Flower-like copper oxide catalyst and preparation method and application thereof

A copper oxide, catalyst technology, applied in the direction of copper oxide/copper hydroxide, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve unfavorable large-scale production, no relevant reports, Accelerate the reaction speed and other problems to achieve the effect of being conducive to industrial synthesis, simple preparation process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Weigh 1.0gCu(NO 3 ) 2 ·3H 2 O was dissolved in 50.0ml of absolute ethanol (the concentration of copper ions was 0.08mol / L), and 30.0ml of concentrated ammonia water (commercially available mass fraction was 25-28wt%), 0.4g of NaOH and 5.0g of NaNO were sequentially added at room temperature 3 , after stirring for 30 minutes, a clear and transparent blue solution (ammonia concentration 6.2mol / L, NaOH concentration 0.1mol / L, NaNO 3 Concentration 0.7mol / L), and then transferred to a 150ml stainless steel reactor lined with polytetrafluoroethylene, heated to 130°C for 18h. After the reaction, the black product was filtered, washed five times with water and absolute ethanol, and dried in a vacuum oven at 60° C. for 8 hours to obtain 0.3 g of copper oxide catalyst with a yield of 90.9 wt%.

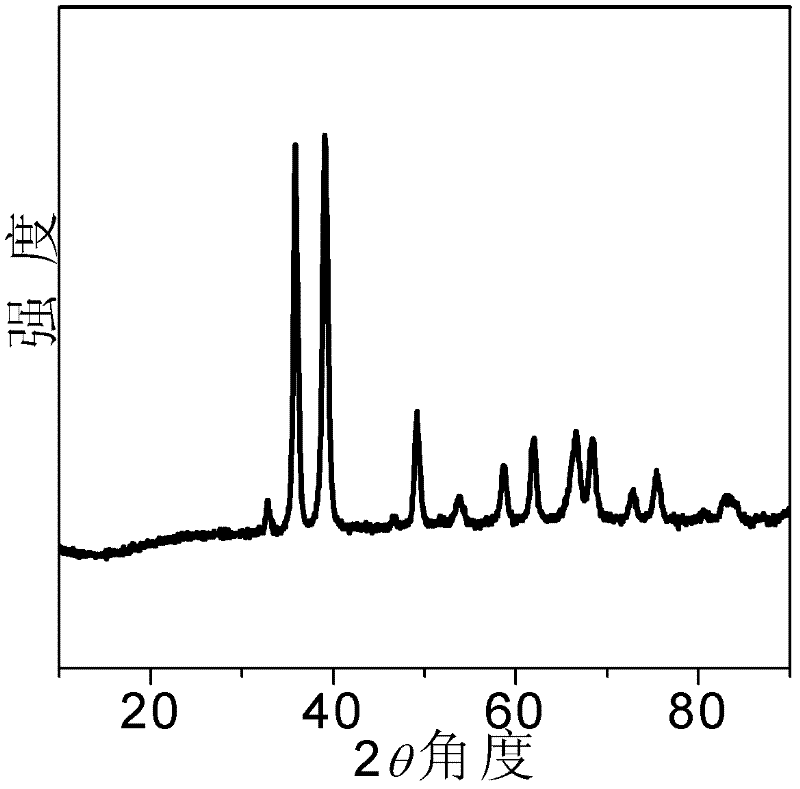

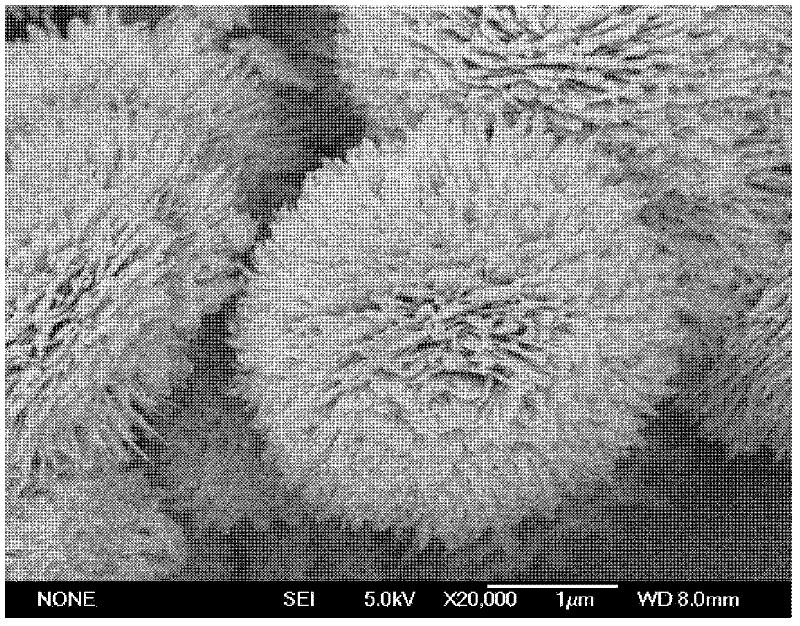

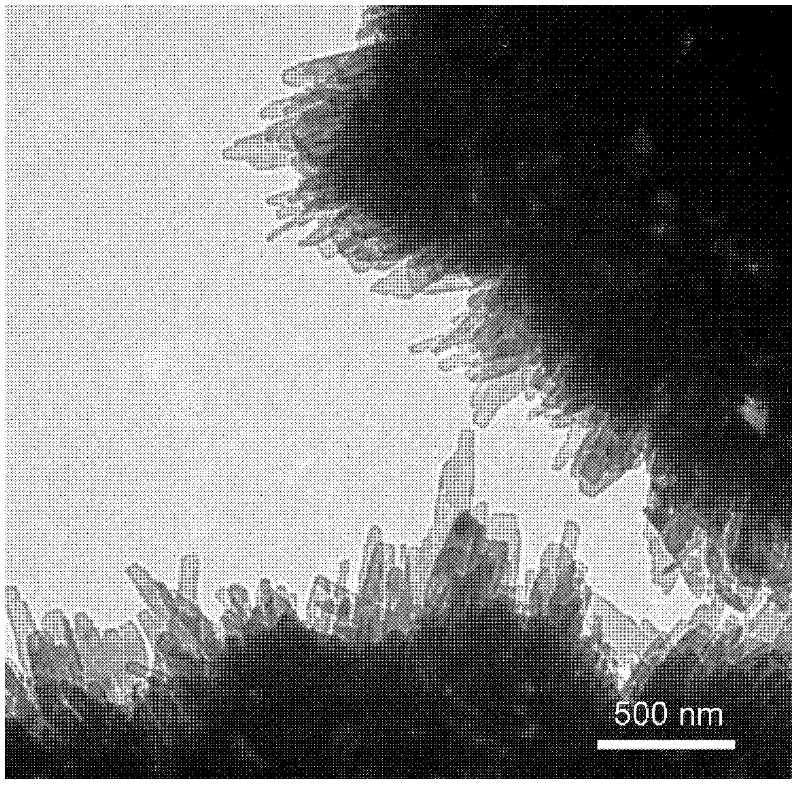

[0038] The copper oxide catalyst material prepared above was subjected to an XRD test on an X'Pert PRO MPD multifunctional X-ray diffractometer produced by Panalytical Company of the N...

Embodiment 2

[0043] Weigh 0.2gCu(NO 3 ) 2 ·3H 2 O was dissolved in a mixed solvent of 28.0ml of absolute ethanol and 22.0ml of water (copper ion concentration was 0.02mol / L), and 22.0ml of concentrated ammonia water (25-28wt%), 0.3g of NaOH and 2.8g of NaNO were sequentially added at room temperature 3 , after stirring for 30 minutes, a clear and transparent blue solution (ammonia concentration 5.0mol / L, NaOH concentration 0.1mol / L, NaNO 3 Concentration 0.5mol / L), and then transferred to a 150ml stainless steel reactor lined with polytetrafluoroethylene, heated to 80°C for 48h. After the reaction, the black product was filtered, washed five times with water and absolute ethanol, and dried in a vacuum oven at 60° C. for 8 hours to obtain 0.05 g of copper oxide catalyst with a yield of 91.0 wt%. XRD spectrum analysis shows that the crystal structure of the product is cubic crystal system CuO. SEM photos show that the morphology of copper oxide presents a flower-like structure, and the flo...

Embodiment 3

[0045] Weigh 12.1gCu(NO 3 ) 2 ·3H 2 O was dissolved in a mixed solvent of 2.5ml absolute ethanol and 47.5ml water (copper ion concentration was 1.0mol / L), and 77.2ml concentrated ammonia water (25-28wt%), 10.2gNaOH and 21.6gNaNO were added successively at room temperature 3 After stirring for 30 minutes, a clear and transparent blue solution (ammonia concentration 10.0mol / L, NaOH concentration 2.0mol / L, NaNO3 concentration 2.0mol / L) was obtained, and then transferred to a 150ml stainless steel reactor lined with polytetrafluoroethylene , heated to 160°C for 0.25h. After the reaction, the black product was filtered, washed five times with water and absolute ethanol, and dried in a vacuum oven at 60° C. for 8 hours to obtain 3.8 g of copper oxide catalyst with a yield of 95.0 wt%. XRD spectrum analysis shows that the crystal structure of the product is cubic CuO. SEM photos show that the morphology of copper oxide presents a flower-like structure, and the flower-like particle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com