Crystallizer system for continuously casting double-flow plate blanks

A crystallizer and slab technology, applied in the field of crystallizer systems, can solve the problems of large construction investment, high production cost, waste of energy, etc., and achieve the effect of low construction investment, low production cost and resource saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention belongs to the field of metallurgy, and is particularly suitable for a crystallizer device of a one-machine two-strand slab continuous casting machine.

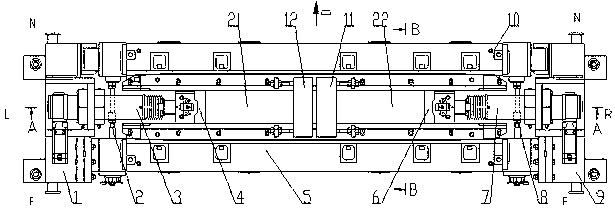

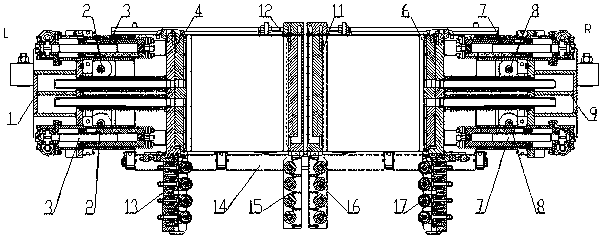

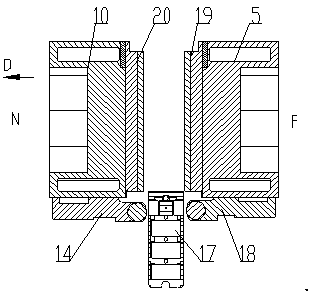

[0025] see Figure 1 to Figure 3 , the specific structure of a crystallizer system for continuous casting of two-stream slabs that the present invention relates to is:

[0026] Including frame assembly, wide copper plate assembly, narrow copper plate assembly, intermediate plate assembly, width adjustment device, clamping device and foot roller assembly;

[0027] The frame assembly includes a left side frame 1, a right side frame 9, an inner arc frame 10 and an outer arc frame 5, wherein the left side frame 1 is connected with the left side of the inner arc frame 10 and the outer arc frame 5 respectively; the right side frame 9 Connect with the right side of inner arc frame 10 and outer arc frame 5 respectively;

[0028] The wide-faced copper plate assembly includes an inner arc copper plate assembly 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com