A cement hydration heat control material and its preparation method

A cement hydration and thermal control technology, applied in the field of concrete admixtures, can solve the problems of inability to add small molecular sugar units, low esterification efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

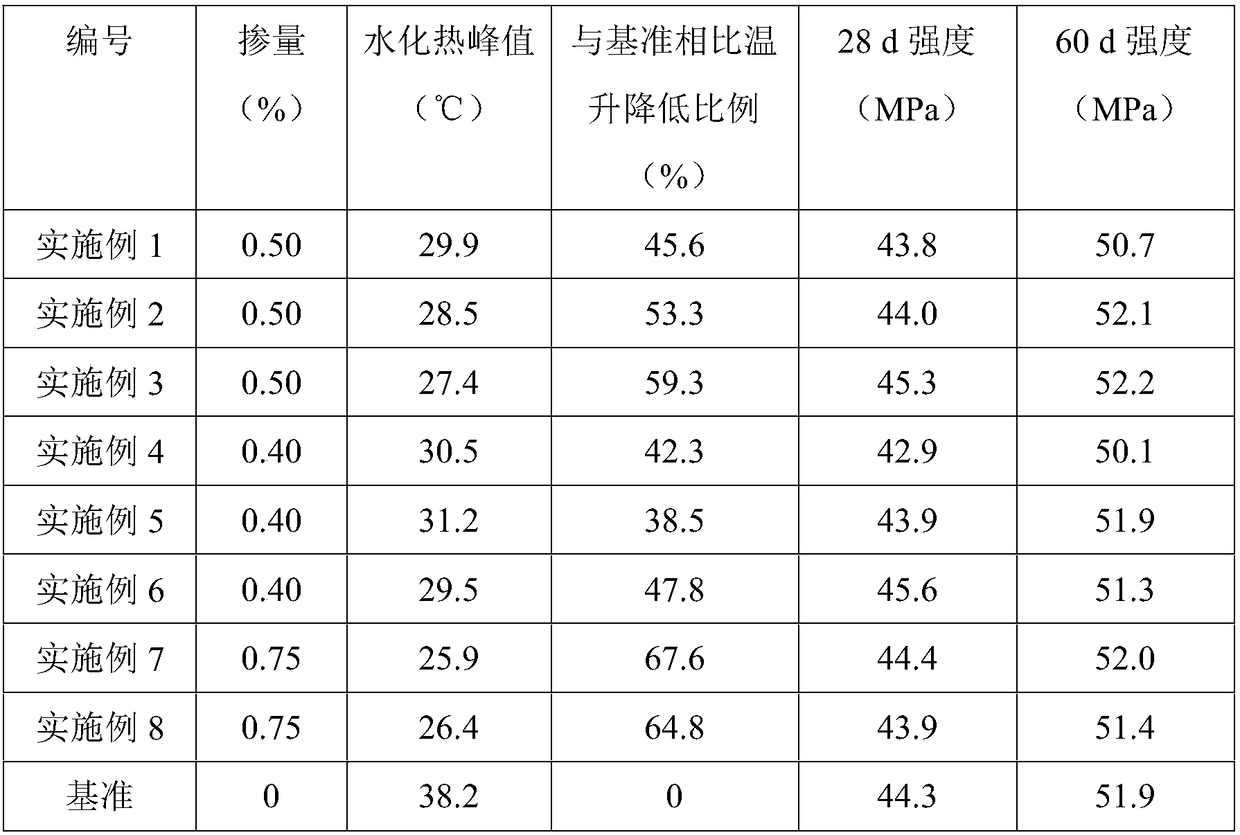

Examples

Embodiment 1

[0028] Disperse 180g of commercially available glucose in 500mL of anhydrous tetrahydrofuran, add 36g of sodium hydride and react for 3h, add 300g of p-chloromethylstyrene dropwise with constant stirring, react at 30°C for 36h, then precipitate in glacial ether and wash three times, vacuum-drying to obtain the glucose styrene monomer of the present invention;

[0029] Dissolve 100g of the above-mentioned glucose styrene monomer in a mixture of 900g ethanol / water with a mass ratio of 1:5, add 5g stabilizer polyethylene glycol and 7.9g initiator azodicyanovaleric acid, stir evenly, and protect with nitrogen. and react at 75 °C for 16 h. The reaction was stopped, the product was placed in a centrifuge tube for centrifugation, washed and precipitated with water three times, vacuum-dried, pulverized and sieved (100 mesh), which is the cement hydration heat regulation material of the present invention.

Embodiment 2

[0031] The mass of the initiator azodicyanovaleric acid was changed to 15.8 g, and the others were the same as those in Example 1.

Embodiment 3

[0033] The mass of the initiator azodicyanovaleric acid was changed to 23.7 g, and the others were the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com