Internal inserts in cooling towers

A cooling tower, plug-in technology, applied in water shower coolers, lighting and heating equipment, coatings, etc., can solve the problems of increasing blowers, increasing costs, increasing operating costs, etc., to reduce pollution and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

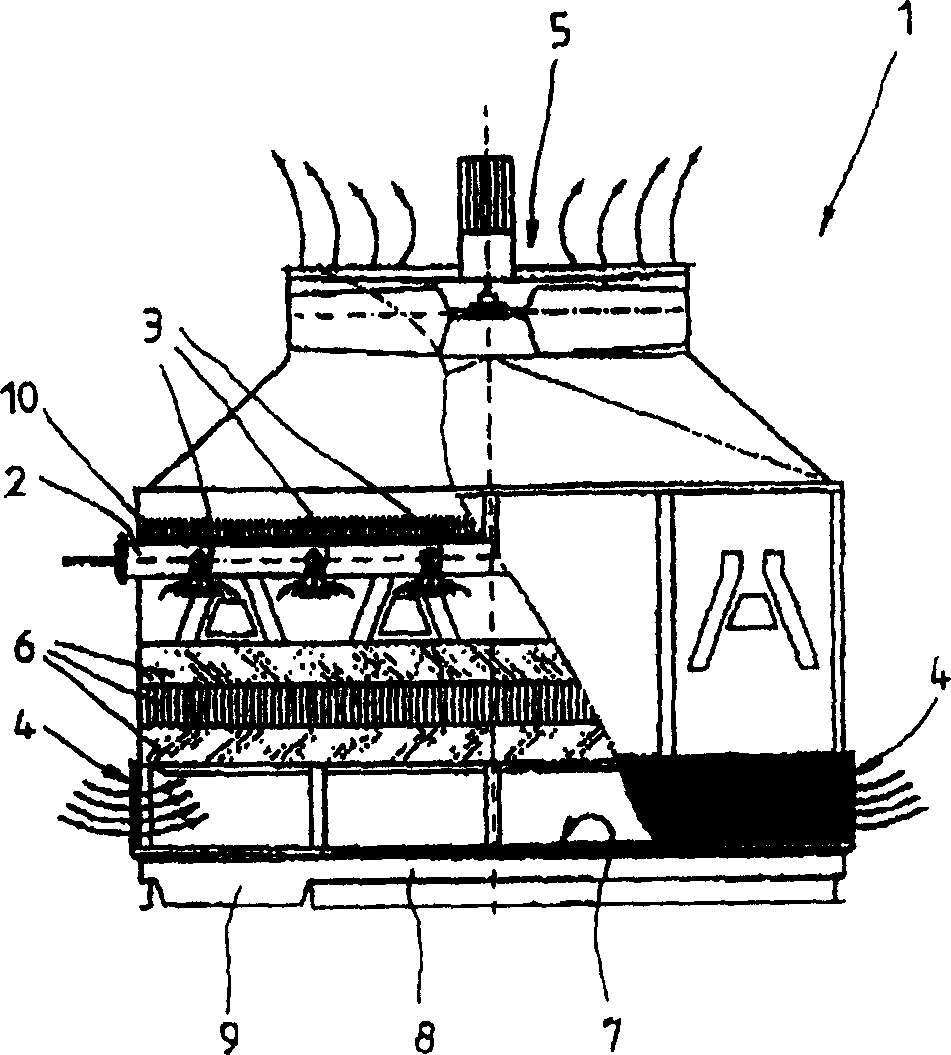

[0023] The figure shows a counterflow cooling tower 1 . The water heated to about 35° C.-40° C. during cooling enters the cooling tower 1 through the pipe 2 and is evenly distributed in the cooling tower 1 through a plurality of nozzles 3 . The air used to cool the water enters the inner space of the cooling tower 1 through the air inlet 4 and is forced through the cooling tower 1 in the opposite direction of the drip flow by the action of the blower 5 .

[0024] Due to the effect of the nozzle 3, the water is sprayed onto the cooling insert 6 like "rain". The cooling insert 6 comprises interconnected drip grids or drip blocks made of plastic. The trickle grid or blocking block forms a three-dimensional network of narrow meshes, and the purpose is to make the trickle drip as slowly as possible in the lattice structure of the cooling insert 6 .

[0025] The cooling insert 6 is swept over by the air flowing in the opposite direction. The water droplets that adhere to the latt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com