Method for preparing polysiloxane by hydrolyzing dimethyl dichlorosilane

A technology of dimethyldichlorosilane and polyorganosiloxane, which is applied in the field of preparing polyorganosiloxane by hydrolysis of dimethyldichlorosilane, can solve the problem that it is difficult to obtain a stable effect viscosity and does not involve the recovery of by-product HCl gas. Purification, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

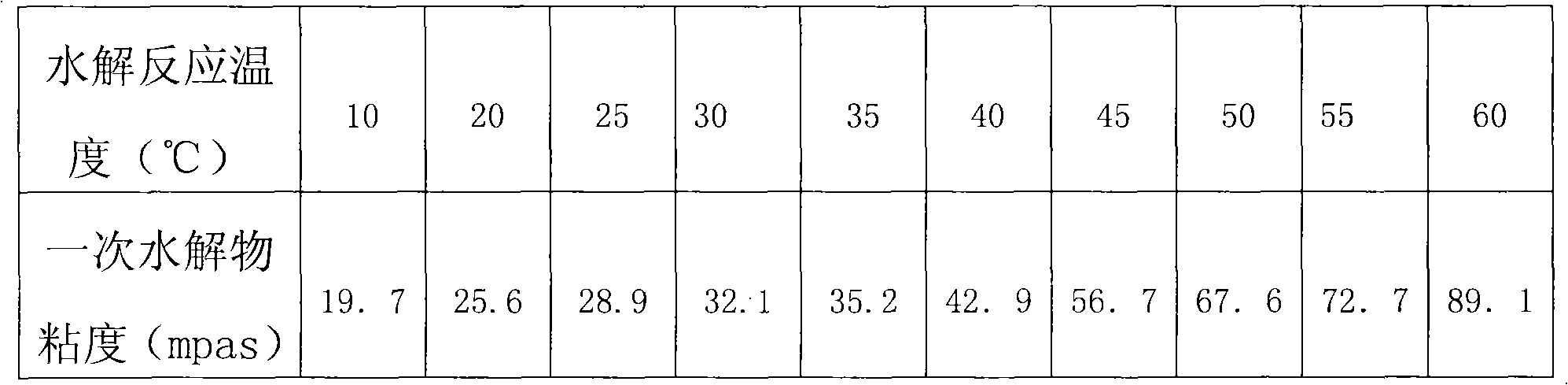

[0031] Introduce dimethyldichlorosilane, concentrated hydrochloric acid, and dilute acid produced by secondary hydrolysis into the metering tank, turn on the acid circulation pump and feed them into the primary hydrolysis reactor at a ratio of 1:1.5:1 (wt), to carry out the hydrolysis reaction. Open the steam valve, adjust the temperature of the heat exchanger, control the hydrolysis temperature between 10°C and 60°C, and measure the viscosity change of the primary hydrolyzate produced at different hydrolysis temperatures. See Table 1.

[0032] Table 1 Different reaction temperatures correspond to different primary hydrolyzate viscosities

[0033]

Embodiment 2

[0035] At 10°C, introduce dimethyldichlorosilane monomer, saturated concentrated hydrochloric acid and dilute hydrochloric acid produced by secondary hydrolysis into the primary hydrolysis reactor, dimethyldichlorosilane monomer, saturated concentrated hydrochloric acid and secondary hydrolysis produce The dilute hydrochloric acid ratio is 1:1.5:0.5~1:1.5:3. The influence of different mass ratios of reactants on the decomposition rate of dimethyldichlorosilane was determined. See Table 2.

[0036] Table 2 Different ratios of reactants correspond to different decomposition rates of dimethyldichlorosilane

[0037] The ratio of dimethyldichlorosilane to dilute hydrochloric acid

Embodiment 3

[0039]At 60°C, introduce dimethyldichlorosilane monomer, saturated concentrated hydrochloric acid and dilute hydrochloric acid produced by secondary hydrolysis into the primary hydrolysis reactor, and dimethyldichlorosilane monomer, saturated concentrated hydrochloric acid and secondary hydrolysis produce The dilute hydrochloric acid ratio is 1:1.5:0.5~1:1.5:3. The influence of different mass ratios of reactants on the decomposition rate of dimethyldichlorosilane was determined. See Table 3.

[0040] Table 3 Different ratios of reactants correspond to different decomposition rates of dimethyldichlorosilane

[0041] The ratio of dimethyldichlorosilane monomer to dilute hydrochloric acid

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com