Shale oil development injection-production system and method

A shale oil injection system technology, applied in the field of energy and environment, can solve the problems of limited pore function in shale oil reservoirs, achieve the effects of overcoming capillary resistance, protecting the natural environment, and solving low development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

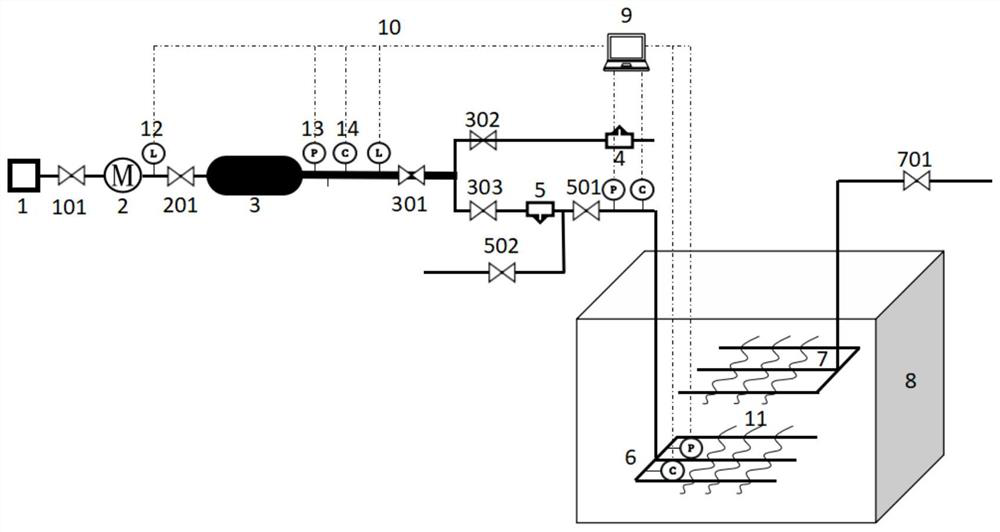

[0033] Such as figure 1 As shown, the outlet end of the deionized water source 1 is connected to the inlet end of the high-pressure metering pump 2 through a high-pressure water delivery pipeline, and a first valve 101 is installed on the high-pressure water delivery pipeline for the connection between the deionized water source 1 and the high-pressure metering pump 2. The on-off control between the high-pressure metering pump 2 and the inlet of the supercritical water generator 3 are connected through a heat-insulating high-pressure water delivery pipeline, and a second valve 201 is installed on the heat-insulation high-pressure water delivery pipeline for The on-off control between the high-pressure metering pump 2 and the supercritical water generator 3, the outlet end of the supercritical water generator 3 is connected with a heat-insulating main pipe, and a bypass pipe is connected to the heat-insulating main pipe, and the heat-insulating main pipe The pipeline is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com