Release agent, non-silicon release film containing release agent and manufacturing method of non-silicon release film

A technology of release agent and release film, applied in the direction of coating, etc., can solve the problems of difficult uniform coating of coating liquid, uneven thickness of release surface, uneven release force, etc., and achieve low manufacturing cost and excellent appearance , the effect of low release force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

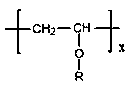

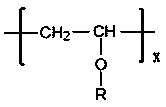

[0031] The proportioning scheme of the release agent: R is -OCONHCnHm, n=18, m=37, x=20;

[0032] Polyvinyl ester-based compound weight ratio: 5%

[0033] Weight ratio of coupling agent: 0.2%

[0034] Toluene weight ratio: 15%

[0035] Xylene weight ratio: 10%

[0036] Isopropanol by weight: 12%

[0037] Heptane weight ratio: 57.8%

[0038] The release agent is coated on the PET base film with a thickness of 30um by gravure coating; the coating moisture is 6g / m 2 ; After coating, the baking temperature is 60°C-130°C, and the baking time is 30 seconds.

[0039] Tested with a spectrometer, the dry film thickness of the release agent coating is 200nm, the release force is 10-30g / inch, and the residual adhesion rate is 92%. The coating layer has good transparency in appearance, no "mottle" and iridescent color difference; after the obtained release film is immersed in toluene solvent and cleaned with ultrasonic waves, the film is taken out and dried naturally, and the origin...

Embodiment 2

[0041] The proportioning scheme of the release agent: R is -CnHm, n=10, m=21, x=20;

[0042] Weight ratio of polyvinyl ester-based compound: 0.3%

[0043] Weight ratio of coupling agent: 0.1%

[0044] Toluene weight ratio: 15%

[0045] Xylene weight ratio: 15%

[0046] Isopropanol weight ratio: 20%

[0047] Heptane weight ratio: 49.6%

[0048] Coating wet weight: 2g / m 2 ,

[0049] PET base film thickness: 30um;

[0050] The baking temperature is 60°C-130°C, and the baking time is 10S;

[0051] The dry film thickness of the release agent coating is 50nm;

[0052] The release force of the prepared release film is 400-500 g / inch, and the residual adhesion rate is 95%;

[0053] After the prepared release film was immersed in toluene solvent and cleaned with ultrasonic waves, the release force of the original release agent-coated surface was measured to be 750-800g / inch, and the release force of the base film without coating release agent treatment was 700-800 g / inch.

Embodiment 3

[0055] The proportioning scheme of the release agent: R is -OCOCnHm, n=13, m=27, x=20;

[0056]Polyvinyl ester-based compound weight ratio: 10%

[0057] Weight ratio of coupling agent: 0.5%

[0058] Toluene weight ratio: 15%

[0059] Xylene weight ratio: 15%

[0060] Isopropanol weight ratio: 15%

[0061] Heptane weight ratio: 44.5%

[0062] Coating wet weight: 5g / m 2 ,

[0063] PET base film thickness: 30um;

[0064] The baking temperature is 60°C-130°C, and the baking time is 70 s.

[0065] The dry film thickness of the release agent coating is 500nm;

[0066] The release force of the prepared release film is 30-70 g / inch, and the residual adhesion rate is 90%;

[0067] After the prepared release film was immersed in toluene solvent and cleaned with ultrasonic waves, the release force of the original release agent coating treatment surface was measured to be 720-760g / inch, and the release force of the base film without coating release agent treatment was 700-800 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com