Dimethyl dichlorosilane hydrolysis method for directly producing gaseous hydrogen chloride

A dimethyldichlorosilane, hydrogen chloride technology, applied in chlorine/hydrogen chloride, chemical instruments and methods, organic chemistry and other directions, can solve the problems of low hydrogen chloride gas pressure, large occupation, pipeline blockage, etc., to improve product yield , Reasonable design, not easy to block the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

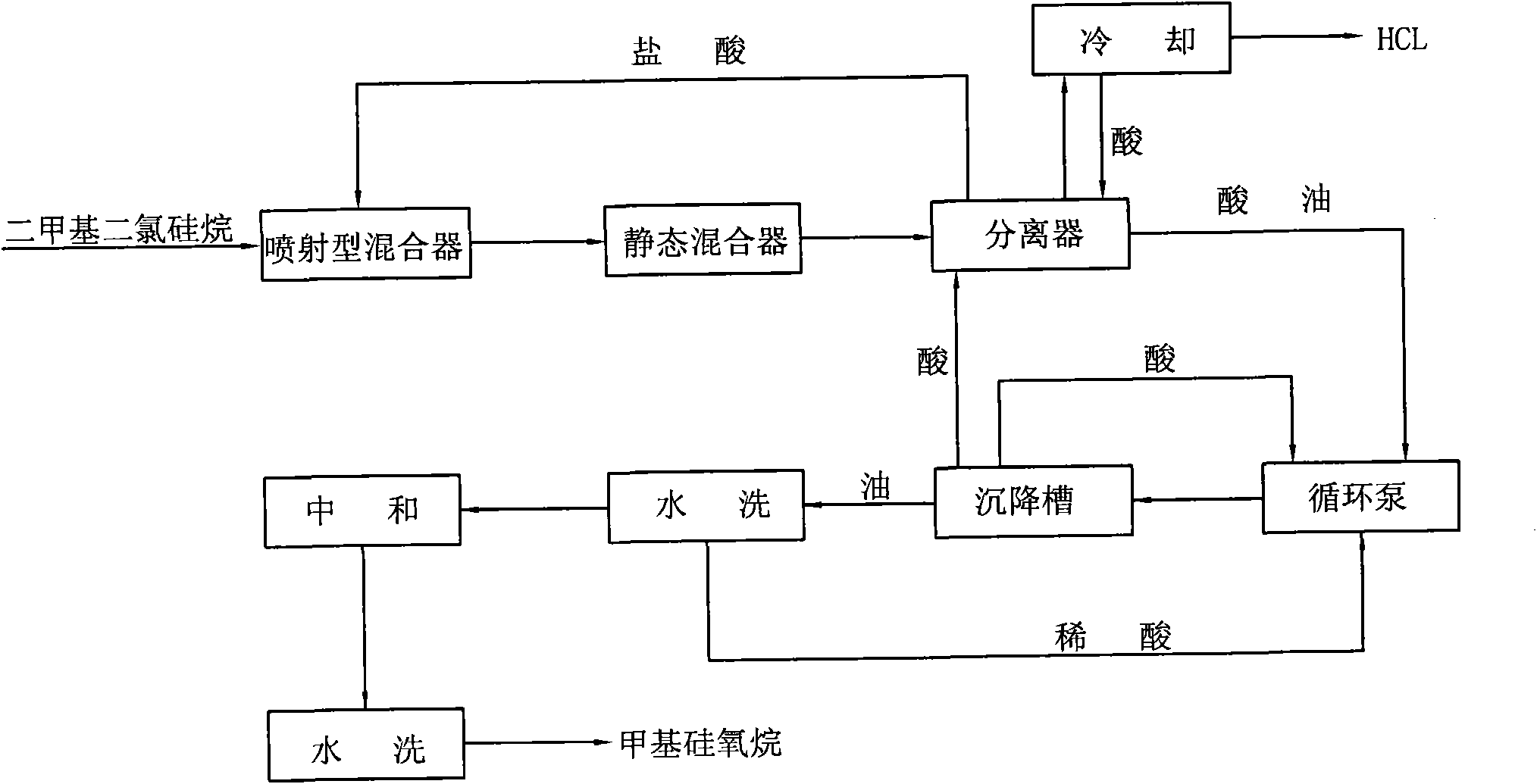

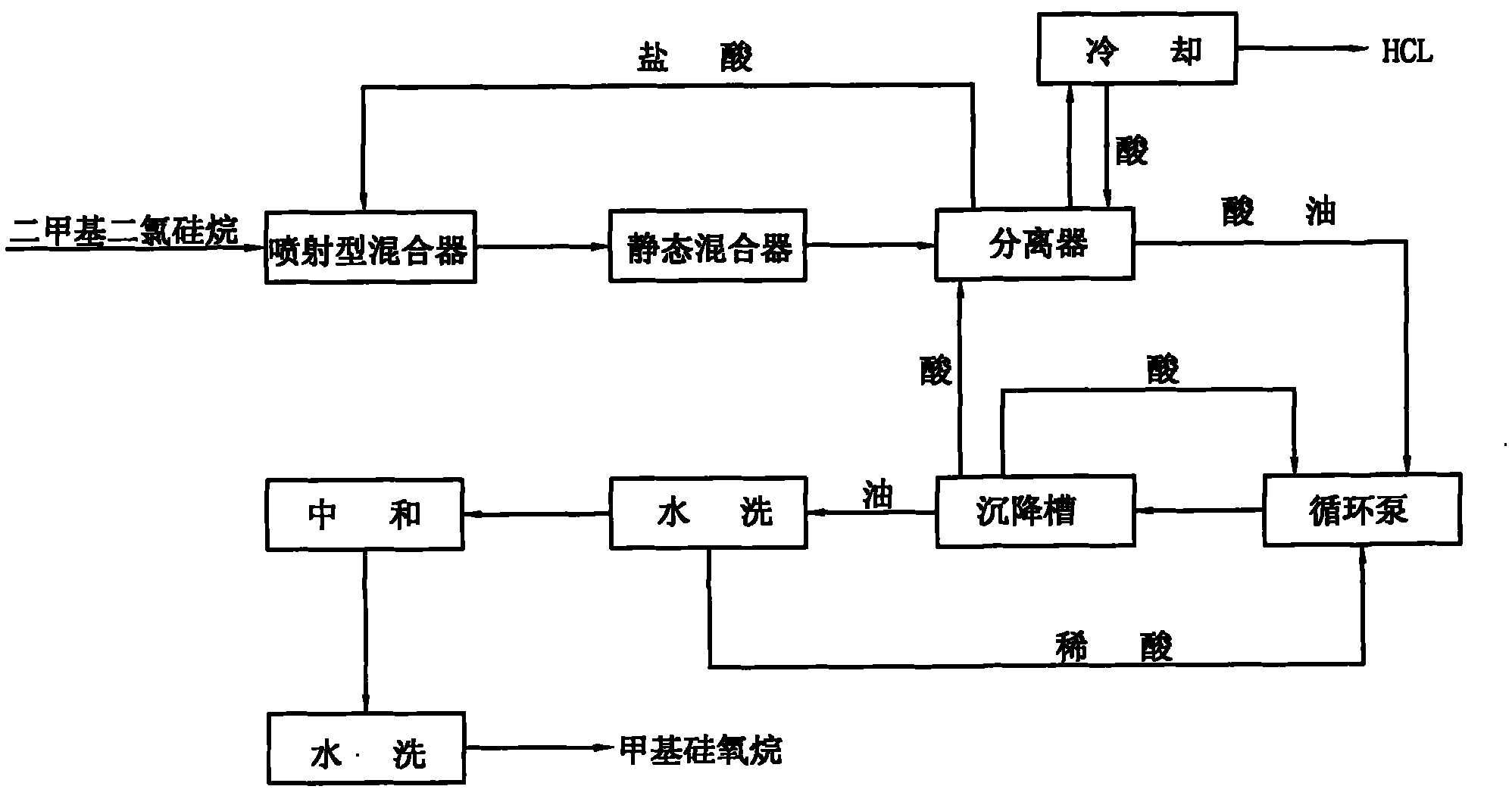

[0027] Concentrated hydrochloric acid circulates between the hydrolysis circulation pump and the separator, and a jet mixer and a static mixer are installed between the circulation pump and the separator. The jet mixer is purchased from the market, and the static mixer is made of graphite, ceramics, glass-lined , plastic or steel-lined plastic materials composed of one or more substances, dimethyl dichlorosilane is continuously fed into the jet mixer after being metered by a flow meter, and the concentrated hydrochloric acid circulation volume flow rate and dimethyl dichlorosilane in the jet mixer The volume flow ratio of dichlorosilane is 40:1; the mixed material undergoes a hydrolysis reaction at 40°C in a static mixer to generate methyl siloxane and gaseous hydrogen chloride, and the reaction mixture flows out of the static mixer and enters the gravity settling The gas-liquid separator performs three-phase separation of oil, acid and gas, and the gaseous hydrogen chloride ma...

Embodiment 2

[0030] Dimethyldichlorosilane is continuously fed into the jet mixer after being metered by a flowmeter. The volume flow ratio of concentrated hydrochloric acid circulation in the jet mixer to the volume flow ratio of dimethyldichlorosilane is 60:1; The hydrolysis reaction occurs in the mixer at 80°C, and the hydrolysis generates methyl siloxane and gaseous hydrogen chloride; the reaction mixture flows out of the static mixer and enters the gravity sedimentation gas-liquid separator for three-phase separation of oil, acid and gas, and the gaseous hydrogen chloride makes the separation The air pressure in the device reaches 0.4MPa (gauge pressure); when the gauge pressure is 0.4MPa, the mass concentration of circulating concentrated hydrochloric acid is 50%. The acid separated by the separator is returned to the hydrolysis circulation pump; the oil enters the atmospheric pressure hydrolysis system; the hydrogen chloride gas is cooled to remove water, purified and then sent to th...

Embodiment 3

[0033] Dimethyldichlorosilane is continuously fed into the jet mixer after being metered by a flowmeter. The volume flow ratio of concentrated hydrochloric acid circulation in the jet mixer to the volume flow ratio of dimethyldichlorosilane is 20:1; The hydrolysis reaction occurs in the mixer at 0°C, and the hydrolysis produces methyl siloxane and gaseous hydrogen chloride; the reaction mixture flows out of the static mixer and enters the gravity sedimentation gas-liquid separator for three-phase separation of oil, acid and gas, and the gaseous hydrogen chloride makes the separation The air pressure in the device reaches 0.1MPa (gauge pressure); when the gauge pressure is 0.1MPa, the mass concentration of circulating concentrated hydrochloric acid is 45%. The acid separated by the separator is returned to the hydrolysis circulation pump; the oil enters the atmospheric pressure hydrolysis system; the hydrogen chloride gas is cooled to remove water, purified and then sent to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com