Polycarboxylate superplasticizer with super high early strength and preparation method of polycarboxylate superplasticizer

A technology of early-strength polycarboxylic acid and strong polycarboxylic acid, which is applied in the field of polycarboxylate water reducing agent and its preparation, can solve the problems of difficulty in meeting the requirements of high-rise buildings, prolonging the setting time of concrete, affecting the performance of products, and improving the performance of the product. The effect of anti-corrosion function, shortened production cycle, and high early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

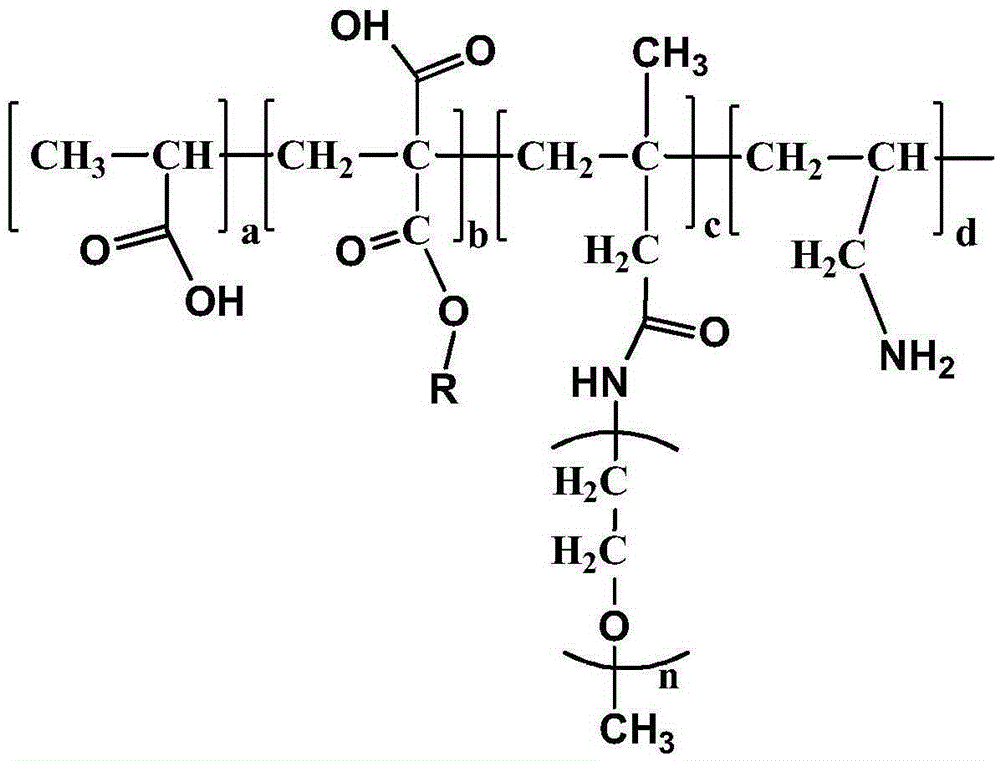

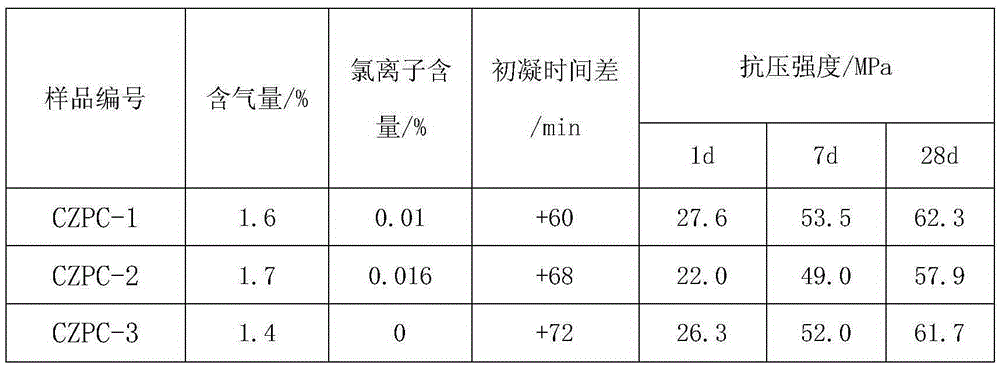

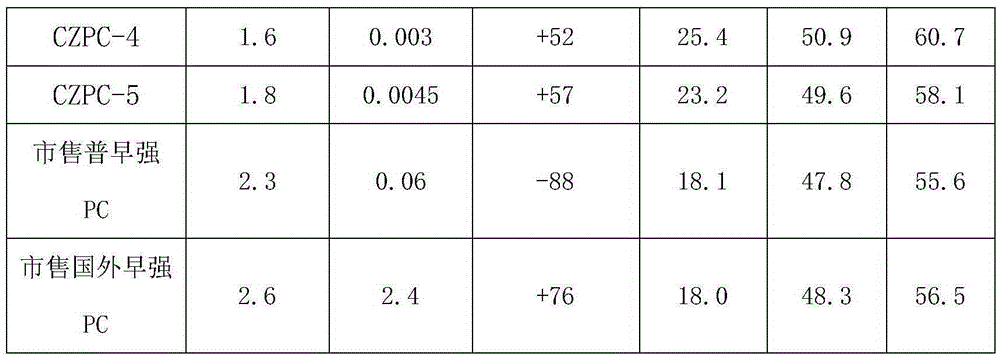

[0023] Embodiment 1: Preparation of super early strength polycarboxylate water reducer

[0024] In a three-neck flask equipped with a thermometer and agitator, add 140g of deionized water and 100g of polyetheramine macromonomer M, stir and heat up to dissolve, add 0.5g of ammonium persulfate at 50°C, then add 20g of monomeric acrylic acid, 5g Allylamine, 5g cisylbutene hydroxyethyl ester and 10g deionized water were mixed and stirred to form a uniform monomer aqueous solution, which was added dropwise into the flask through a peristaltic pump at a constant speed. After the completion, continue to keep the constant temperature for 3 hours, then lower the temperature to 30°C, add sodium hydroxide to neutralize to pH = 7.5, and obtain the super early strength polycarboxylate superplasticizer CZPC-1.

Embodiment 2

[0025] Embodiment 2: Preparation of super early strength polycarboxylate superplasticizer

[0026] In a three-necked flask equipped with a thermometer and a stirrer, add 130g of deionized water and 100g of polyetheramine macromonomer M, stir and heat up to dissolve, add 0.4g of potassium persulfate at 55°C, then add 30g of monomeric acrylic acid, 5g Allylamine, 6g of cisylbutene hydroxyethyl ester and 10g of deionized water were mixed and stirred to form a uniform monomer aqueous solution, which was added dropwise into the flask through a peristaltic pump at a constant speed. After the completion, continue to keep the constant temperature for 4 hours, then lower the temperature to 30°C, add sodium hydroxide to neutralize to pH = 7.5, and obtain the super early strength polycarboxylate superplasticizer CZPC-2.

Embodiment 3

[0027] Embodiment 3: Preparation of super early strength polycarboxylate water reducer

[0028] In a three-necked flask equipped with a thermometer and a stirrer, add 150g of deionized water and 100g of polyetheramine macromonomer M, stir and heat up to dissolve, add 0.5g of ammonium persulfate at 50°C, and then add 25g of monomeric acrylic acid, 4g Allylamine, 8g of cisylbutene hydroxyethyl ester and 10g of deionized water were mixed and stirred to form a uniform monomer aqueous solution, which was added dropwise into the flask through a peristaltic pump at a constant speed. After completion, continue to keep constant temperature for 3 hours, then lower the temperature to 30°C, add sodium hydroxide to neutralize to pH = 7.5, and obtain super early strength polycarboxylate superplasticizer CZPC-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com