Novel cement hydration and thermal control material and preparation method thereof

A cement hydration and thermal control technology, applied in the field of concrete admixtures, can solve the problems of inability to add small molecular sugar units, low esterification efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

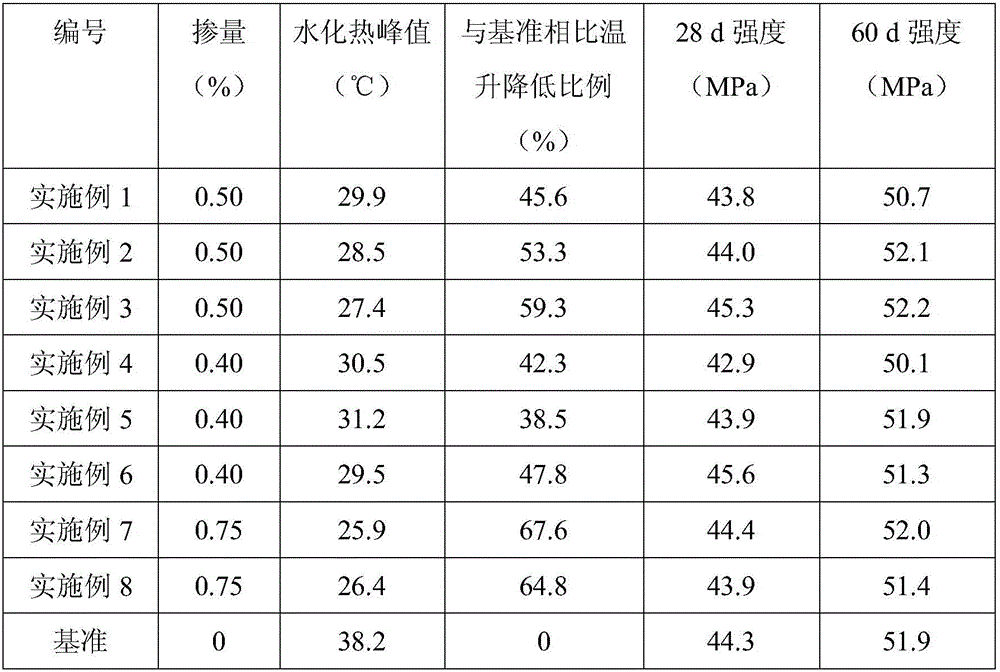

Examples

Embodiment 1

[0028] Disperse 180g of commercially available glucose in 500mL of anhydrous tetrahydrofuran, add 36g of sodium hydride and react for 3h, add dropwise 300g of p-chloromethylstyrene under constant stirring, react at 30°C for 36h, then precipitate in ice ether, and wash Three times, vacuum-dried to obtain the glucose styrene monomer of the present invention;

[0029] Dissolve 100 g of the above glucose styrene monomer in 900 g of a mixture of ethanol / water with a mass ratio of 1:5, add 5 g of stabilizer polyethylene glycol and 7.9 g of initiator azobiscyanovaleric acid, stir evenly, and nitrogen protection Next, react at 75°C for 16h. The reaction is stopped, the product is placed in a centrifuge tube and centrifuged, and the precipitate is washed with water three times, dried in vacuum, crushed and sieved (100 mesh), which is the cement hydration heat regulating material of the present invention.

Embodiment 2

[0031] Change the quality of initiator azobiscyanovaleric acid to 15.8g, and others are consistent with Example 1.

Embodiment 3

[0033] Change the quality of the initiator azobiscyanovaleric acid to 23.7g, and the others are consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com