Electric conduction brush used for solder stripping device and solder stripping device comprising electric conduction brush

A conductive brush and tin stripping technology, applied in the direction of electrolytic components, electrolysis process, etc., can solve the problems that tin is easily oxidized and tin stripping efficiency, PCB substrate is easily corroded, etc., so as to improve the tin stripping effect and speed up the tin stripping rate. , cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The principle of the present invention will be further described in detail below in conjunction with the accompanying drawings and exemplary embodiments, so as to make the technical solution of the present invention clearer.

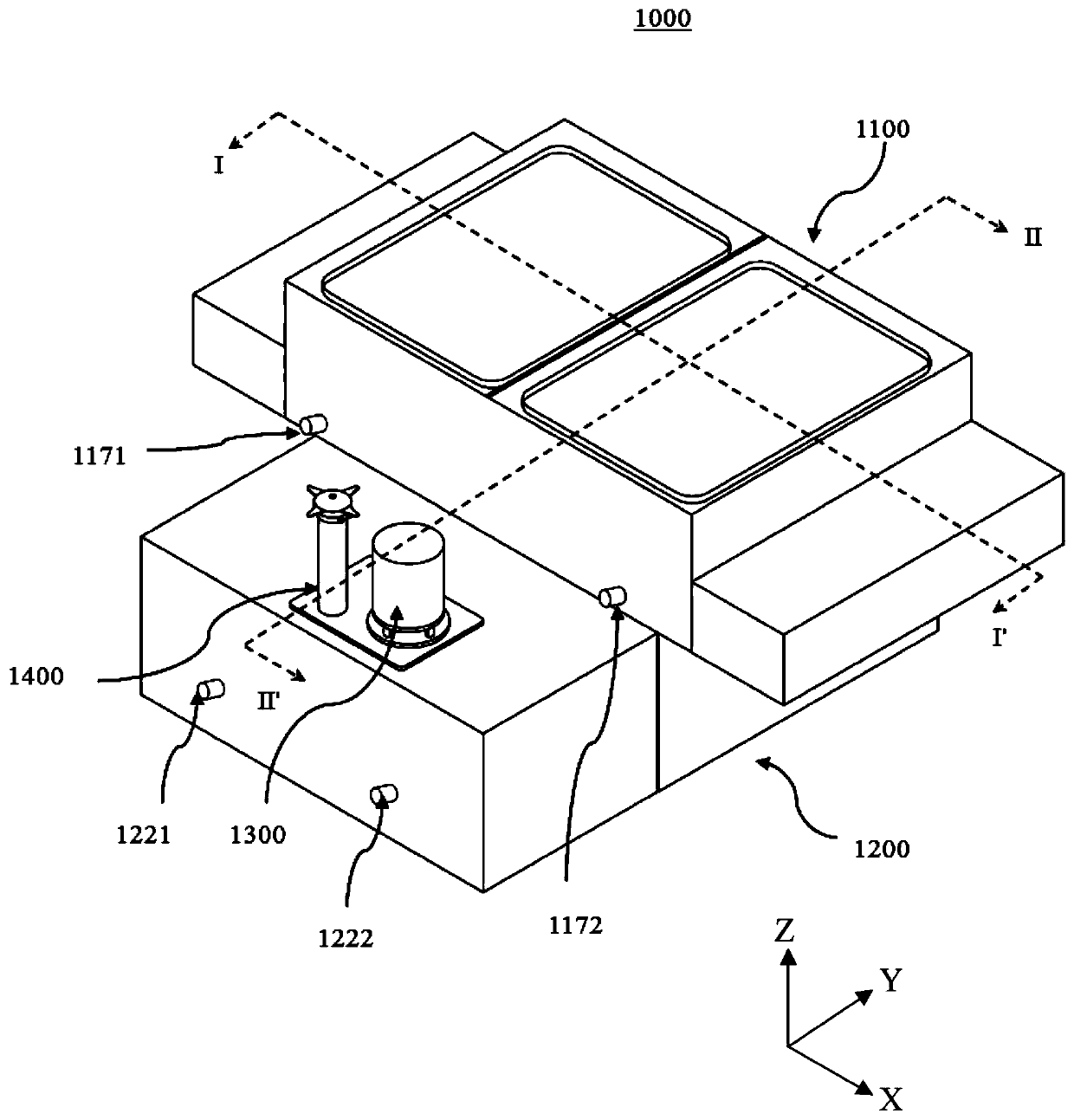

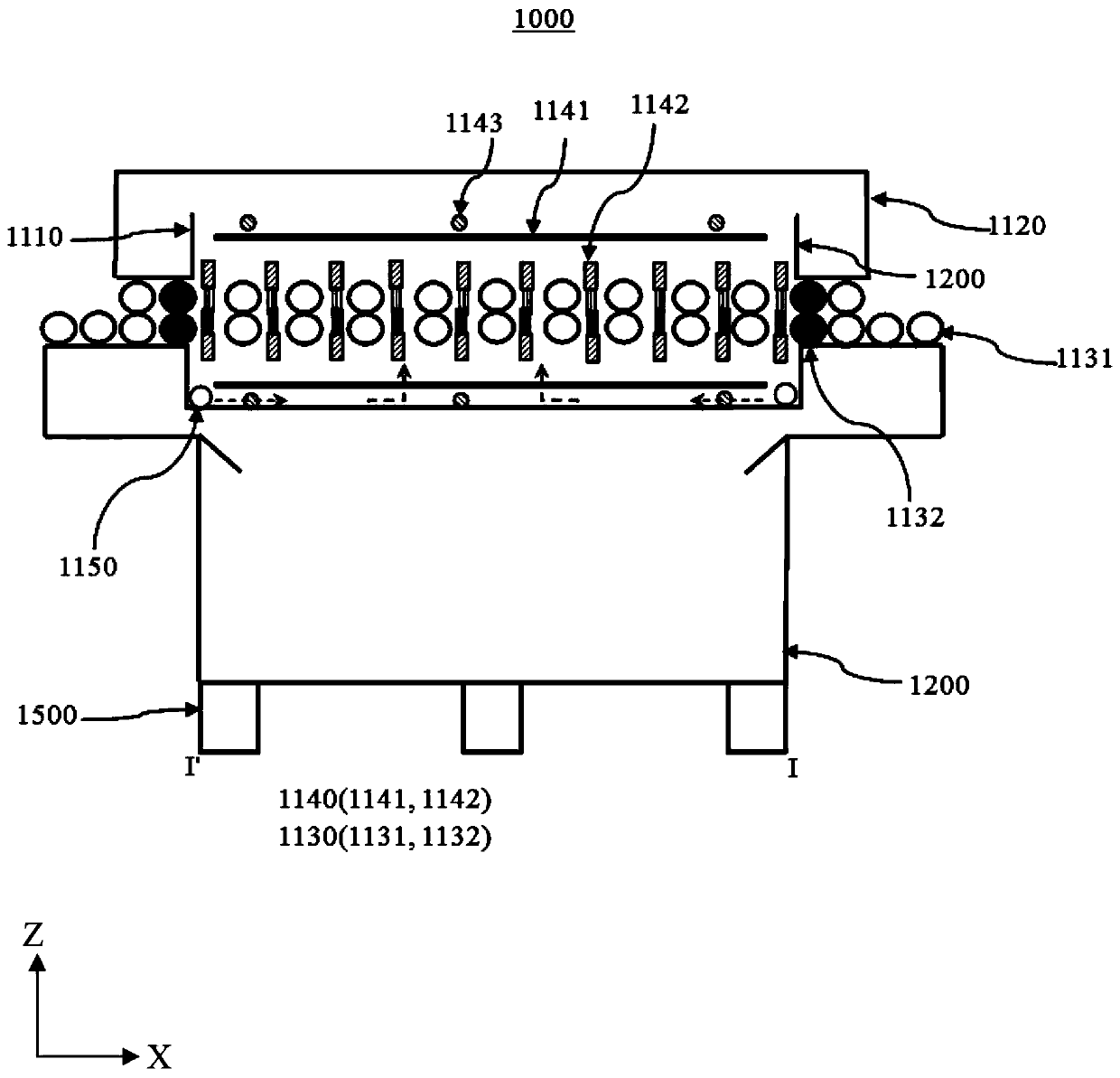

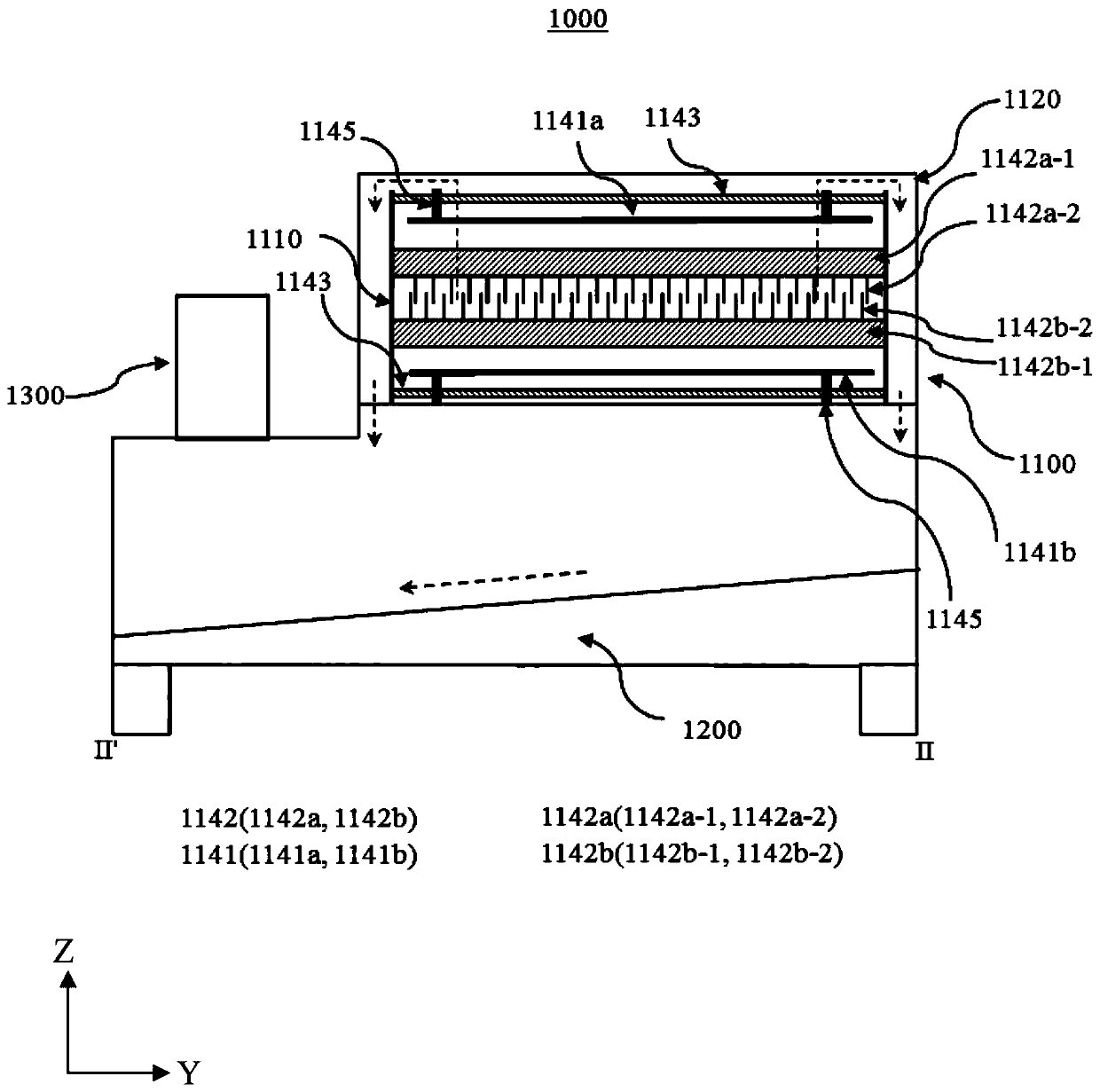

[0024] figure 1 is a perspective view of a desoldering device according to an exemplary embodiment of the present inventive concept. In the drawings, the X-axis, Y-axis and Z-axis are not limited to the three axes of the rectangular coordinate system and can be interpreted in a wider sense. For example, the X-axis, Y-axis, and Z-axis may be perpendicular to each other, or may represent different directions that are not perpendicular to each other.

[0025] refer to figure 1 , The stripping equipment 1000 according to an exemplary embodiment of the present inventive concept may include a stripping tank assembly 1100 and a solution tank 1200 .

[0026] Such as figure 1 As shown in , the stripping tank assembly 1100 may at least partially overlap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com