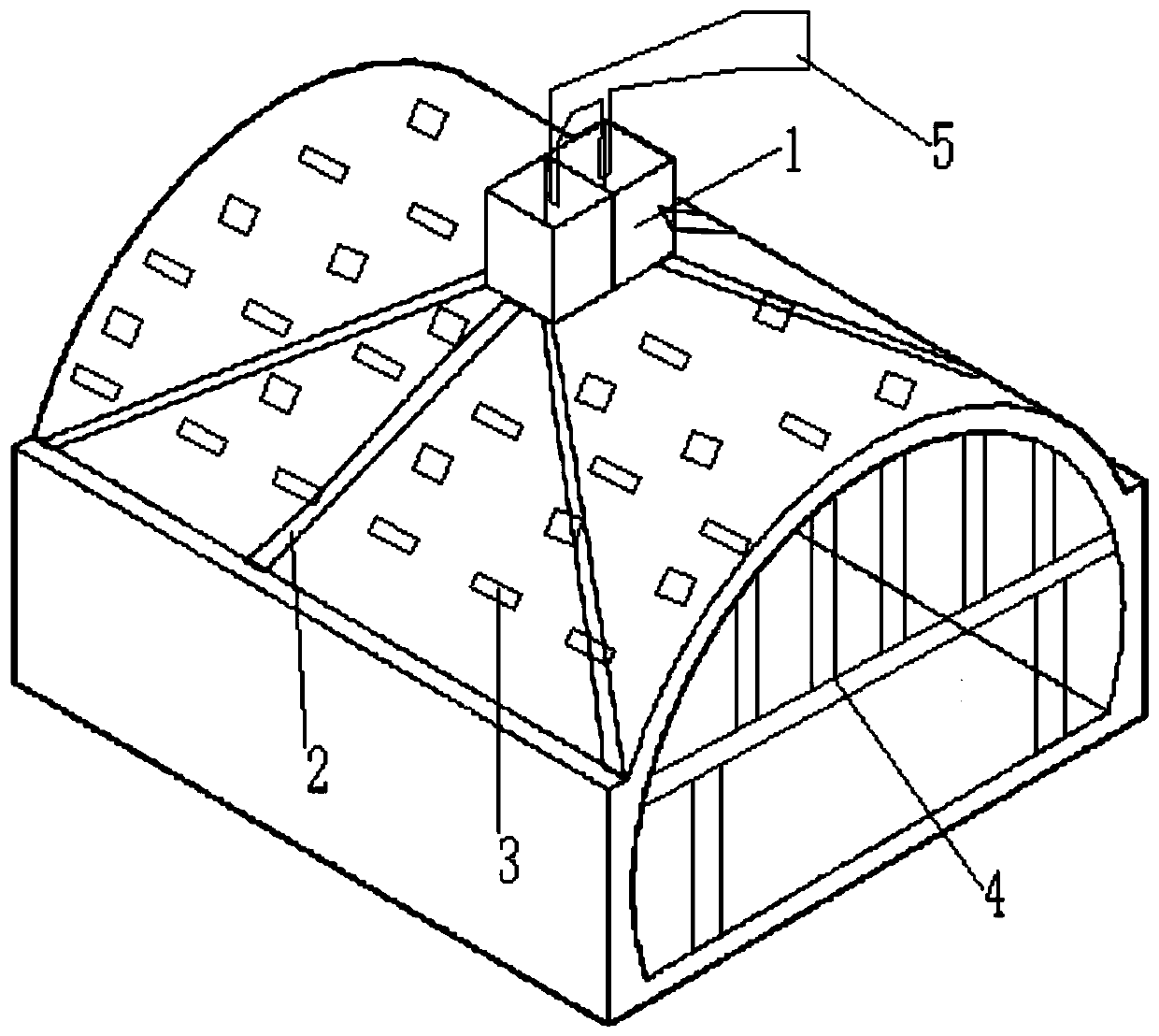

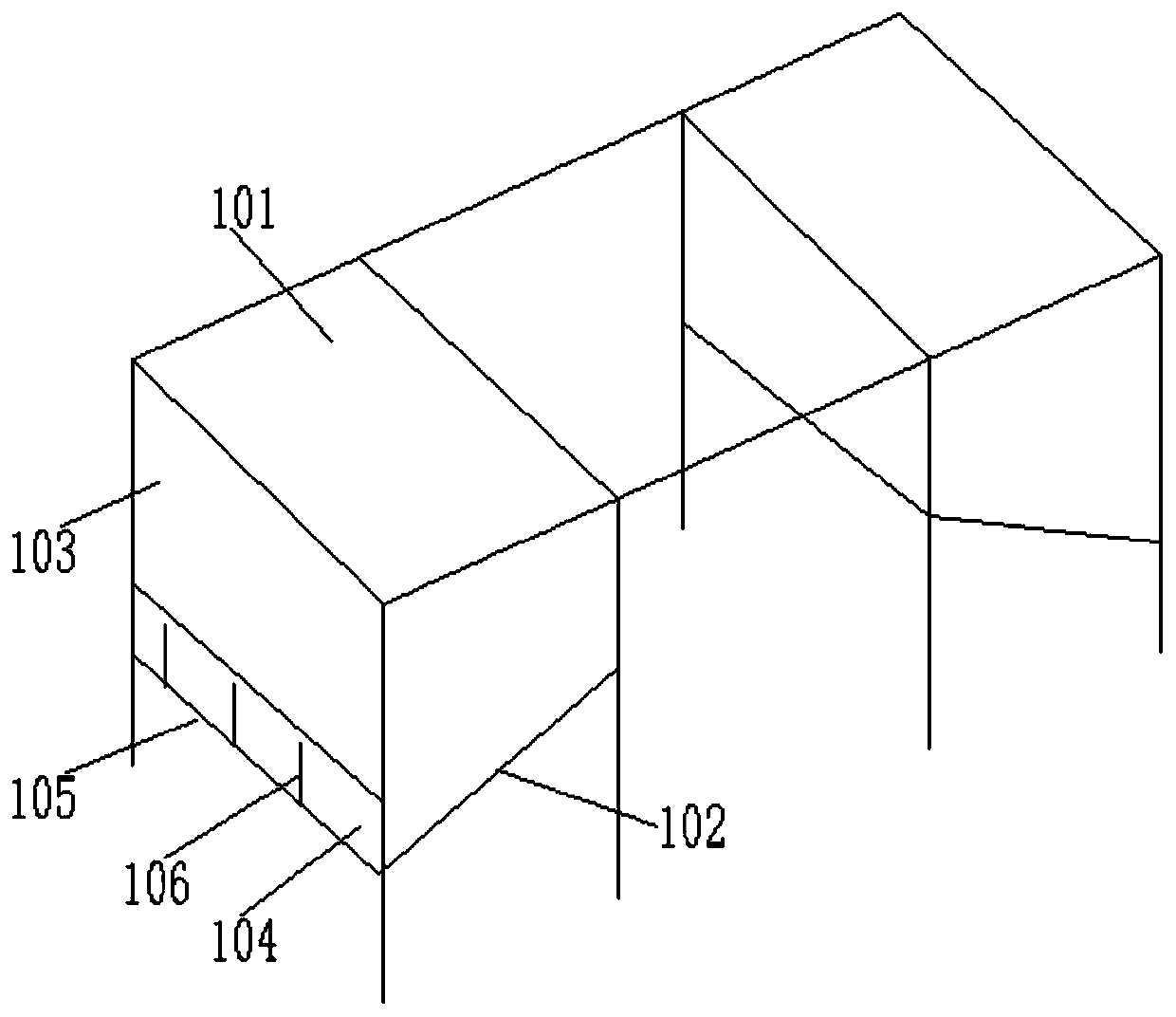

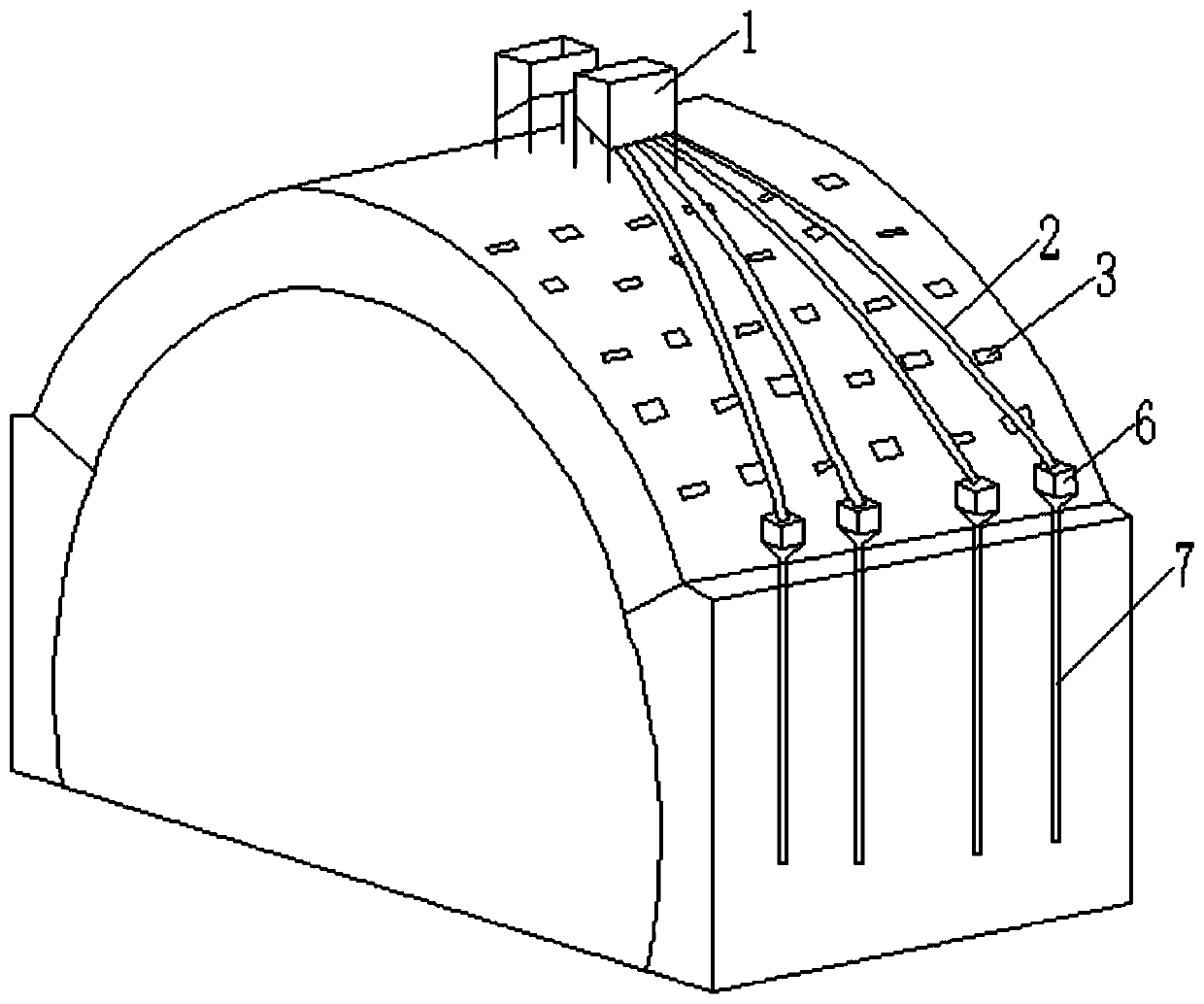

Symmetrical synchronous layered distributing and casting system and construction method for open trench tunnel lining

A technology of layered material distribution and open-cut tunnels, which is applied in construction, artificial islands, water conservancy projects, etc., can solve problems such as substandard concrete pouring quality, and avoid excessive deviation of lining dimensions, reduce labor intensity, and reduce slump small loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0091] This construction method has been applied in the construction of the No. 2 open-cut tunnel of Beijing-Xiong Intercity Railway Airport, which effectively avoids the quality defects of conventional tunnel lining concrete construction and improves the construction quality of the lining. Compared with the traditional concrete process, each lining can save about 2 hours of time and 2 workers.

[0092] Jingxiong Intercity Railway Airport No. 2 Tunnel connects to the underground station of Beijing New Airport in the north, and passes through the Yongding Henan Embankment in the south to expose the ground. Among them, the section DK46+092~DK48+000 within the scope of this bidding section is the unadjusted part of the line, with a length of 1908m, and the section DK48+000~DK53+300 is the adjusted part of the line, with a total length of 7208m.

[0093] The area to which the line belongs is located at the northern edge of the North China Plain, bounded by Huangcun. The north is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com