Clay tunnel steel lining concrete pouring anti-floating structure and construction method

A technology of concrete and concrete layers, which is applied in earthwork drilling, tunnel lining, tunnels, etc., can solve problems affecting the construction quality of steel lining, damage to anti-corrosion coating and steel lining base material, and complicated procedures, so as to improve construction quality, The effect of avoiding secondary painting and speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

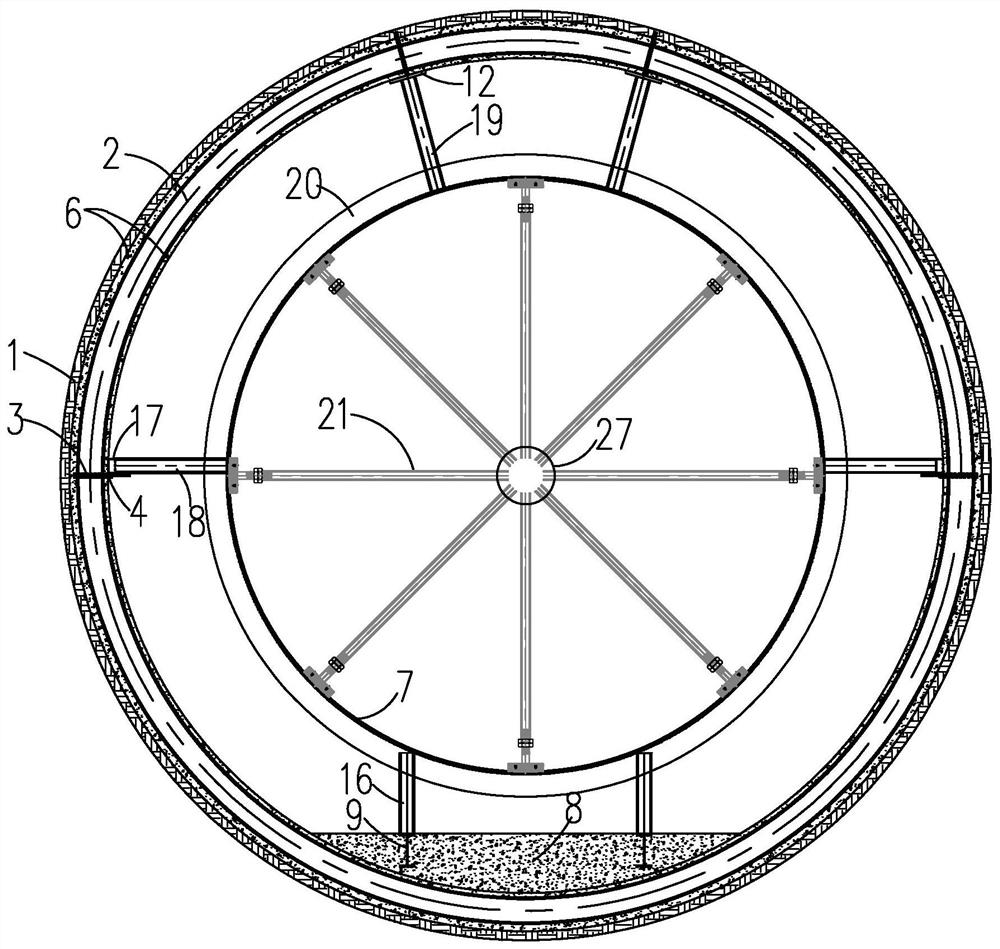

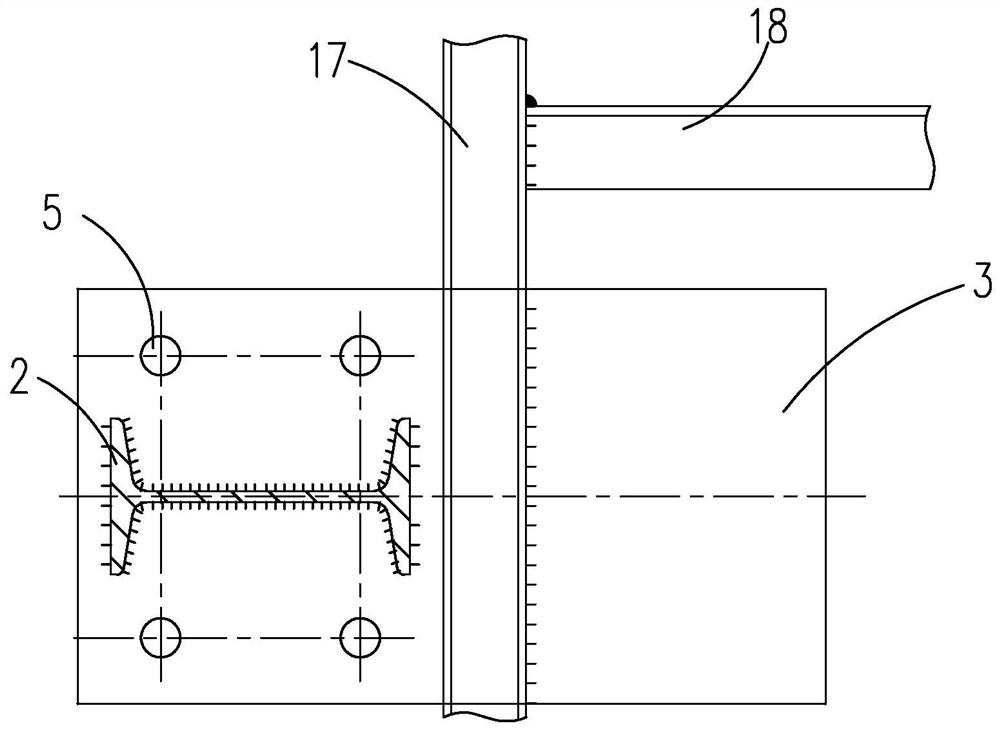

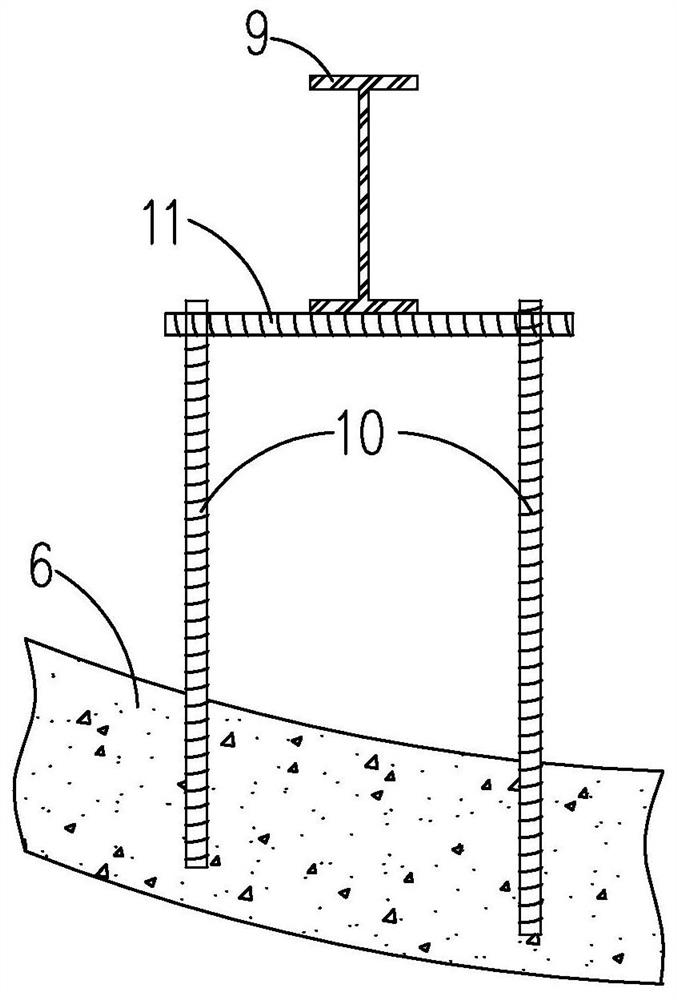

[0033] Such as Figure 1-Figure 6 As shown, the present invention provides a clay tunnel steel-lined concrete pouring anti-floating structure, the steel lining 7 is arranged inside the clay tunnel 1, two semi-circular steel arch supports 2 are arranged on the inner wall of the tunnel, and pass through the waist of the tunnel. The spliced plate structure is connected, the steel arch support 2 is set in the concrete layer 6 on the inner wall of the tunnel, the concrete floor 8 is set at the bottom of the tunnel, the I-beam 9 is set inside the concrete floor 8, and the top arch of the tunnel concrete layer 6 is set with nails. Plate 12, the spliced plate structure, the I-beam 9 and the nail plate 12 are all welded and fixed with the stiffening ring 20 of the steel lining 7, and the inside of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com