Crystallizer device for continuously casting hollow tube blanks

A technology of crystallizer and hollow tube is applied in the field of crystallizer device for continuous casting of hollow tube blanks, which can solve the problems of wasting energy, large waste of resources and high production cost, and achieve the effects of reducing production cost, saving resources and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structure and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

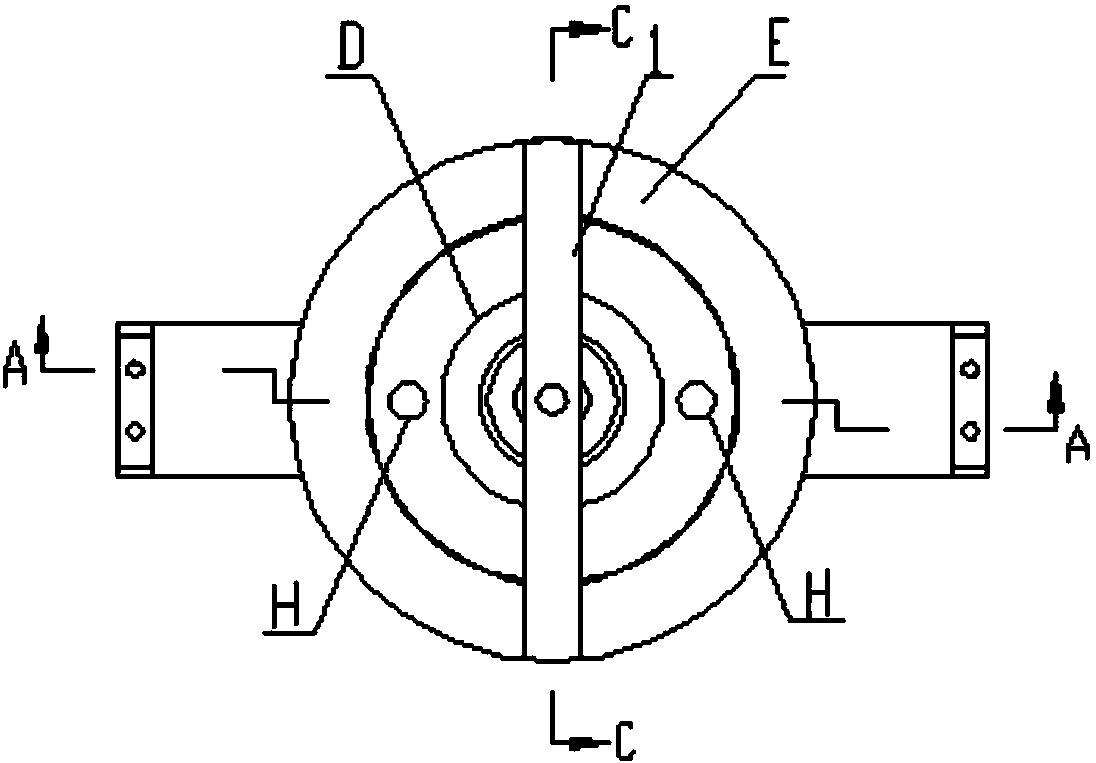

[0015] refer to figure 1 , a mold device for continuous casting of hollow tube billets, the device consists of three parts: the inner ring copper tube assembly D, the outer ring copper tube assembly E and the connecting beam 1 between the inner ring and the outer ring, through which the inner ring The ring copper tube assembly and the outer ring copper tube assembly are connected as a whole.

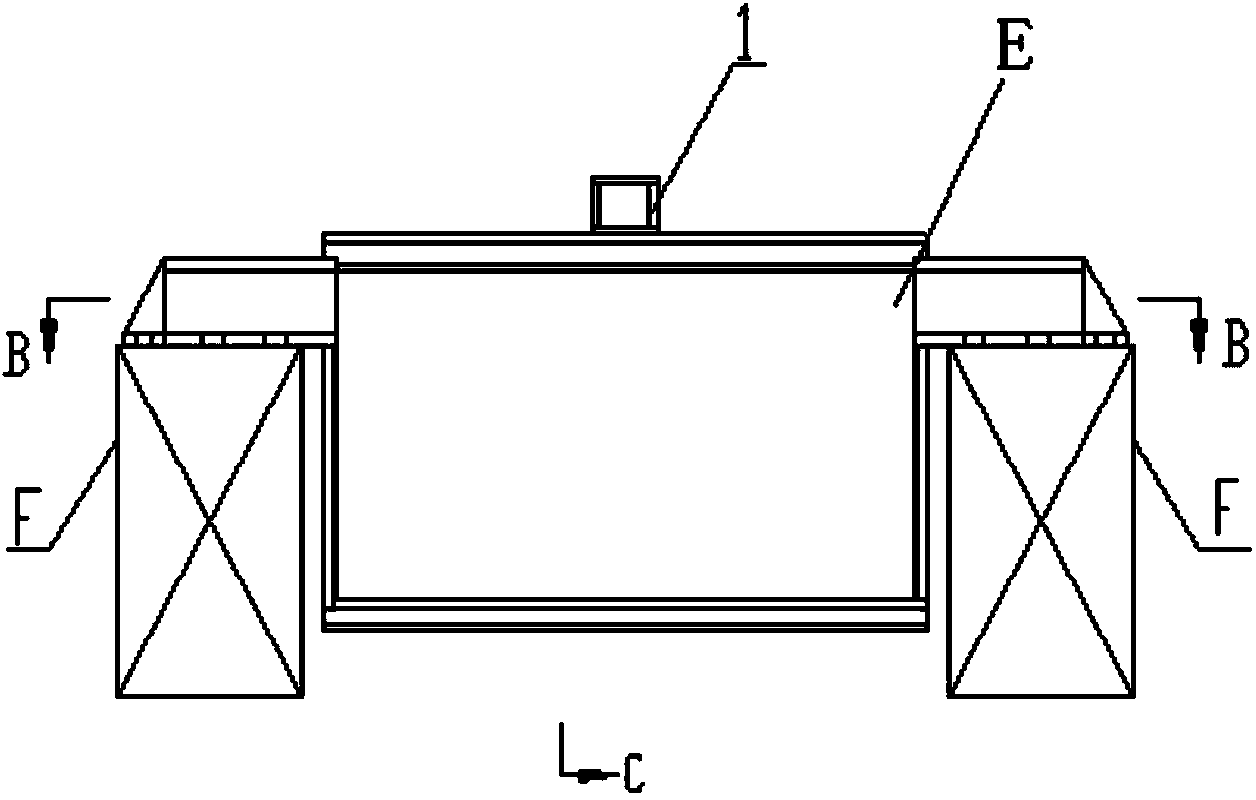

[0016] refer to figure 2 , the device is connected with the vibration device F by bolts and driven by a vibration cylinder to realize sinusoidal or non-sinusoidal vibration.

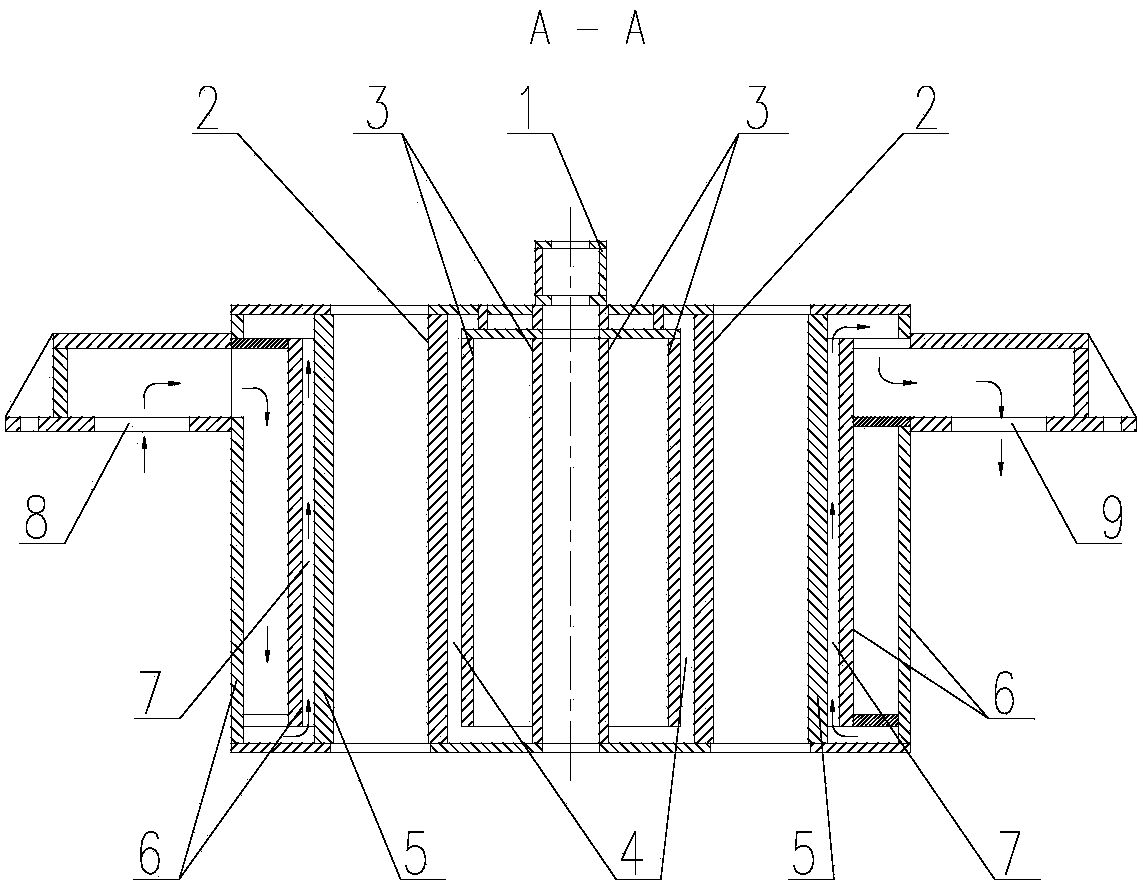

[0017] refer to image 3 , the inner ring copper tube assembly D includes the inner ring copper tube 2, the inner ring copper tube 2 and the inner ring frame 3 are assembled to form a water gap 4 between the two, and the cooling water of the inner ring copper tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com