Methyl chlorosilane parallel double-effect distillation method

A technology of methylchlorosilane and dimethyldichlorosilane, which is applied in the field of parallel double-effect distillation of methylchlorosilane to achieve reliable process, increase energy consumption and avoid amplification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

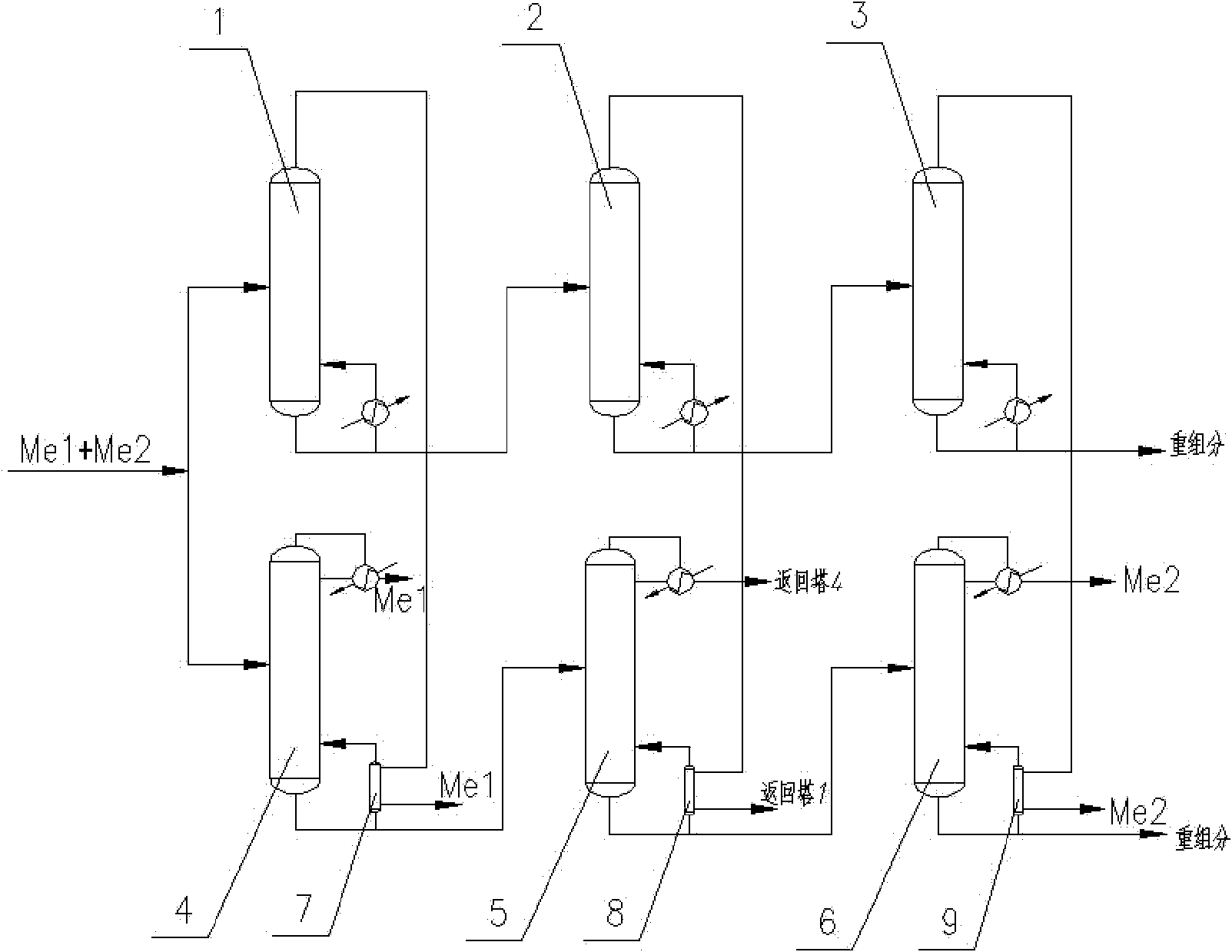

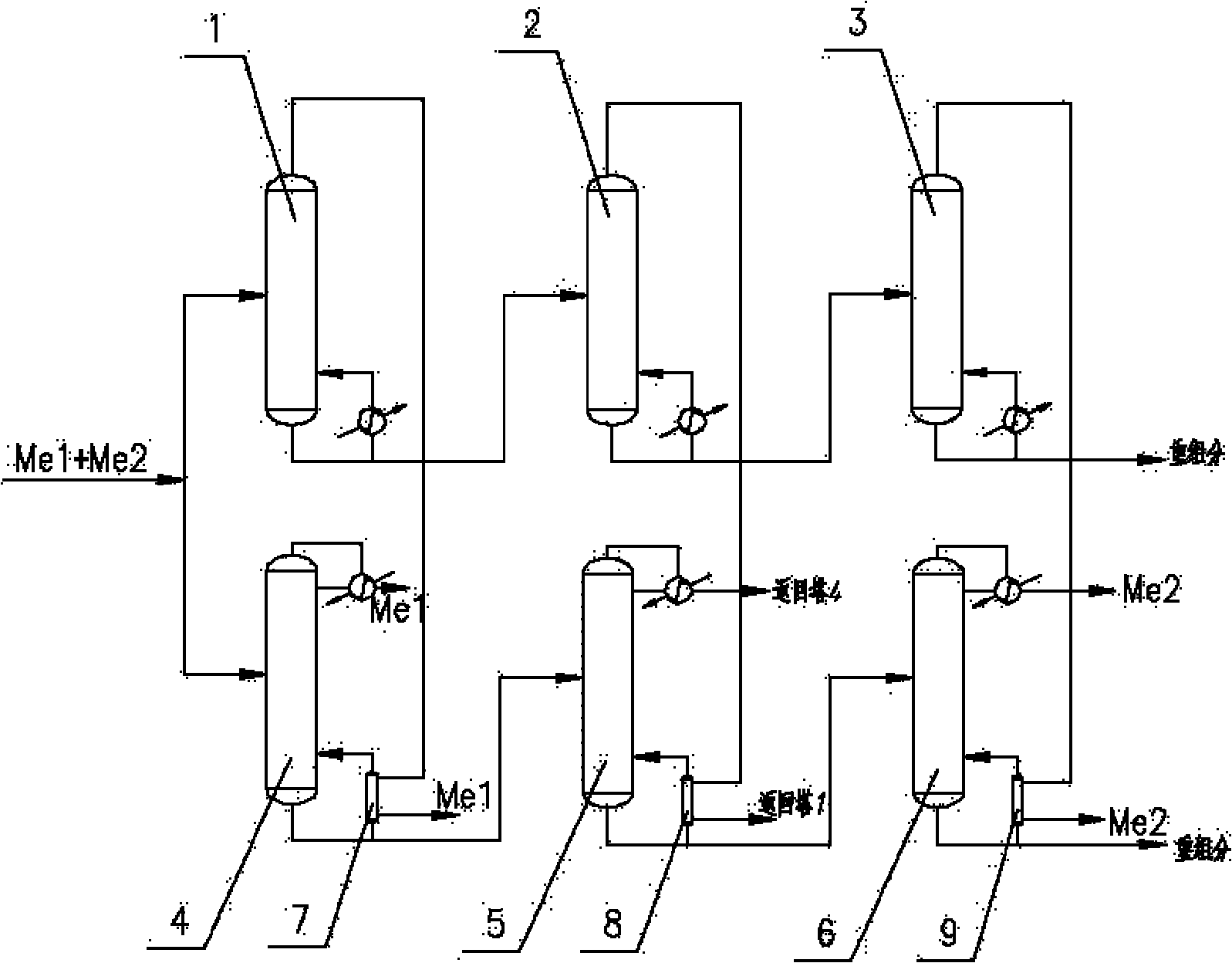

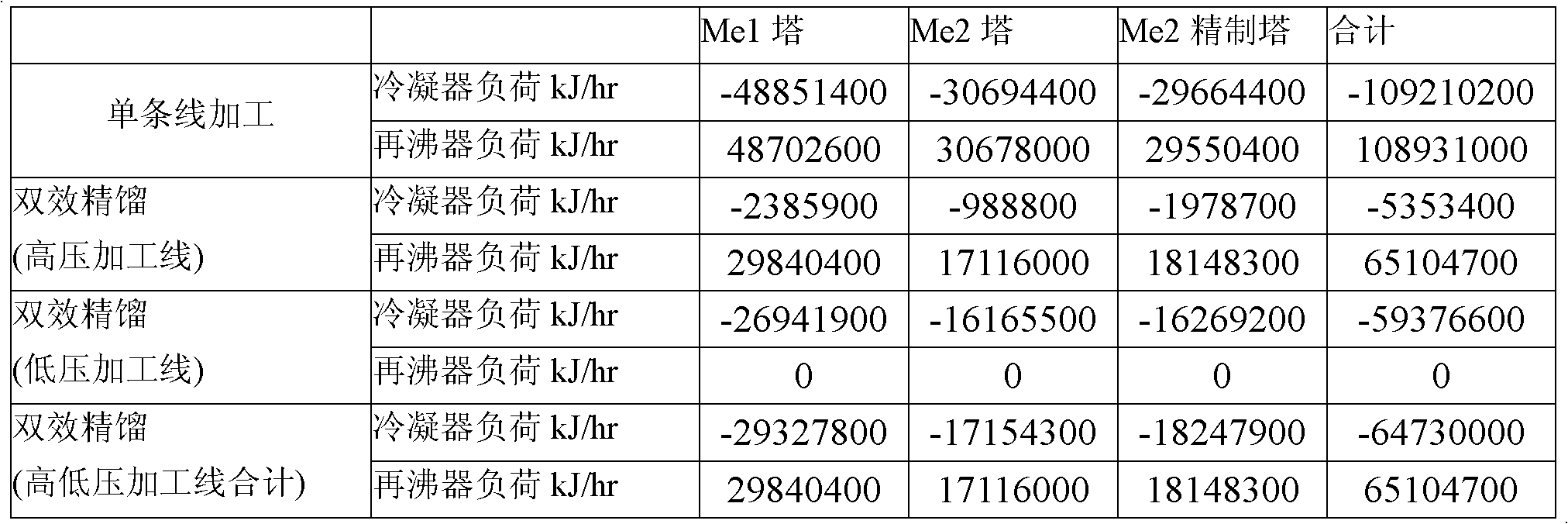

[0026] As shown in Figure 1, it is composed of two processing lines. The separation of Me2 and Me1 adopts the parallel double-effect rectification process of two-column process. The total feed rate is 18750kg / hr, which is equivalent to the output of Me1 and Me2 of 150kt / a. The content of Me2 in the feed is 80%, and the content of Me1 is 10.77% (mass content). The feed rate of the high-pressure processing line is 7963kg / hr, and the feed rate of the low-pressure processing line is 9732kg / hr. One of the materials enters the high-pressure refining and rectification system consisting of the monomethyltrichlorosilane high-pressure tower 1, the dichlorosilane high-pressure tower 2 and the dimethyldichlorosilane high-pressure refining tower 3, and the other one The low-pressure refining and rectifying system composed of trichlorosilane low-pressure tower 4, methyldichlorosilane low-pressure tower 5, and dimethyldichlorosilane low-pressure refining tower 6, said one methyl trichlorosila...

Embodiment 2

[0033] As shown in Figure 1, it is composed of two processing lines. The separation of Me2 and Me1 adopts the parallel double-effect rectification process of the binary tower process. The total feed rate is 18750kg / hr, which is equivalent to the output of Me1 and Me2 of 150kt / a. The content of Me2 in the feed is 80%, and the content of Me1 is 10.77% (mass content). The feed rate of the high-pressure processing line is 7963kg / hr, and the feed rate of the low-pressure processing line is 9732kg / hr. One of the materials enters the high-pressure refining distillation system composed of the binary high-pressure tower and the dimethyldichlorosilane high-pressure refining tower 3, and the other stream enters the binary low-pressure tower and the dimethyldichlorosilane low-pressure refining tower 6 A low-pressure refining and rectifying system composed of the two-element high-pressure tower and the top gas phase of the dimethyldichlorosilane high-pressure refining tower 3 as the bottom ...

Embodiment 3

[0040] As shown in Figure 1, it is composed of two processing lines. The separation of Me2 and Me1 adopts the parallel double-effect rectification process of two-column process. The total feed rate is 18750kg / hr, which is equivalent to the output of Me1 and Me2 of 150kt / a. The content of Me2 in the feed is 80%, and the content of Me1 is 10.77% (mass content). The feed rate of the high-pressure processing line is 7000kg / hr, and the feed rate of the low-pressure processing line is 11750kg / hr. One of the materials enters the high-pressure refining and rectification system composed of a methyltrichlorosilane high-pressure tower 1 and a dichlorosilane high-pressure tower 2, and the other material enters a methyltrichlorosilane low-pressure tower 4, methyldichlorosilane The low-pressure refining and rectifying system composed of silane low-pressure tower 5, the top gas phase of the said monomethyltrichlorosilane high-pressure tower 1, methyldichlorosilane high-pressure tower 2 is res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com