Agricultural integral continuous extrusion forming machine for elliptic concrete pipe

A concrete and elliptical technology, which is applied in the field of continuous extrusion molding machines for concrete pipes, can solve the problems of poor joint joints, low pipe efficiency, high cost, etc., to solve the bottom suspension and insufficient material supply, reduce production costs, The effect of high pouring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

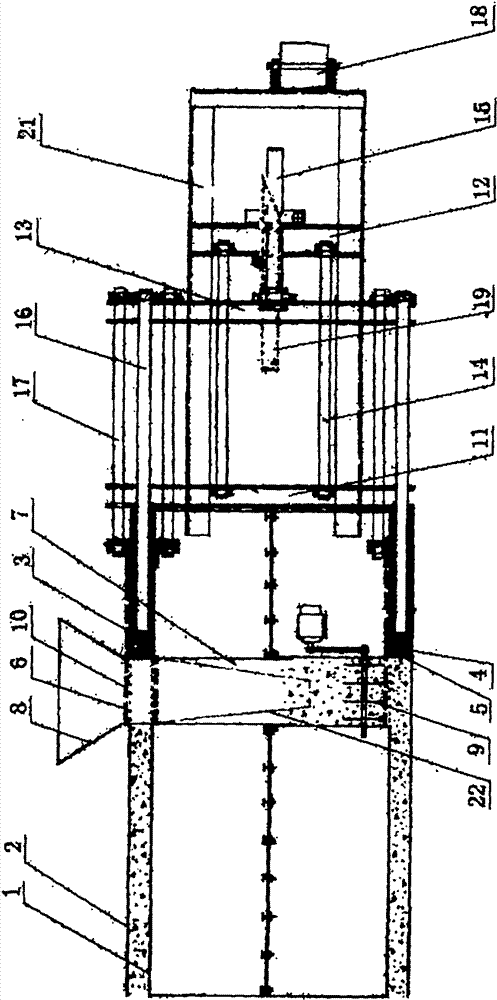

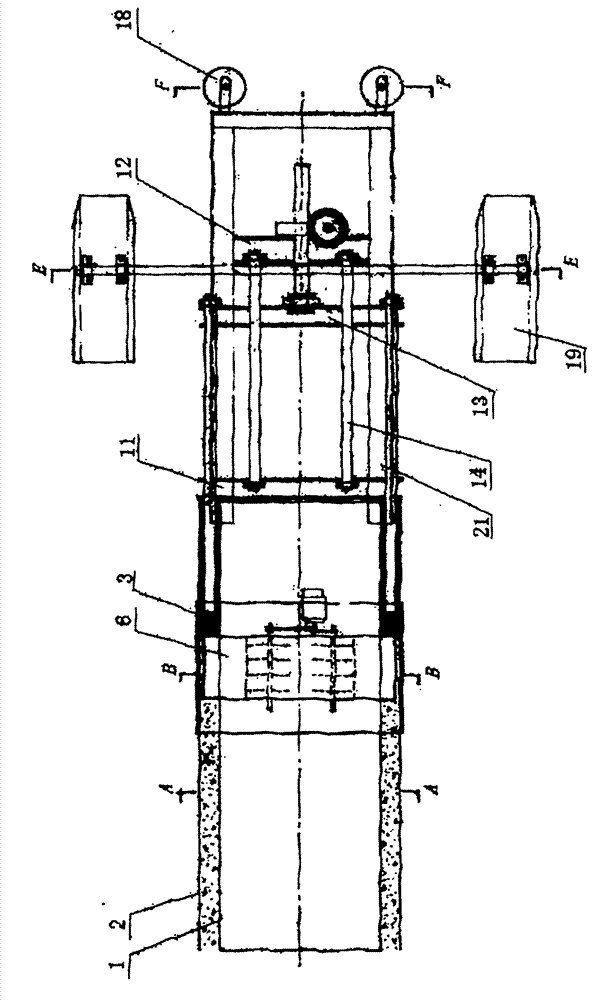

[0025] Such as figure 1 , 2 As shown, it includes a frame 21, an inner mold 1, an outer mold 2, a compression piston 3, an oval ring plate 5, a rubber pad 4, a feed port 6, a feed channel 7, a feed hopper 8, a crawler 9, a slide Ram 10, differential inner push plate 20, front end plate 11, rear end plate 12, push plate 13, guide rod 14, gate push rod 16, piston push rod 17, screw rod 15, guide roller 18 and slide plate 19.

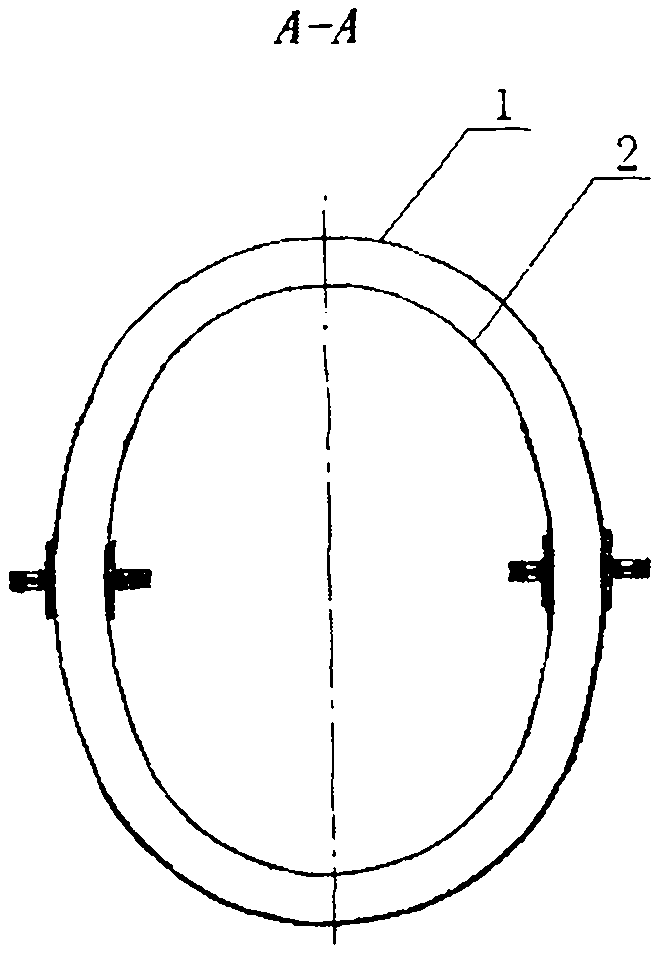

[0026] The front end of the frame 21 is equipped with a pipeline compression molding mechanism, which includes an inner mold 1, an outer mold 2, and a compression piston 3. Both the inner mold 1 and the outer mold 2 are bent into arcs by two steel plates and then connected and fixed into an ellipse. (see image 3 ), the inside and outside of the inner and outer molds are arranged together to form an elliptical ring cavity. The end of the mold cavity is a discharge port, and an elliptical annular compression piston 3 is arranged in the cavity to squeeze ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com