Continuous pouring method for preventing cracking of arch part of large-volume concrete of huge-span underground cavern

A large-volume concrete and concrete technology, which is applied in the field of large-volume concrete pouring in giant-span underground caverns, can solve the problems of difficult concrete pouring and cracks, and achieve the effects of improving construction efficiency, avoiding cracks, and ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

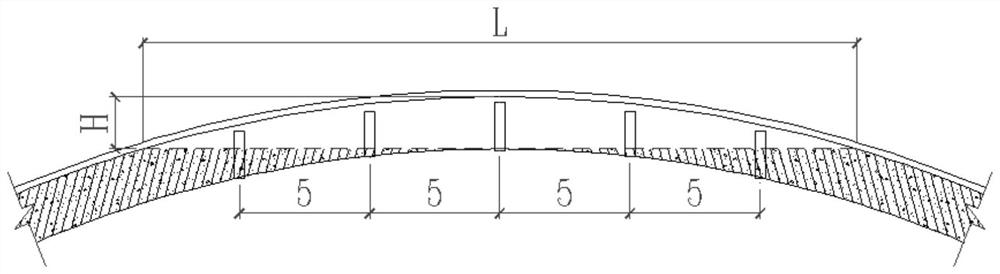

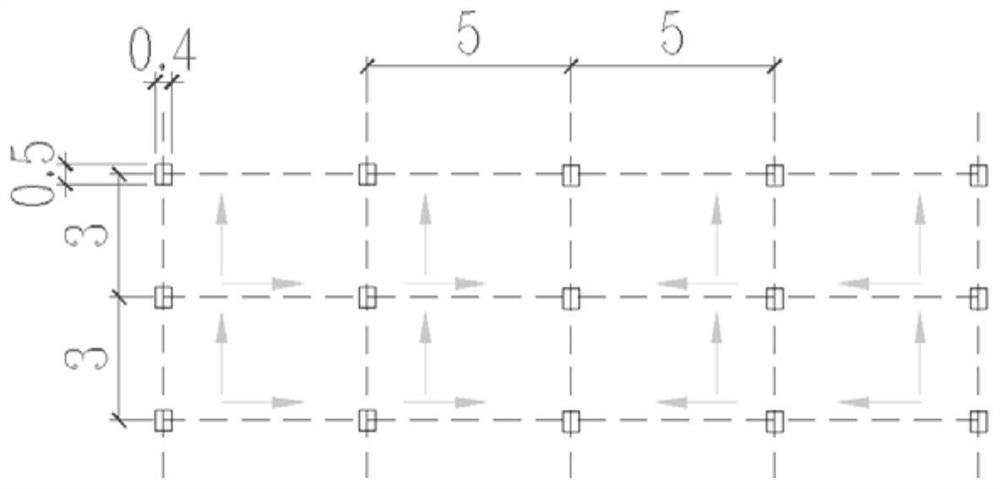

[0023] Usually, a huge-span underground cavern is divided into an arch and a side wall; the arch is arc-shaped and consists of a near-horizontal section of the vault and spandrel sections symmetrically arranged on the left and right sides of the near-horizontal section of the vault. The transverse span L of the near-horizontal section of the vault is no less than 30m, so it is called a "giant-span underground cavern". Due to the large transverse span L of the near-horizontal section of the vault of the giant-span underground cavern, the corresponding lining steel bars are densely arranged, and it is extremely difficult to feed and vibrate. In the process of self-compacting concrete flowing and filling automatically, a large number of stones will be dense The coarse aggregate in the concrete is unevenly distributed due to the reinforcement being stuck. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com