Method and equipment for surface treatment by cryogenic fluid jets

A cryogenic fluid, equipment technology, applied in the field of surface treatment, dipping or scraping coated or uncoated materials, can solve other problems such as damage to parts, loss of output and productivity, impact of heat treatment effectiveness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

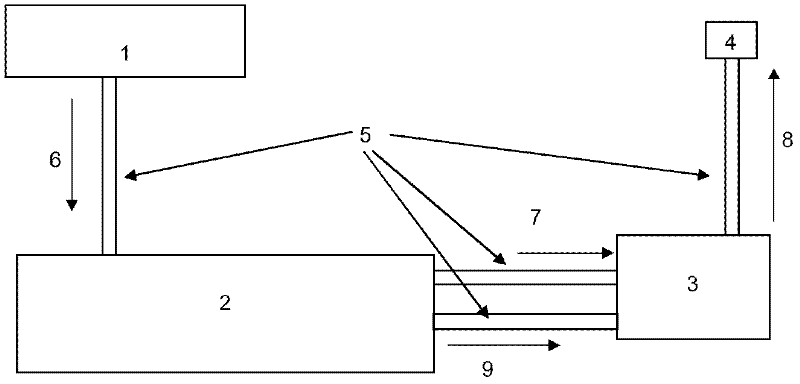

[0041] From figure 1 As can be seen in , equipment for immersion, surface treatment, or similar treatments using cryogenic liquid jets typically includes liquid nitrogen (hereinafter referred to as LN 2 ) storage container 1, such as a tank, which supplies liquid nitrogen to the compression device 2 through a liquid nitrogen supply line 6 at a low pressure—that is, a pressure of about 3 to 6 bar and a temperature of about -180° C. 2 has a compressor and an internal upstream heat exchanger for liquid nitrogen at ultra high pressure (UHP).

[0042] Thus, the compression device 2 is able to compress the LN from the storage vessel 1 2 .

[0043] Next, the LN at the first pressure (UHP) 2 Through transfer line 7 to the external downstream heat exchanger 3 where the ultra-high pressure LN is cooled with liquid nitrogen (in 9) at atmospheric pressure 2 UHP liquid nitrogen is thus usually obtained.

[0044] This leads to LN 2 At a pressure (UHP) generally above 1000 bar, general...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com