One-step forming and construction equipment and construction method for gutter

A technology of construction equipment and construction method, which is applied in the one-time forming construction equipment and construction field of drainage ditch, to achieve the effect of ensuring the quality of excavation, ensuring the integrity and simplifying the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

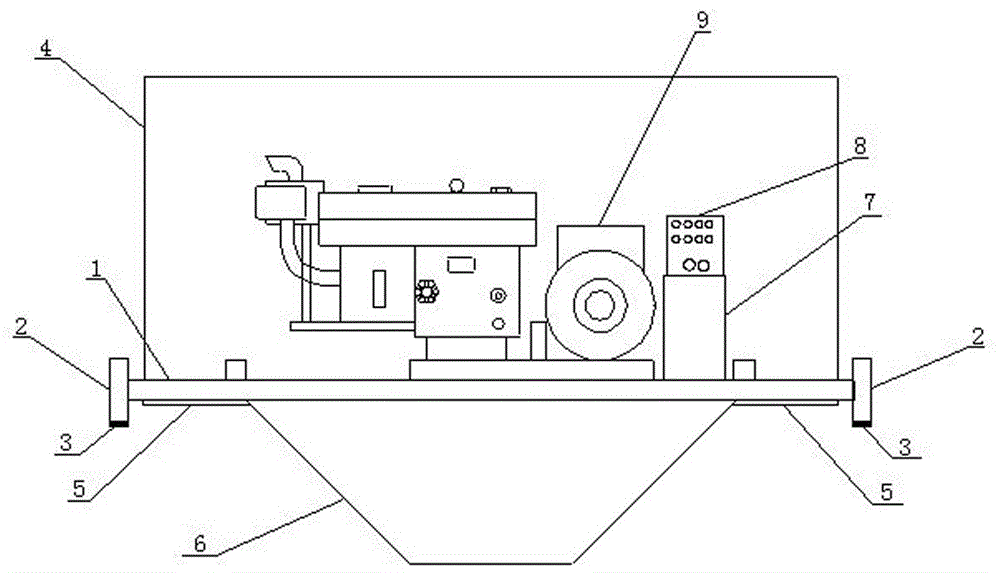

[0022] A drainage ditch one-time molding construction equipment, including running rails 3 placed side by side on the top of the slope on both sides of the drainage ditch, rollers 2 rolling and matching with the running rails 3, and a limiting platform supported between all the rollers 2, fixed on Generator 8 above the limiting platform, vibrating table 7 and feed bin 4, console 8 for controlling the vibrating table 7, shaped steel mold 6 fixed below the limiting platform and matched with the drainage ditch,

[0023] The console 8 controls the rotation of the roller 2 through a propeller, and the output end of the vibrating table 7 is connected with the shaped steel mold 6, and there is a spacer connected with the feed bin 4 under the limiting platforms on both sides of the shaped steel mold 6. The discharge port 5 is fixed with a standard rod 1 on the limiting platform above the drainage ditch.

[0024] During specific implementation, the shape of the shaped steel mold 6 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com