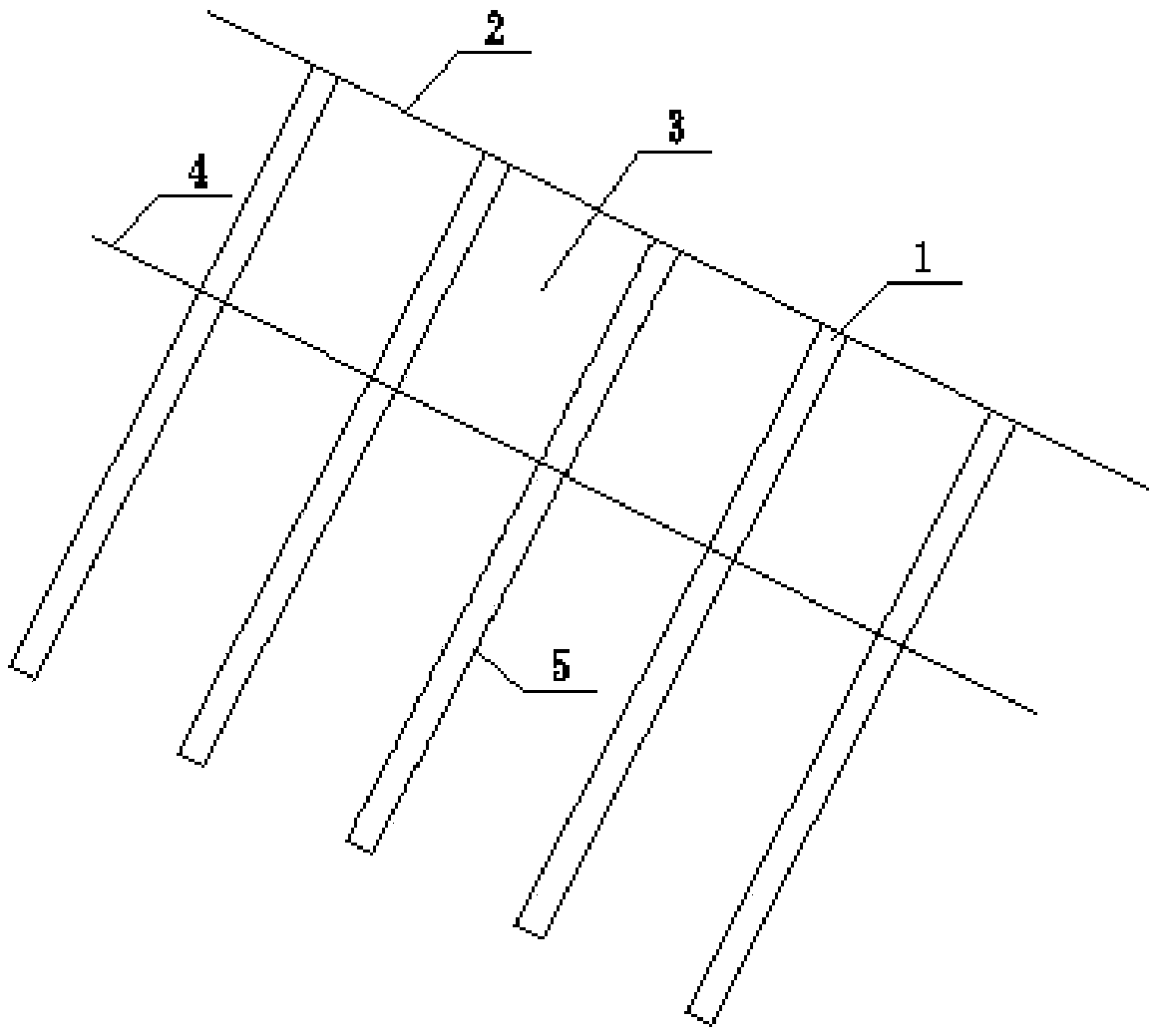

[0023] Arrange the consolidation grouting hole position according to the design drawing on the rock cover heavy layer, and carry out drilling and grouting according to the hole position, and the drilling direction is vertical to build the foundation surface; the rock cover heavy layer is grouted at low pressure, one-time hole-forming grouting without segmentation, and the foundation surface is built The following rock masses are grouted under high pressure and drilled in sections and grouted in sections.

[0024] After the rock cap heavy consolidation grouting quality inspection is qualified, measures such as shock absorption and loosening are taken to excavate and strip the rock cap heavy layer to form the foundation surface.

[0025] After the foundation surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com