Continuous hydrolysis process of organic dichlorosilane

A technology of dichlorosilane and polyorganosiloxane, applied in the direction of silicon organic compounds, etc., which can solve the problems of inability to obtain hydrogen chloride, difficult handling, and incomplete hydrolysis of alkyl halosilanes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

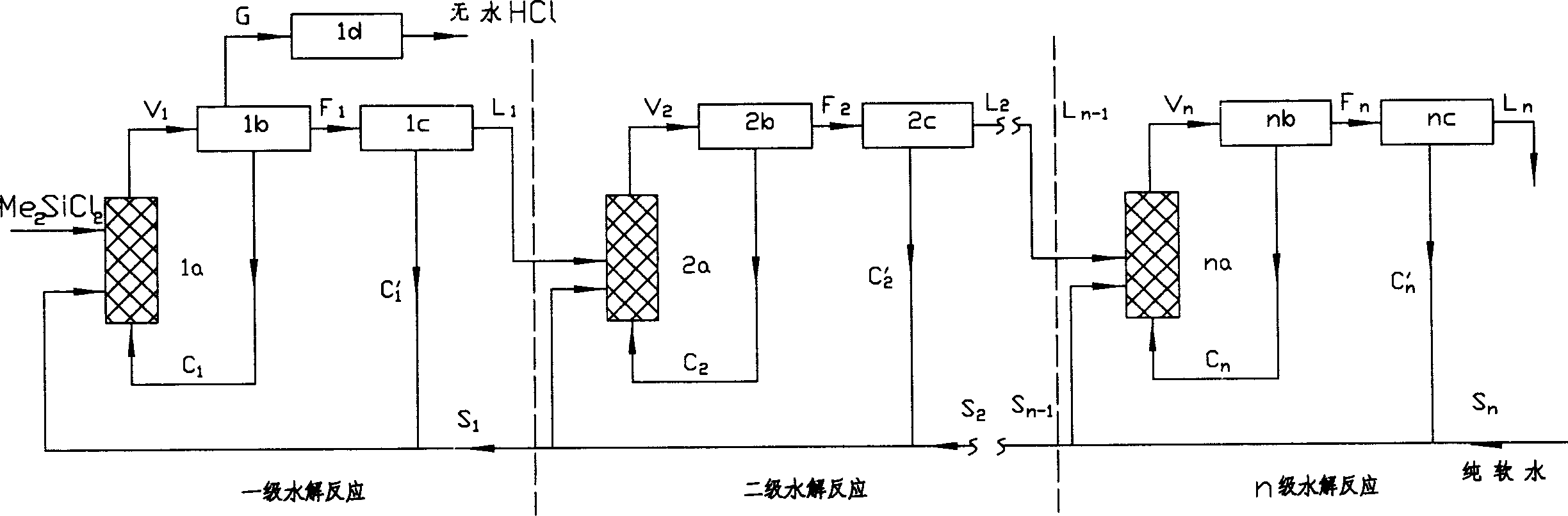

[0029] The first stage hydrolysis reaction:

[0030] System pressure control P=0.4mpa (absolute pressure) Reaction temperature T=50℃

[0031] Me 2 SiCl 2Feed 400Kg / h Internal circulation C 1 = 4m 3 / hr External circulation volume C 1 '=1.5m 3 / hr,R 1 =2.67

[0032] C 1 'The hydrochloric acid concentration 45.6% (titration method is measured), the flow 198Kg / hr of gas phase HCl (G),

[0033] S 1 The flow rate is 70.0Kg / hr, and the concentration of hydrochloric acid is 24.6%.

[0034] Flow rate of crude siloxane (L1): 231.5Kg / hr, chlorine content 4.6%, viscosity 4.3mpa.s.

[0035] Second stage hydrolysis reaction:

[0036] System pressure P=0.1mpa (absolute pressure), reaction temperature T=30°C

[0037] L 1 Feed Internal circulation C 2 =2.5m 3 / hr External circulation volume C 2 '=1.0m 3 / hr R 2 =2.5

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com