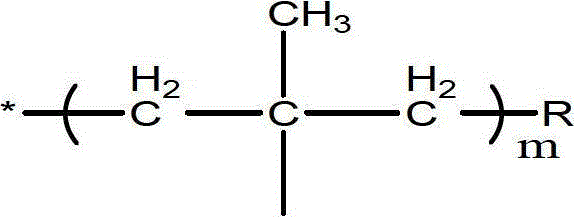

The preparation method of polyisobutylene amine

A technology of polyisobutylene amine and polyisobutylene, which is applied in the field of preparation of polyisobutylene amine, can solve the problems of large equipment investment and high pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

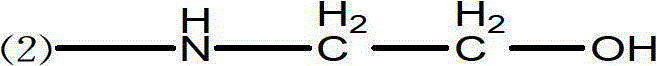

[0035] First, add 100g of high-activity polyisobutylene into the reactor, and then add about 60g of functional solvent polyether into the reactor. , reacted at 70°C for 8h to obtain a product with an epoxy polyisobutylene content of 60%, then, hydrocyclone evaporation removed moisture and acetic acid, added ethanolamine 12.2g and water 1.8g, reacted at 120°C for 12h, and finally rotated Free ethanolamine and water were removed by evaporation, and filtered to obtain the target product with an amine value of 16 mgKOH / g.

Embodiment 2

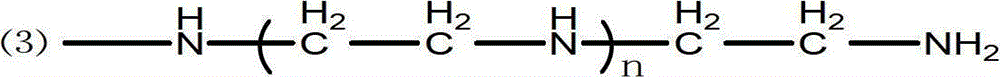

[0037] First, add 100g of high-activity polyisobutylene into the reaction kettle, and then add about 30g of functional solvent oil-soluble polyether into the reaction kettle. , 60g of hydrogen peroxide was evenly added dropwise within 3h, and then reacted at 95°C for 2h to obtain a product with an epoxy polyisobutylene content of 71%. 36g of alcohol was reacted at 200°C for 2h, and finally the free ethylenediamine and isopropanol were removed by hydrocyclone evaporation, and press-filtered to obtain polyisobuteneamine with an amine value of 21mgKOH / g.

Embodiment 3

[0039] First, add 100g of high-activity polyisobutylene into the reaction kettle, and then add about 50g of functional solvent aromatic hydrocarbon mineral spirits into the reaction kettle. Add 30g of hydrogen peroxide evenly dropwise within 2 hours, and then react at 95°C for 2 hours to obtain a product with an epoxy polyisobutylene content of 75%. Then, remove water and acetic acid by hydrocyclone evaporation, and add 146g of ethylenediamine and isopropanol 60 g, reacted at 200° C. for 2 h, and finally removed free ethylenediamine and isopropanol by hydrocyclone evaporation, and press-filtered to obtain polyisobutylene amine with an amine value of 24 mgKOH / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com