Red wine fermentation circulating device

A circulation device and technology for red wine, applied in the preparation of wine, preparation of alcoholic beverages, biochemical equipment and methods, etc. Reasonable way, good loop effect, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

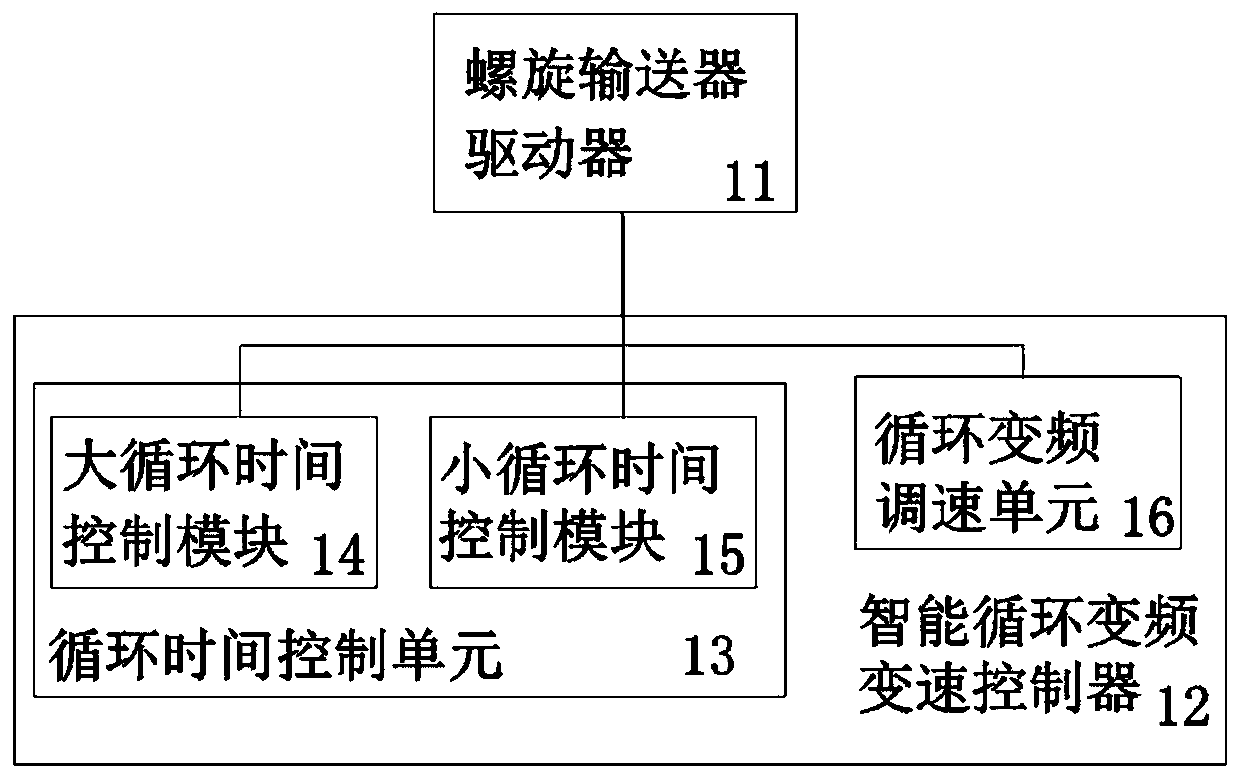

[0022] In embodiment 2, a cycle process implements 4 shifts, each 4-5 minutes, each shift speed is the same. The remaining structures and corresponding operation control methods of this example can be similar to those of the above-mentioned embodiment.

[0023] In embodiment 3, its cycle frequency conversion speed regulation unit corresponds to 2 different variable speeds respectively, controls the different speeds of the second repeated beating cycle in the small cycle cycle of each material beating cycle of the large cycle period by it, and each time The number of repetitions of variable speed in the repeated beating cycle process is 2-4 times.

[0024] In this example, the large cycle time control module controls the number of times that the material is cycled every day to 4 times. The small cycle time control module controls the number of repetitions of each material beating cycle in the small cycle period to be 2 times. That is to say, the material is beaten 4 times a d...

Embodiment 4

[0025] In Embodiment 4, the controller of the screw conveyor is a manual relay delay switch control circuit. Each material beating cycle in a day is started by a manual switch, and the delay relay of the switch control circuit realizes the time length of each beating cycle. Whether or not to repeat each material punching cycle in a day, or the number of repetitions, can be completed by the number of manual starts. The remaining structures and corresponding operation control methods of this example can be similar to any of the above-mentioned embodiments.

Embodiment 5

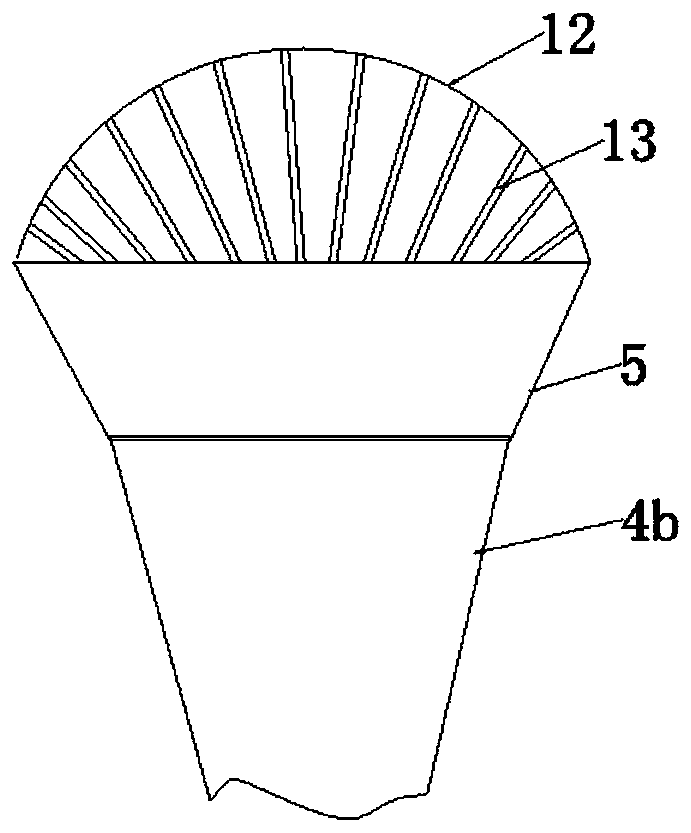

[0026] Example 5. The present invention also includes range sprinklers, such as image 3 As shown, a split-range sprinkler 12 is connected to the distributing horn mouth 5, and the split-range sprinkler 12 is in the shape of an arch (or steamed bun), and its lower end is a plane, and the split-range sprinkler is uniform on its radial plane Distributing and sprinkling holes 13 are arranged, and the sprinkling and sprinkling holes gradually become longer from all around to the center. Due to the change of the path length of the split spraying hole, the spreading distance will be different. The material liquid is spread and covered more evenly. The rest of the structure and corresponding operation control mode of this example can be similar to any of the above-mentioned embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com