Cation, reactnig silicone coloring fixing agent and preparing method thereof

A reactive, color-fixing agent technology, applied in dyeing, organic chemistry, chemical instruments and methods, etc., can solve the problems of little improvement in soaping fastness, reduced light fastness, poor hot water fastness, etc. Achieve good color fixing effect, improve wet treatment fastness, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

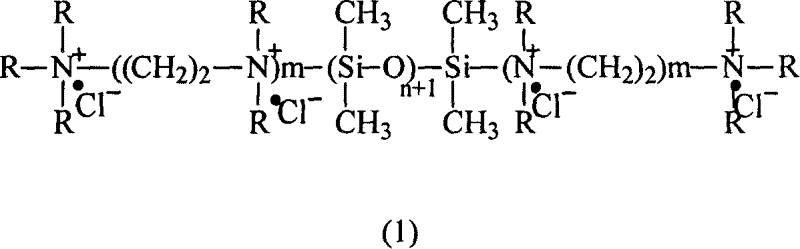

[0033] The synthetic fixing agent structure is:

[0034]

[0035] where R is -CH 2 CH 2 CH 2 Si(OCH 3 ) 3

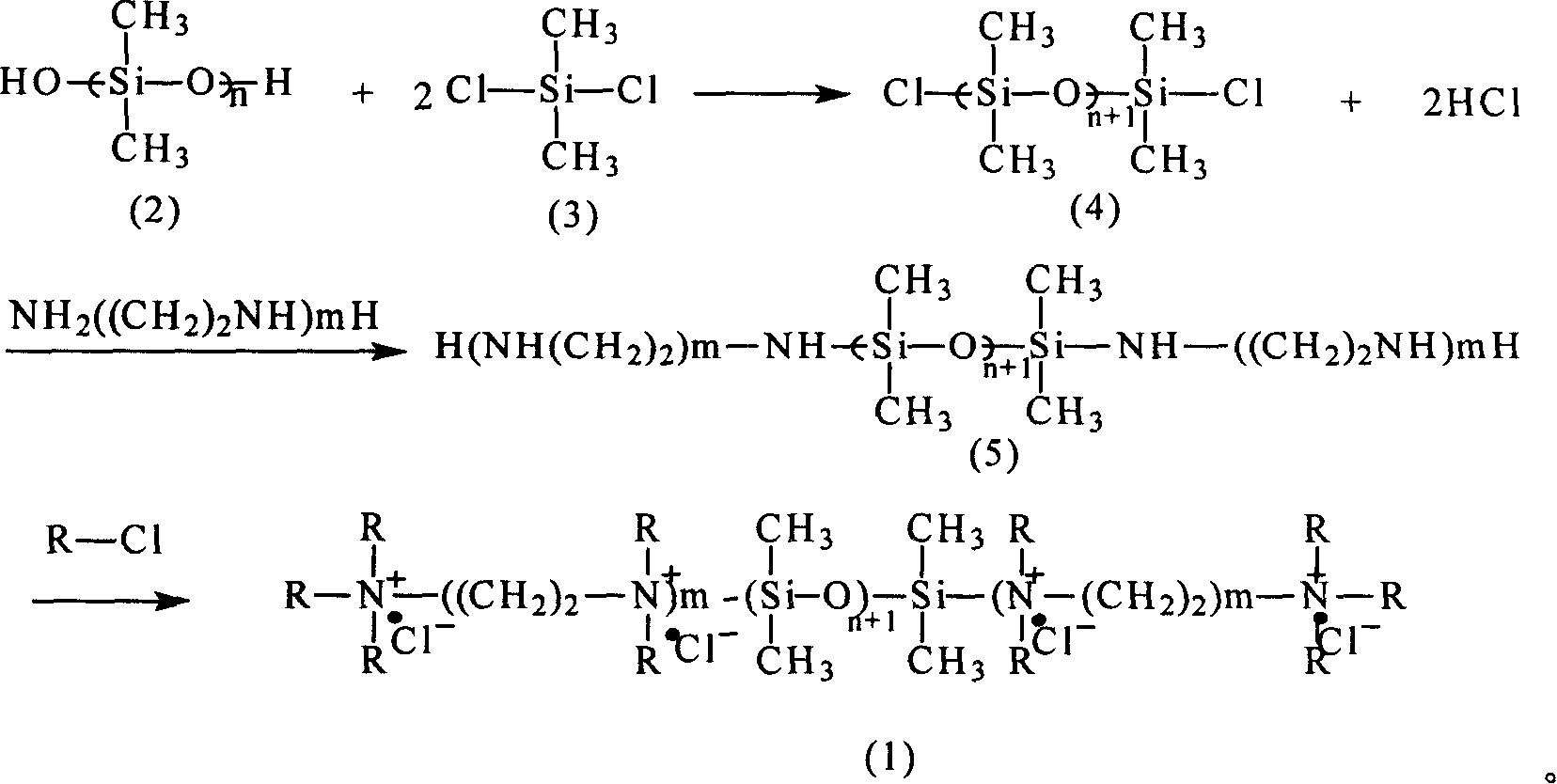

[0036] 1. Synthesis of chlorinated silicone oil:

[0037] Add 0.10 mol of hydroxysilicone oil (n=4) into the three-necked flask, add 0.20 mol of dimethyldichlorosilane into the dropping funnel, stir at 40°C, and slowly add dimethyldichlorosilane, at this time It can be observed that the liquid in the three-necked bottle will bubble, and a large amount of HCl white gas will be generated during the reaction. After the gas is removed, a colorless or light yellow liquid is obtained.

[0038] 2. The reaction between chlorosilicone oil and amine:

[0039]Add 0.04mol of triethylenetetramine (m=2) in the there-necked flask, stir at room temperature, and dropwise add 0.01mol of chlorine-containing silicone oil (n=4) with the dropping funnel, at this moment, white mist is produced in the bottle, and Accompanied by the formation of a large amount of white salt, after a p...

Embodiment 2

[0044] The synthetic fixing agent structure is:

[0045]

[0046] In the formula: R-CH 2 CH 2 CH 2 CH 2 CH 2 Si(CH 3 ) 3

[0047] 1. Synthesis of chlorinated silicone oil:

[0048] Add 0.10mol of hydroxysilicone oil (n=6) into the three-necked flask, add 0.20mol of dimethyldichlorosilane into the dropping funnel, stir at 150°C, and slowly add dimethyldichlorosilane, at this time It can be observed that the liquid in the three-necked bottle will bubble, and a large amount of HCl white gas will be generated during the reaction. After the gas is removed, a colorless or light yellow liquid is obtained.

[0049] 2. Reaction of chlorosilicone oil with amine

[0050] Add 0.04 mol of triethylenetetramine (m=3) into the three-necked flask, stir at room temperature, and drop 0.01 mol of chlorine-containing silicone oil with the dropping funnel. At this time, white mist is produced in the bottle, accompanied by a large amount of white The salt is formed, and after a period o...

Embodiment 3

[0055] The synthetic fixing agent structure is:

[0056]

[0057] In the formula: R is -CH 2 CH 2 CH 2 Si(OC2H 5 ) 3

[0058] 1. Synthesis of chlorinated silicone oil:

[0059] Add 30ml of ethanol and 0.10mol of hydroxy silicone oil (n=8) into the three-necked flask, add 0.20mol of dimethyldichlorosilane into the dropping funnel, stir at 80°C, and slowly add dimethyldichlorosilane , a large amount of HCl white gas is produced during the reaction, and the gas is removed to obtain a colorless or light yellow viscous liquid.

[0060] 2. Reaction of chlorosilicone oil with amine

[0061] Add 50ml of ethanol into the three-neck flask, stir at room temperature, and pass through ammonia gas (m=0), and at the same time, drop 0.01mol of chlorine-containing silicone oil with the dropping funnel, at this time, white mist is generated in the bottle, accompanied by a small amount of white After a period of time, the white mist gradually disappears, which is due to the action of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com