Novel crushing device for building

A crushing device and construction technology, applied in the use of liquid separating agent, grain processing, and separation of dispersed particles, etc., can solve the problems of dust pollution, affecting the performance and scope of application of the crushing device, and poor crushing effect, so as to reduce dust Pollution, the effect of adequate and efficient crushing operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

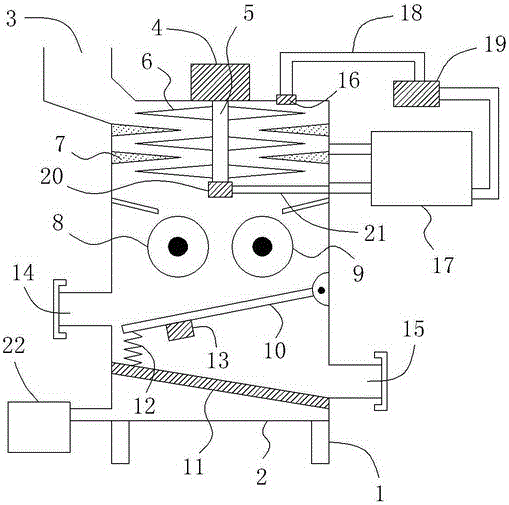

[0013] Such as figure 1 As shown, a new type of construction crushing device includes a bracket 1 and a housing 2 arranged on the bracket 1. A feed port 3 is provided on the top left side of the housing 2. In the housing 2 A motor 4 is also provided at the top of the motor 4, and a rotating shaft 5 is connected to the output shaft end of the motor 4. The rotating shaft 5 is arranged vertically downward and extends to the inside of the housing 2, and on the rotating shaft 5 A plurality of conical stirring rods 6 are evenly distributed, and a plurality of conical protrusions 7 are also evenly distributed on the upper part of the vertical inner wall of the housing 2, and the conical protrusions 7 and the stirring The rods 6 are set crosswise so that the construction waste materials can be effectively primary crushed; the left crushing roller 8 and the right crushing roller 9 are respectively provided under the rotating shaft 5 to further finely crush the construction waste materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com