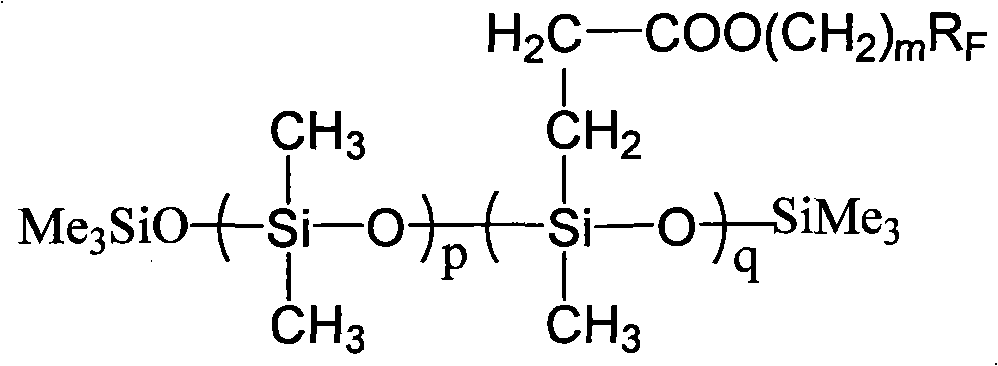

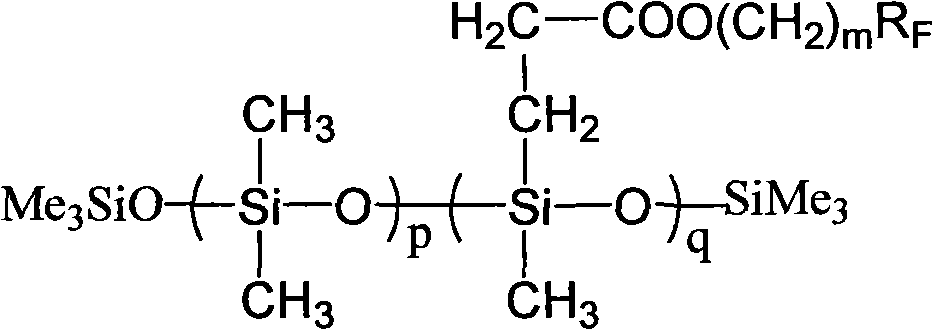

Preparation method of fluorosilicon oil with high-efficiency defoaming performance

A fluorine-containing silicone oil, defoaming technology, applied in chemical instruments and methods, foam dispersion/prevention, dissolution, etc., can solve the problems of inapplicable oil phase system, low surface free energy, weak defoaming performance of silicone oil, etc. Good defoaming and anti-foaming effect, high surface energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

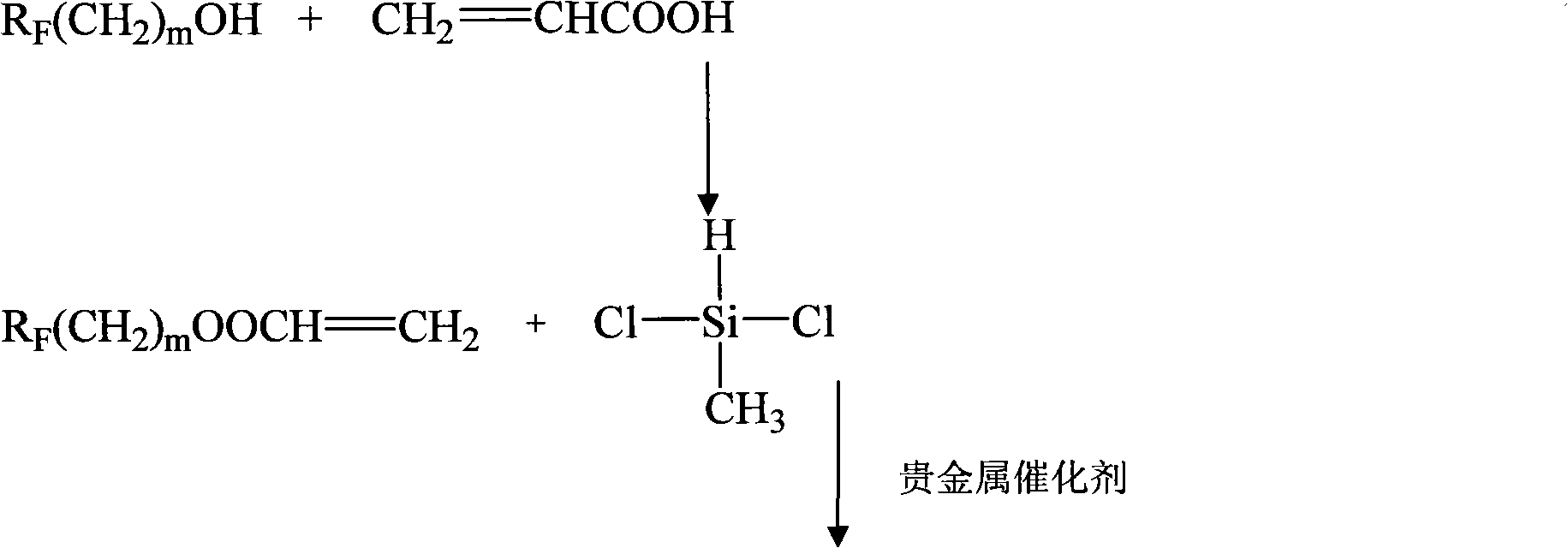

Method used

Image

Examples

Embodiment 1

[0023] ① In this example, acrylic acid and 1H, 1H, 2H, 2H-perfluorodecyl alcohol were used as raw materials to synthesize 1H, 1H, 2H, 2H-perfluorodecyl alcohol acrylate:

[0024] A 500ml four-necked flask is equipped with stirring, thermometer, reflux condenser and constant pressure addition funnel respectively. According to the weight ratio, add 40 parts of 1H, 1H, 2H, 2H-perfluorodecanol, 10 parts of acrylic acid and 50 parts of Solvent toluene, use 2 parts of concentrated sulfuric acid as catalyst, react at reflux temperature 90°C for 5.5h; neutralize the reaction product with sodium bicarbonate after the reaction, wash with water until neutral, then dry with anhydrous sodium sulfate, and finally depressurize Distillation to obtain 1H, 1H, 2H, 2H-perfluorodecyl alcohol acrylate; the product is a light yellow transparent liquid with a yield of 68%; product analysis results: FT-IR (KBr), v / cm -1 : 1272(v C-F ), 1638 (v C=C ), 1728 (v C=O ), 1189 (v C-O ), 2926 (v- CH2- )...

Embodiment 2

[0033] According to the reaction method provided in Example 1, 1H, 1H, 2H, 2H-perfluorodecylcarbonylpropyl-methyl silicone oil was synthesized; in the esterification reaction, 30 parts of 1H, 1H, 2H, 2H-perfluoro Decyl alcohol, 5 parts of acrylic acid and 55 parts of solvent benzene, with 1 part of methanesulfonic acid as a catalyst, reacted at a reflux temperature of 110°C for 5 hours, and the yield was 60%; the addition reaction was reacted at 130°C for 3 hours, and the yield was 75% %; for the cyclization reaction, 20 parts of fluorine-containing dichlorosilane and 10 parts of calcium oxide were reacted for 2 hours; for the ring-opening reaction, the reaction was carried out at 80° C. for 12 hours, and the yield was 77%.

Embodiment 3

[0035] According to the reaction method provided in Example 1, 1H, 1H, 2H, 2H-perfluorodecylcarbonylpropyl-methyl silicone oil was synthesized; in the esterification reaction, 50 parts of 1H, 1H, 2H, 2H-perfluoro Decyl alcohol, 15 parts of acrylic acid and 45 parts of solvent thionyl chloride, with 4 parts of cyclohexane as a catalyst, reacted at a reflux temperature of 70°C for 6 hours, and the yield was 62%; among them, the addition reaction was carried out at 80°C for 7 hours, The yield is 76%; among them, cyclization reaction, 26 parts of fluorine-containing dichlorosilane, and 10 parts of manganese dioxide are reacted for 3 hours; among them, the ring-opening reaction is reacted at 90° C. for 10 hours, and the yield is 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com