Concrete column pouring construction method based on telescopic string device

A technology of concrete columns and construction methods, which is applied in the direction of construction, building structure, and construction materials, can solve the problems of time-consuming and labor-intensive operations, and low efficiency of concrete pouring, so as to reduce mechanical coordination, avoid concrete segregation, and improve pouring efficiency. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

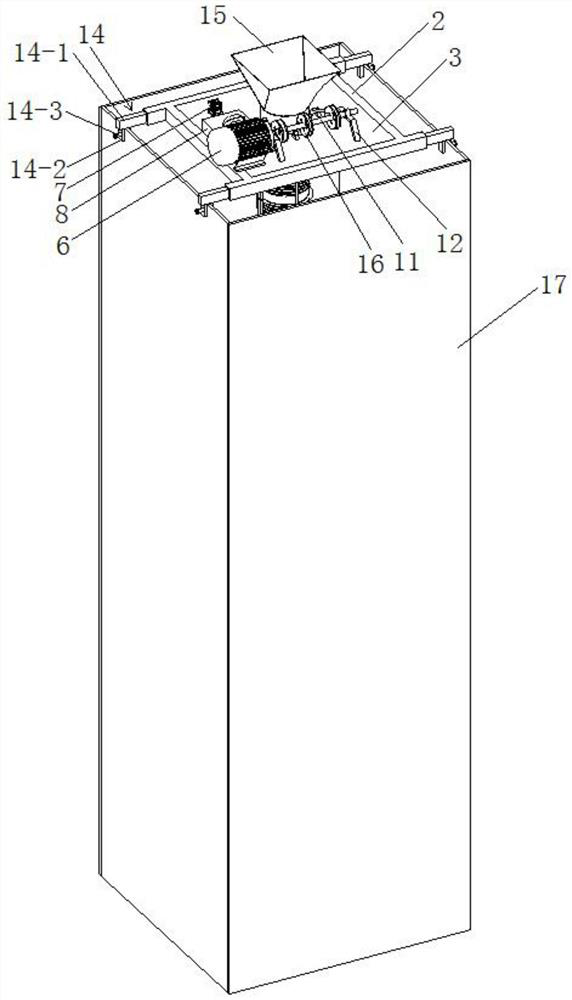

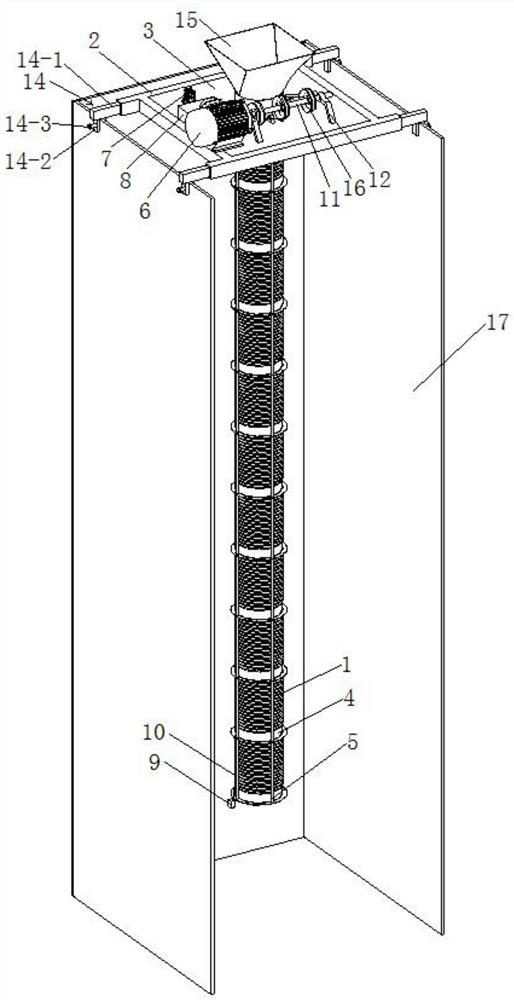

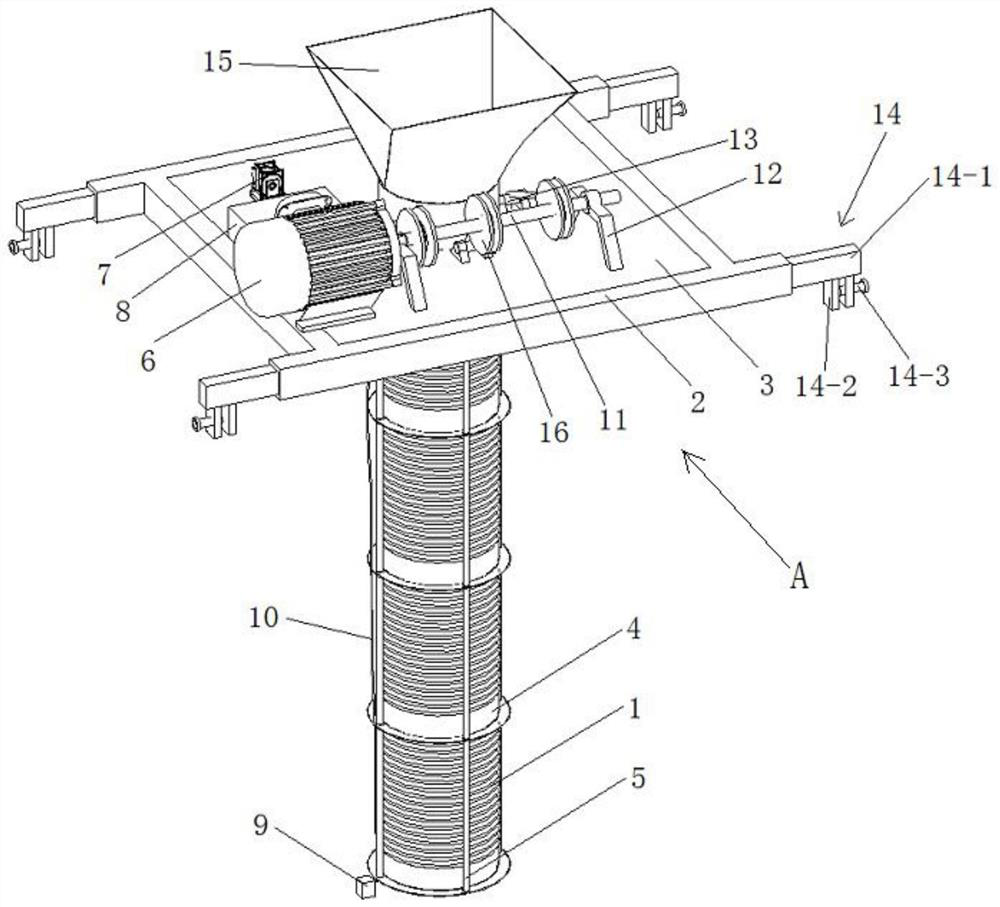

[0059] like Figure 1 to Figure 6 As shown, the telescopic stringer device of the present invention includes a stringer 1, a positioning mechanism disposed at the top of the stringer 1 and used for positioning the stringer 1, and a positioning mechanism disposed on the positioning mechanism and used to control the expansion and contraction of the stringer 1 The control module, the serial tube 1 includes a plurality of single-section telescopic serial tubes connected end to end in sequence, and the plurality of single-section telescopic serial tubes are connected by flanges 4;

[0060] The positioning mechanism includes a support frame 2 , a support plate 3 arranged on the support frame 2 and locking members 14 arranged on the four corners of the support frame 2 . A hopper 15 is installed on the unloading port, and a drive mechanism that drives the string cylinder 1 to expand and contract is provided on the support plate 3. The drive mechanism includes a motor 6 and a transmiss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com