Concrete sulfur-resistant anti-rust corrosion-resistant compacting agent and preparation method thereof

A concrete and compacting agent technology, applied in the field of concrete admixtures, can solve the problems of ineffective protection of coating life, poor concrete durability, concrete structure damage, etc., achieve excellent resistance to chloride ion penetration, maintain construction performance, reduce Overall cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

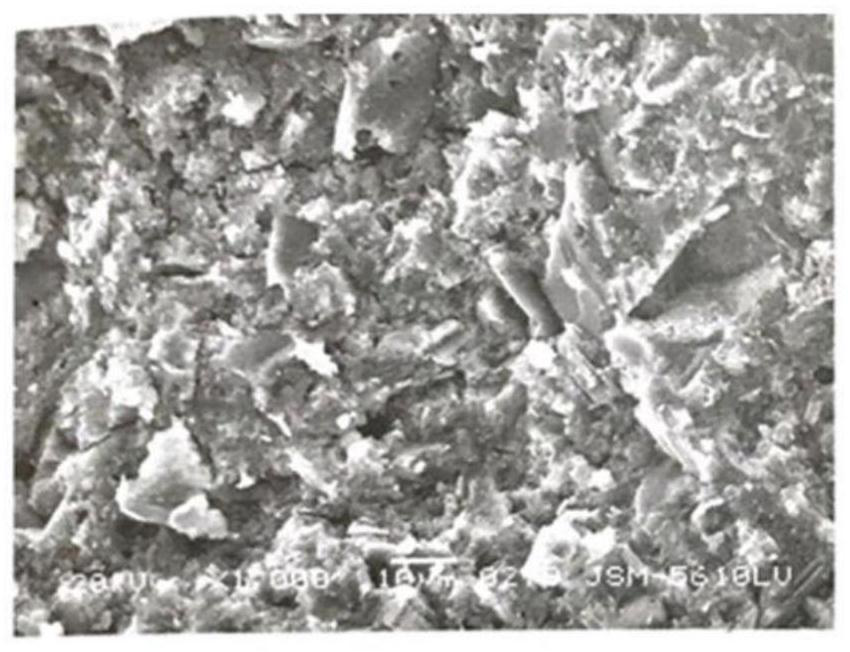

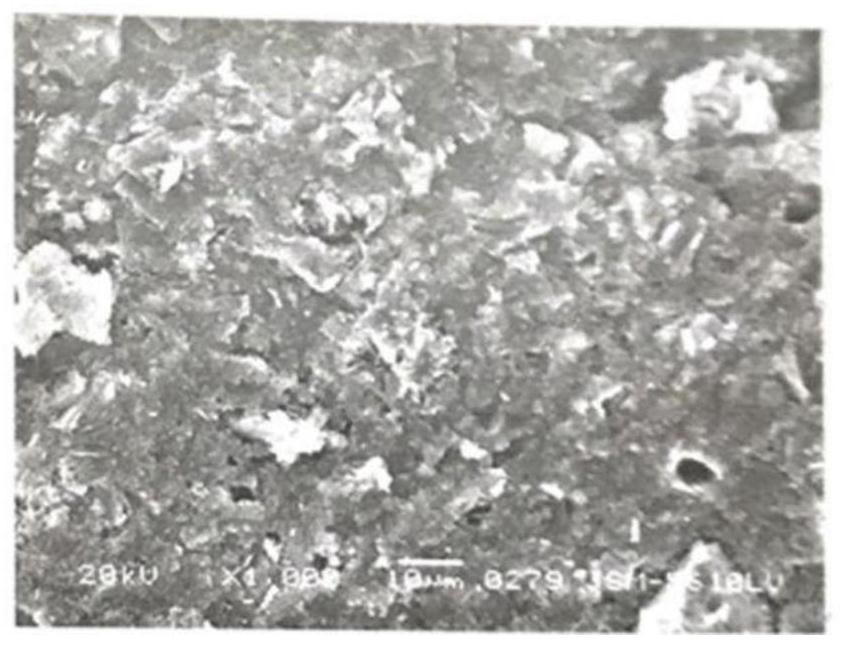

Image

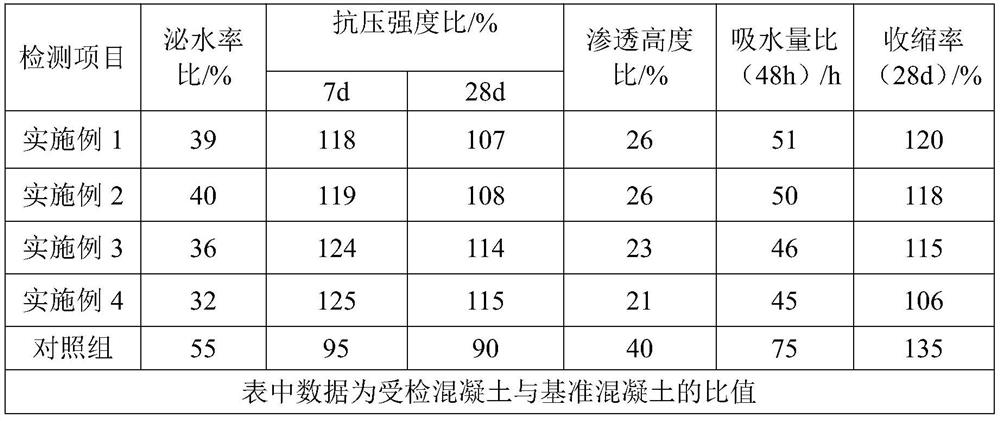

Examples

Embodiment 1

[0053] This embodiment provides a concrete anti-sulfur, anti-rust, anti-corrosion and compacting agent, which is prepared from the following raw materials:

[0054] Calcium sulfoaluminate, 5 parts by weight;

[0055] Basalt fiber, 1 part by weight;

[0056] Quaternary ammonium salt surfactant, 0.1 parts by weight;

[0057] Sodium silicate, 26 parts by weight;

[0058] Sodium nitrite, 0.1 parts by weight;

[0059] oleic acid, 1 part by weight;

[0060] Polyurethane resin, 0.1 parts by weight;

[0061] Water, 40 parts by weight.

[0062] The preparation method of the concrete anti-sulfur, anti-rust, anti-corrosion compacting agent described in this embodiment comprises the following steps:

[0063] (1) Under heating conditions, add calcium sulfoaluminate to water at 60°C, and stir well;

[0064] (2) Add basalt fiber to the solution obtained in step (1), stir for 8 seconds, after cooling down to 40°C, add a quaternary ammonium salt surfactant, and stir for 15 seconds;

[...

Embodiment 2

[0067] This embodiment provides a concrete anti-sulfur, anti-rust, anti-corrosion and compacting agent, which is prepared from the following raw materials:

[0068] Calcium sulfoaluminate, 8 parts by weight;

[0069] Basalt fiber, 0.1 parts by weight;

[0070] Quaternary ammonium salt surfactant, 1 part by weight;

[0071] Sodium silicate, 18 parts by weight;

[0072] Sodium nitrite, 1 part by weight;

[0073] oleic acid, 0.1 parts by weight;

[0074] Polyurethane resin, 1 part by weight;

[0075] Water, 60 parts by weight.

[0076] The preparation method of the concrete anti-sulfur, anti-rust, anti-corrosion compacting agent described in this embodiment comprises the following steps:

[0077] (1) Under heating conditions, add calcium sulfoaluminate to water at 80°C, and stir well;

[0078] (2) Add basalt fiber to the solution obtained in step (1), stir for 20 seconds, after cooling down to 50°C, add a quaternary ammonium salt surfactant, and stir for 25 seconds;

[00...

Embodiment 3

[0081] This embodiment provides a concrete anti-sulfur, anti-rust, anti-corrosion and compacting agent, which is prepared from the following raw materials:

[0082] Calcium sulfoaluminate, 6.5 parts by weight;

[0083] Basalt fiber, 0.55 parts by weight;

[0084] Quaternary ammonium salt surfactant, 0.55 parts by weight;

[0085] Sodium silicate, 22 parts by weight;

[0086] Sodium nitrite, 0.55 parts by weight;

[0087] Tongoleic acid, 0.55 parts by weight;

[0088] Polyurethane resin, 0.55 parts by weight;

[0089] Water, 50 parts by weight;

[0090] And 20% silicone oil by mass of calcium sulfoaluminate.

[0091] The preparation method of the concrete anti-sulfur, anti-rust, anti-corrosion compacting agent described in this embodiment comprises the following steps:

[0092] (1) Under the heating condition of 90°C, fully mix the sulfoaluminate and silicone oil, then add the mixture of calcium sulfoaluminate and silicone oil into the hot water at 90°C, and stir well; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com